High-temperature lasting test device and method for environment corrosion

A long-lasting test, environmental corrosion technology, used in measuring devices, weather resistance/light resistance/corrosion resistance, and application of stable tension/pressure to test the strength of materials, etc. The effect of simple structure, simple method and easy operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments, so as to describe the technical solution of the present invention in detail.

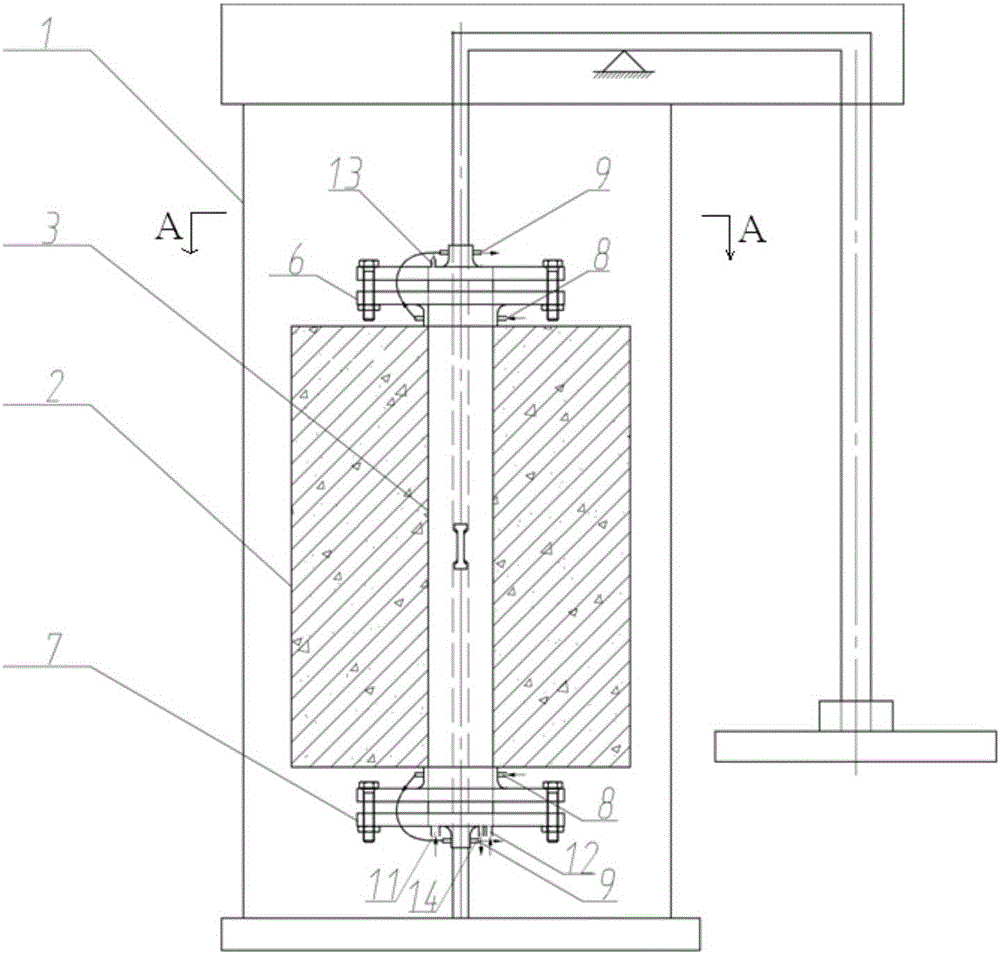

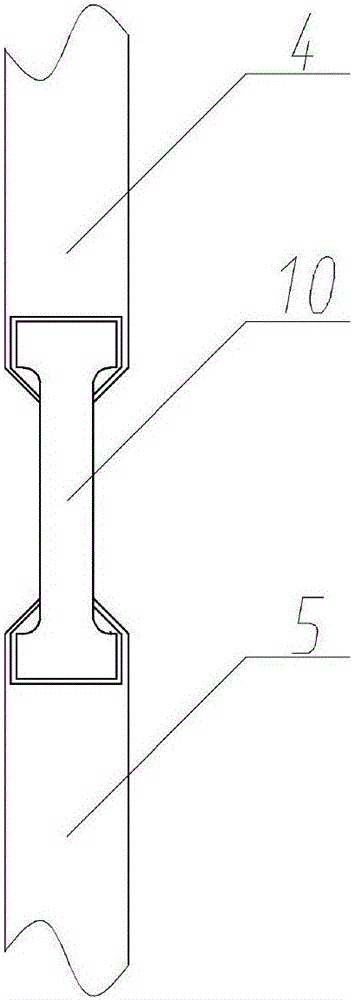

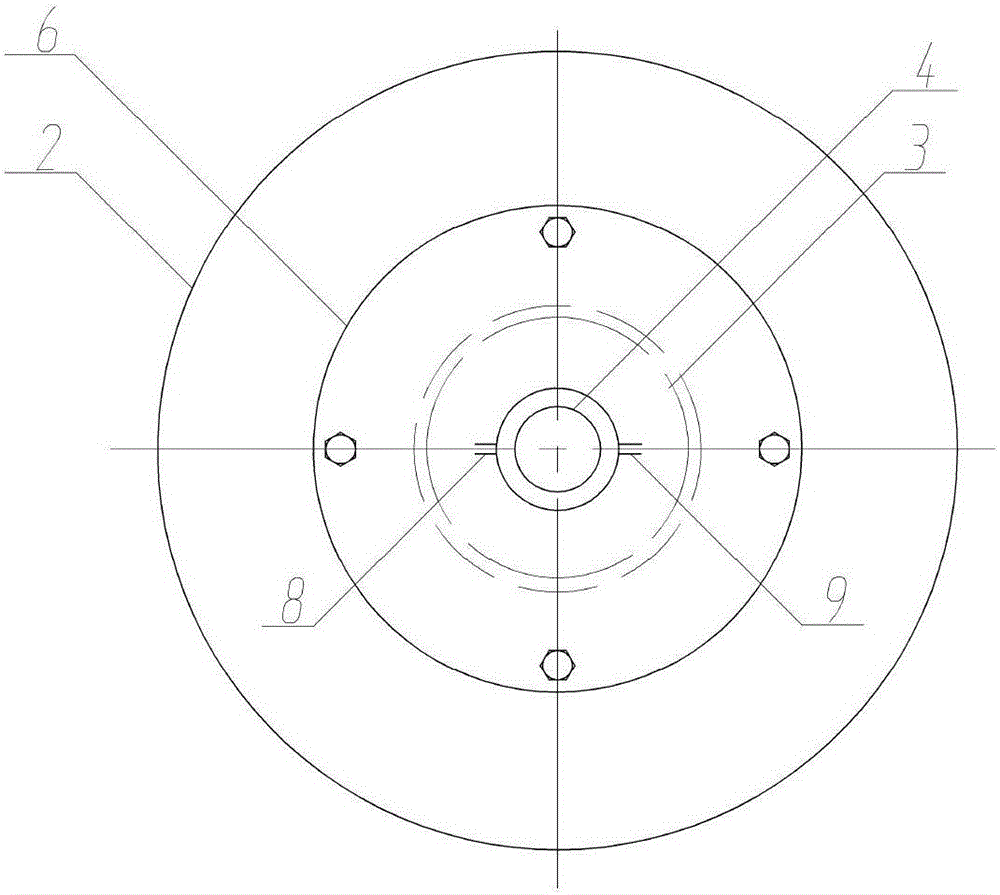

[0046] see Figure 1-Figure 5 , the main frame of the high-temperature endurance testing machine in the present invention is an existing device. The high-temperature durability test device for environmental corrosion of the present invention is used to realize the high-temperature durability performance test of metal materials in a corrosive atmosphere or an oxidative atmosphere; it includes a quartz sealing system, a gas distribution system and Residual gas purification device.

[0047] see figure 1 , figure 2 with image 3 , the main engine of the high-temperature endurance testing machine provides force and heat source for the high-temperature endurance performance test of metal materials, including the frame, power system, transmission system, electrical syste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com