Prefabricated steel fiber sludge-made ceramisite concrete wall based on T-shaped groove connection and construction method of prefabricated steel fiber sludge-made ceramisite concrete wall

A technology for making ceramsite and concrete walls from sludge, which is applied in the processing of walls, building materials, building components, etc. It can solve the problem of lack of multiple fortification and anti-seismic mechanisms in structural systems, difficulty in meeting structural ductility design requirements, energy and raw material consumption Large and other problems, to achieve the effect of solving high prefabrication precision requirements, excellent ductility design, and fast construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

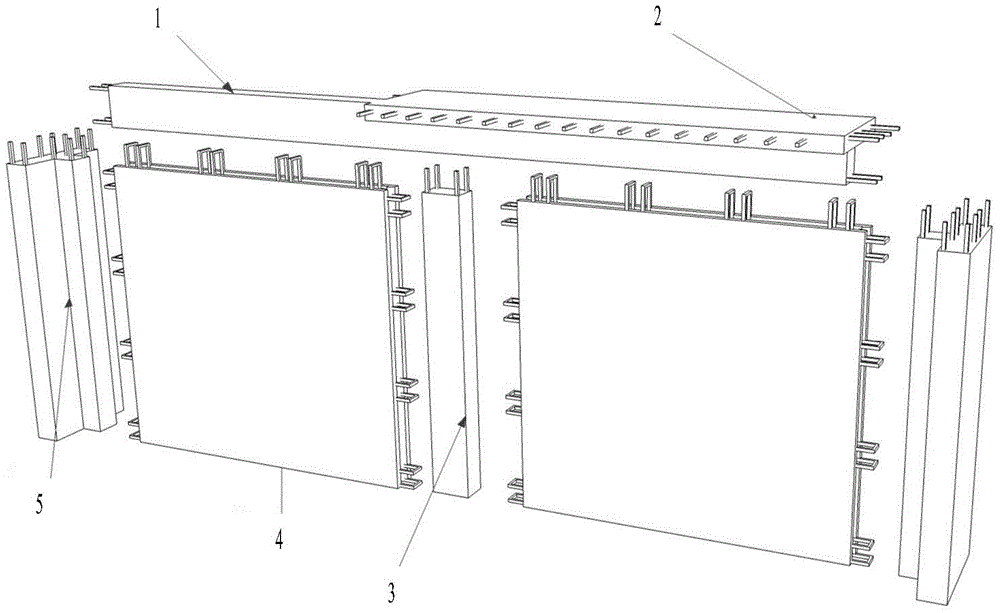

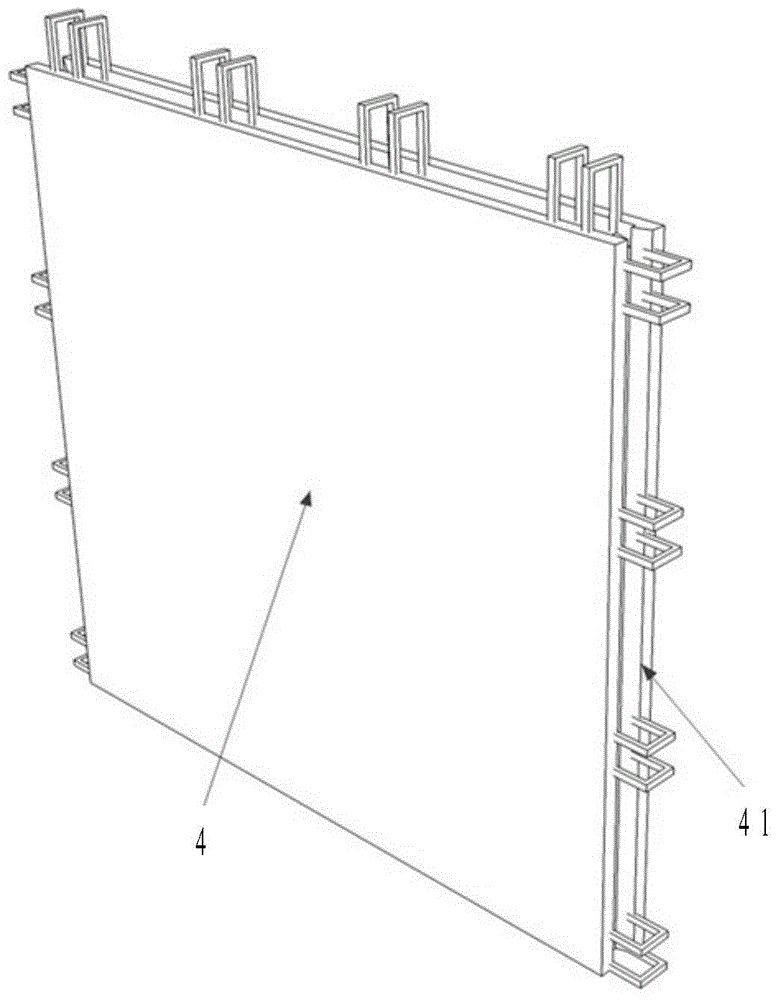

