Environment-friendly assembled type ecological house and construction method thereof

A prefabricated and ecological technology, applied in the direction of building structure, construction, building materials, etc., can solve the problems of backward residential construction technology, low level of new technology application, low labor production efficiency, etc., to achieve fast construction speed and ensure stability And the effect of high precision and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The implementation of the present invention will be described in detail below in conjunction with the drawings and examples.

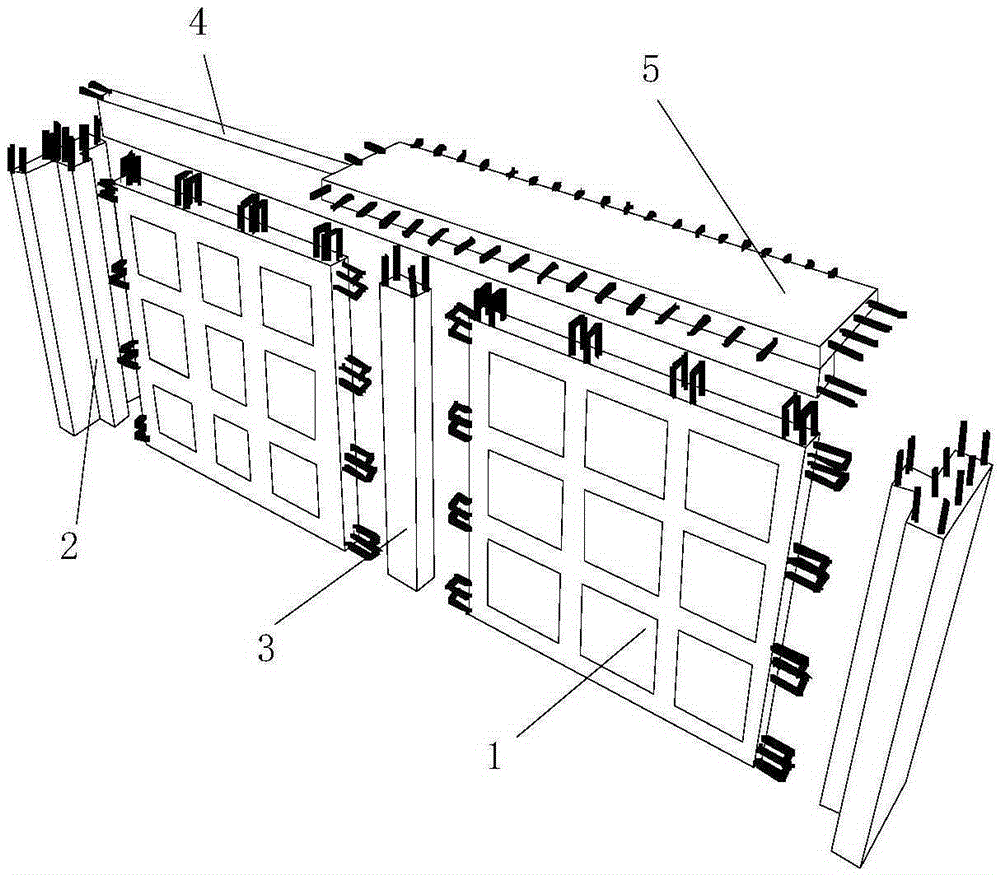

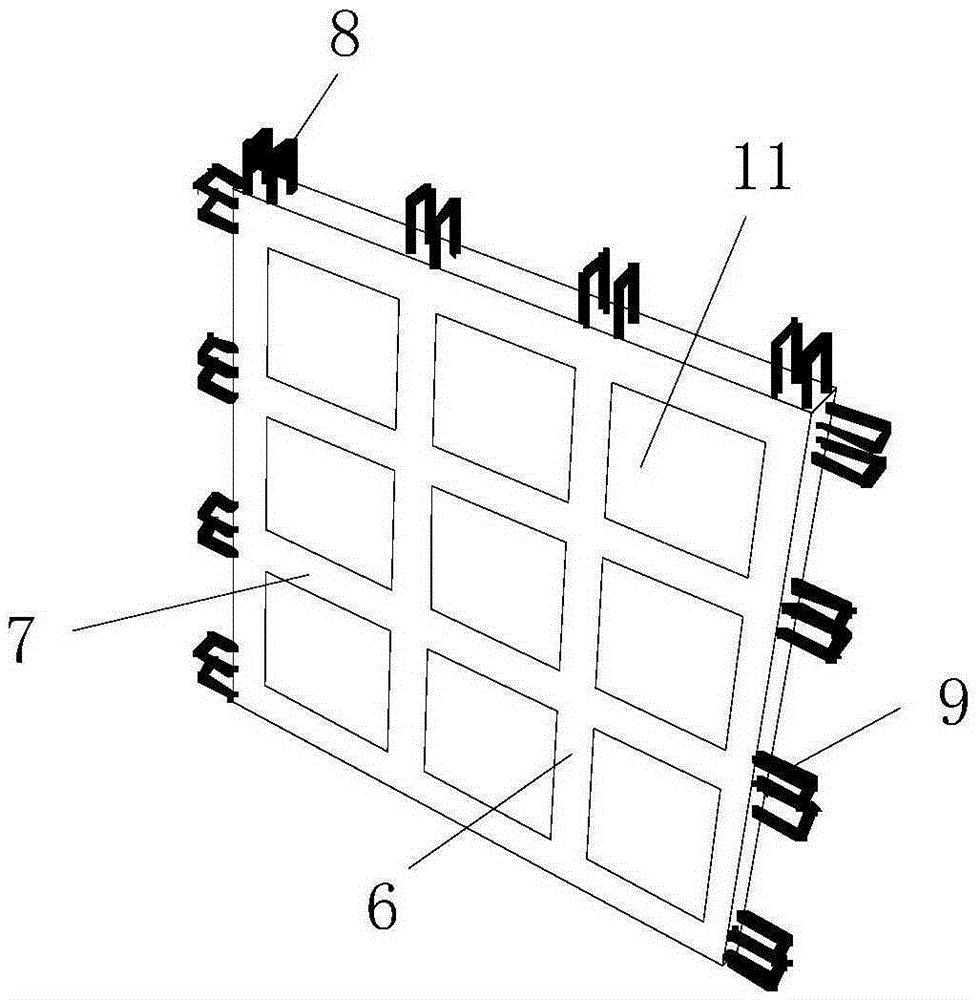

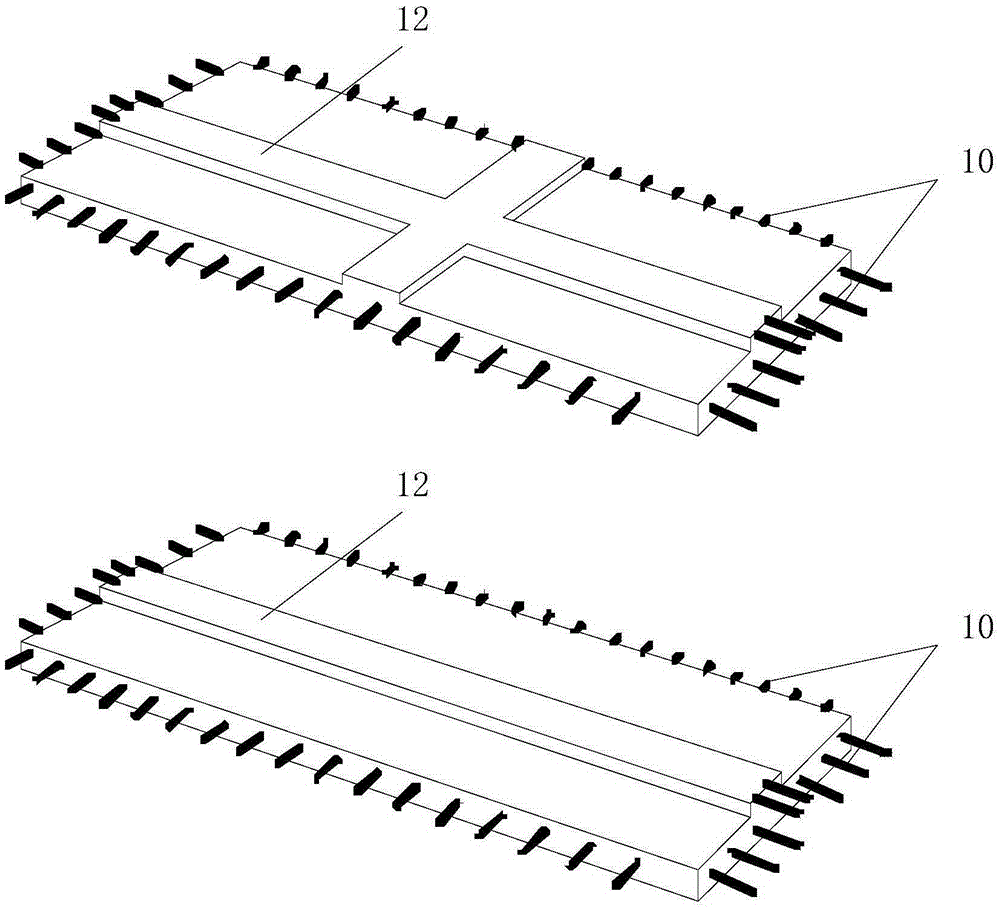

[0036] A green prefabricated ecological dwelling of the present invention comprises a wall and a roof, wherein the wall is as figure 1As shown, including the mortar at the bottom of the wallboard, a prefabricated ecological composite wallboard 1 is installed on the mortar at the bottom of the wallboard. The longitudinal reinforcement of the cast-in-place concealed beam 4 is nested, and the longitudinal reinforcement of the cast-in-place concealed beam 4 is nested with the horizontal connection reinforcement of the prefabricated laminated floor 5 at the same time, so as to realize the connection between the prefabricated ecological composite wall panel 1 and the prefabricated laminated floor 5. The cast-in-place vertical edge components 2, cast-in-place connecting columns 3 and cast-in-place concealed beams 4 are externally poured with concrete. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com