A process for improving the recovery rate of rare earth and the grade of fluorite in tailings

A process method and fluorite technology, applied in solid separation, flotation and other directions, can solve problems such as low recovery rate, and achieve the effect of improving fluorite grade and rare earth recovery rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] In the present embodiment, the technological method of improving rare earth recovery rate and fluorite grade in the tailings comprises the following steps:

[0051] 1) Mixed flotation

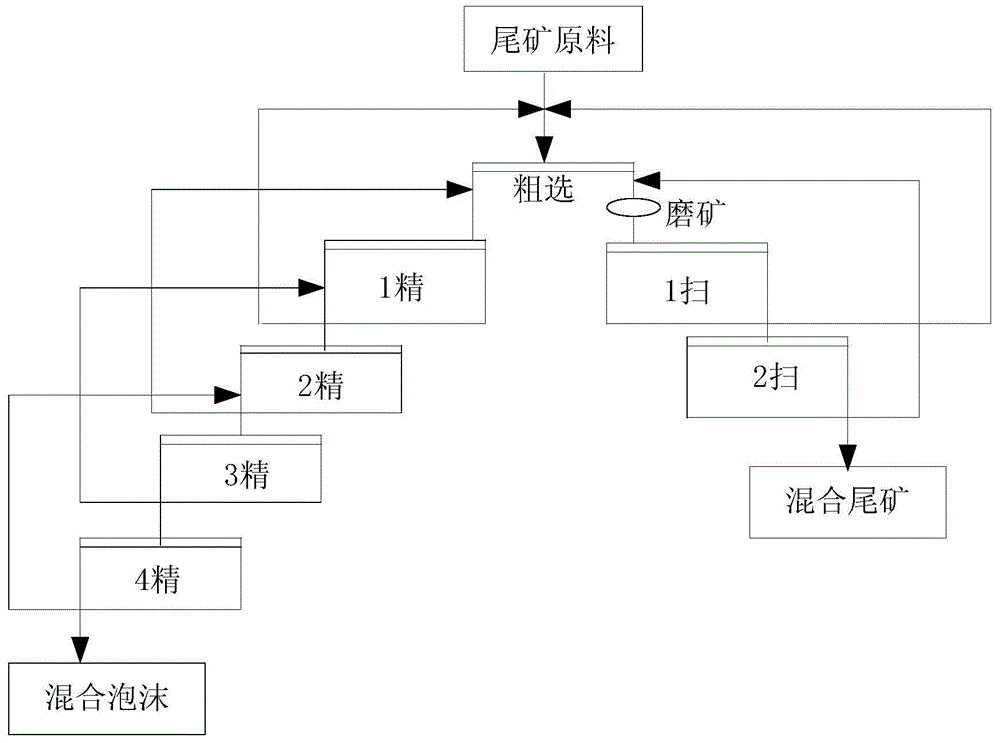

[0052] Such as figure 1 Shown is the flow chart of the mixed flotation process; in the mixed flotation process, the pH is 10-11, and the temperature is 25°C. Mixed flotation includes a rough selection, a second sweep and four refinements.

[0053] Roughly select 250g of Baiyan Obo tailings with a REO grade of 7.00% or more and a fluorite grade of 11.5% or more, and add Na 2 CO 3 30ml, water glass 20ml, and collector 50ml to obtain the roughing concentrate and roughing tailings, and the roughing concentrate continues to be selected for the first stage.

[0054] The rougher tailings are ground, and the particle size reaches -200 mesh, accounting for more than 96.8%.

[0055] The tailings after grinding are subjected to the first-stage scavenging, adding 10ml of water glass and 20ml of...

Embodiment 2

[0083] In the present embodiment, the technological method of improving rare earth recovery rate and fluorite grade in the tailings comprises the following steps:

[0084] 1) Mixed flotation

[0085] Such as figure 1 Shown is the flow chart of the mixed flotation process. In the mixed flotation process, the pH is 10-11 and the temperature is 30°C. Mixed flotation includes a rough selection, a second sweep and four refinements.

[0086] Roughly select 250g of Baiyan Obo tailings with a REO grade of 7.00% or more and a fluorite grade of 11.5% or more, and add Na 2 CO 3 32ml, water glass 18ml, and collector 52ml to obtain the roughing concentrate and roughing tailings, and the roughing concentrate continues to be selected for the first stage.

[0087] The rougher tailings are ground, and the particle size reaches -200 mesh, accounting for more than 96.8%.

[0088] The tailings after grinding are subjected to the first-stage scavenging, adding 9ml of water glass and 21ml of c...

Embodiment 3

[0116] In the present embodiment, the technological method of improving rare earth recovery rate and fluorite grade in the tailings comprises the following steps:

[0117] 1) Mixed flotation

[0118] Such as figure 1 Shown is the flow chart of the mixed flotation process. In the mixed flotation process, the pH is 10-11 and the temperature is 28°C. Mixed flotation includes a rough selection, a second sweep and four refinements.

[0119] Roughly select 250g of Baiyan Obo tailings with a REO grade of 7.00% or more and a fluorite grade of 11.5% or more, and add Na 2 CO 3 29ml, water glass 21ml, and collector 49ml to obtain the rougher concentrate and rougher tailings, and the rougher concentrate continues to be selected for the first stage.

[0120] The rougher tailings are ground, and the particle size reaches -200 mesh, accounting for more than 96.8%.

[0121] The tailings after grinding are subjected to the first-stage scavenging, adding 12ml of water glass and 18ml of col...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com