[0031] Such as figure 1 and figure 2 Shown, a kind of prefabricated steel fiber sludge system ceramsite concrete wall based on T-shaped slot connection of the present invention comprises:

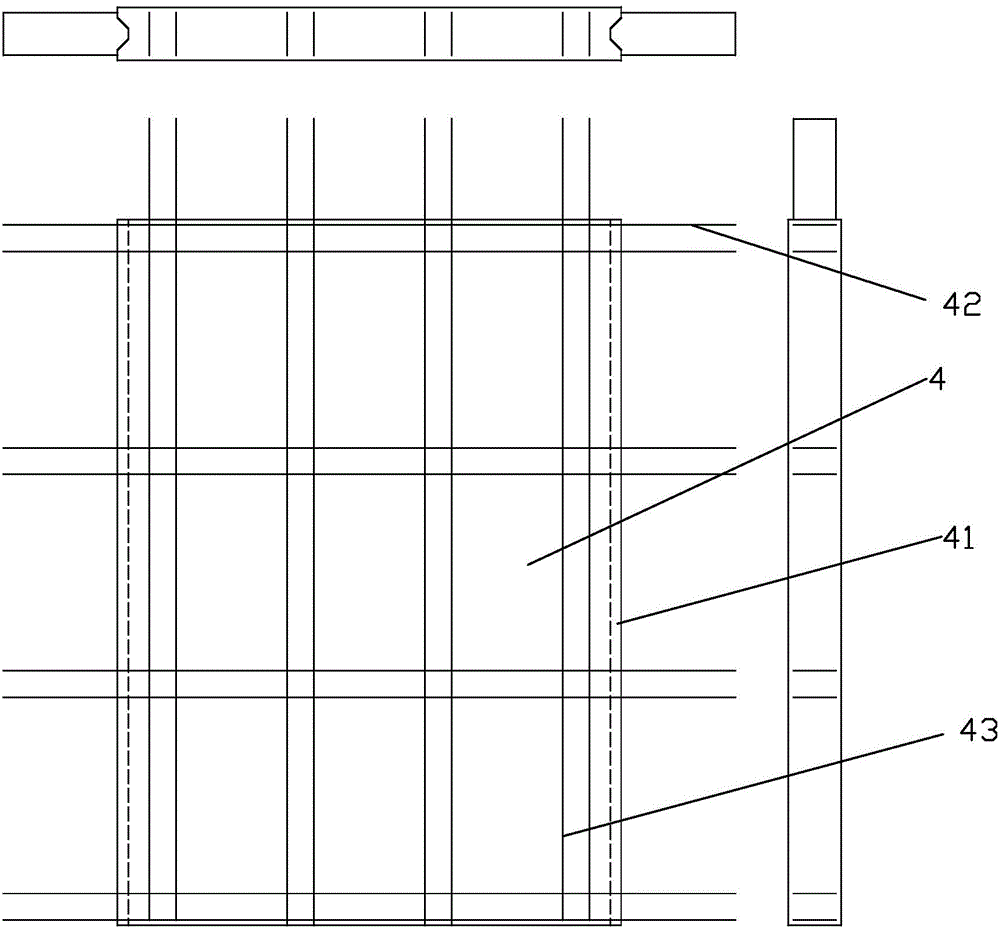

[0032] The bottom of the prefabricated wall panel 4 is connected to the wall foundation by sitting grout. The mortar needs to be laid with a uniform thickness. After the wall panels are installed, the mortar joints should be filled tightly, and the filled mortar joints should have a smooth and smooth surface. The two sides are T-shaped groove structures 41, with built-in horizontal and vertical steel bars; horizontal steel bars 42 and vertical steel bars 43 are in the form of double bars in the left and right directions and front and rear directions of the prefabricated wall panel 4, which are optimized into a "well" shape ,Such as figure 2 and image 3...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com