Manufacturing method of degradable pot for growing seedlings

A production method and technology for raising seedlings, which are applied in application, cultivation, agriculture and other directions, can solve the problems of sliding span collapse of garbage dumps in sanitary landfills, affecting landfill operations, and high moisture content of sludge, and achieving low cost and high production efficiency. Simple operation and low investment effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

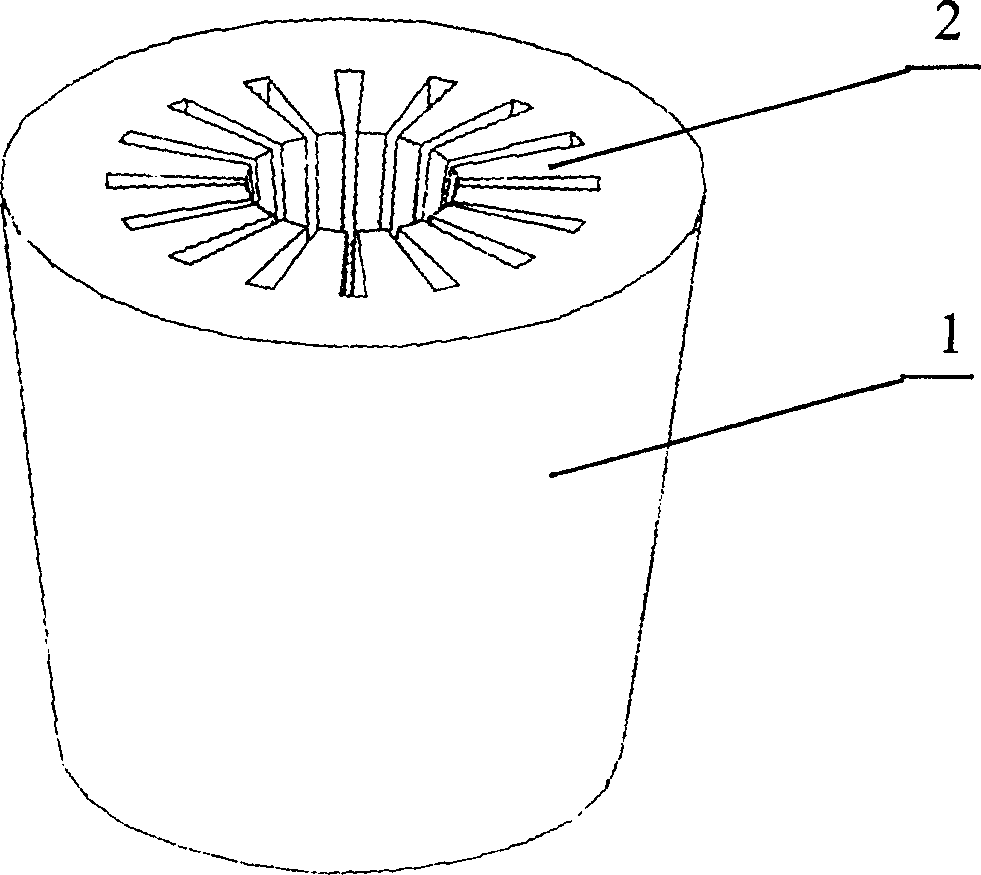

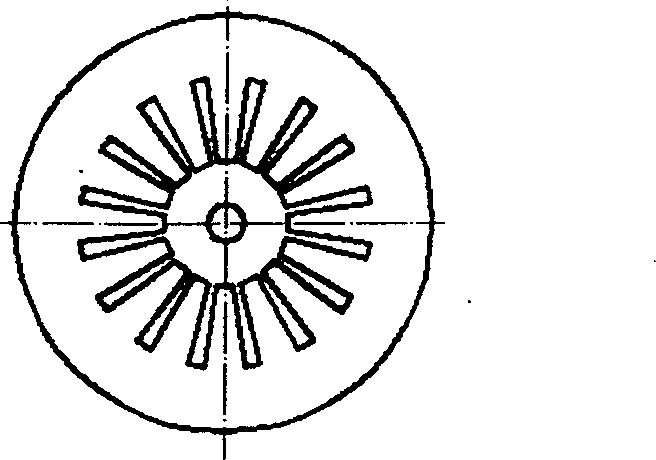

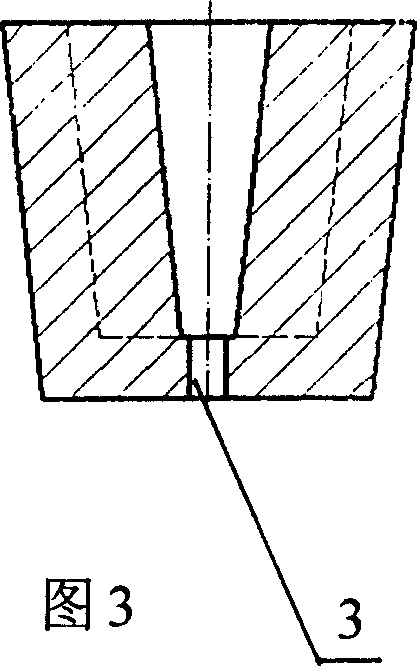

[0033] A method for making a degradable seedling pot, comprising the following steps:

[0034] (1) Mix the sludge compost product and clay evenly; the weight percentage example of sludge compost product mixed with clay is: sludge compost product 90%, clay 10%;

[0035] (2) The mixed material is pressed into shape through a mould;

[0036] (3) drying (generally natural drying), that is, the product of the seedling pot is obtained.

[0037] The sludge composting product is obtained by mixing sludge with a water conditioner and undergoing aerobic fermentation. with existing technology.

[0038] The moisture regulator can be pulverized stalks (for example: wheat straw, rice straw, corn stalk, rape stalk, reed, rattan, bamboo, herbs or other cellulose-containing materials), fly ash or / and saw sawdust. The mixing weight ratio of sludge and moisture conditioner is sludge: moisture conditioner is 1:1.2.

[0039] The aerobic fermentation process goes through three stages: medium t...

Embodiment 2

[0042] A method for making a degradable seedling pot, comprising the following steps:

[0043] (1) mix the sludge composting product and clay evenly; the weight percentage example of sludge composting product and clay mixing is: sludge composting product 75%, clay 25%;

[0044] (2) The mixed material is pressed into shape through a mould;

[0045] (3) drying (generally natural drying), that is, the product of the seedling pot is obtained.

[0046] Others are the same as in Example 1, omitted.

Embodiment 3

[0048] A method for making a degradable seedling pot, comprising the following steps:

[0049] (1) Mix the sludge compost product and clay evenly; the weight percentage example of sludge compost product mixed with clay is: sludge compost product 80%, clay 20%;

[0050] (2) The mixed material is pressed into shape through a mould;

[0051] (3) drying (generally natural drying), that is, the product of the seedling pot is obtained.

[0052] Others are the same as in Example 1, omitted.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Outer diameter | aaaaa | aaaaa |

| The inside diameter of | aaaaa | aaaaa |

| Wall thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com