Pasturage combine harvesting disintergrator

A pulverizer and hammer pulverizer technology, applied in harvesters, loaders, crop processors, etc., can solve the problems of easy fire of haystacks, unsafe production, and high labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

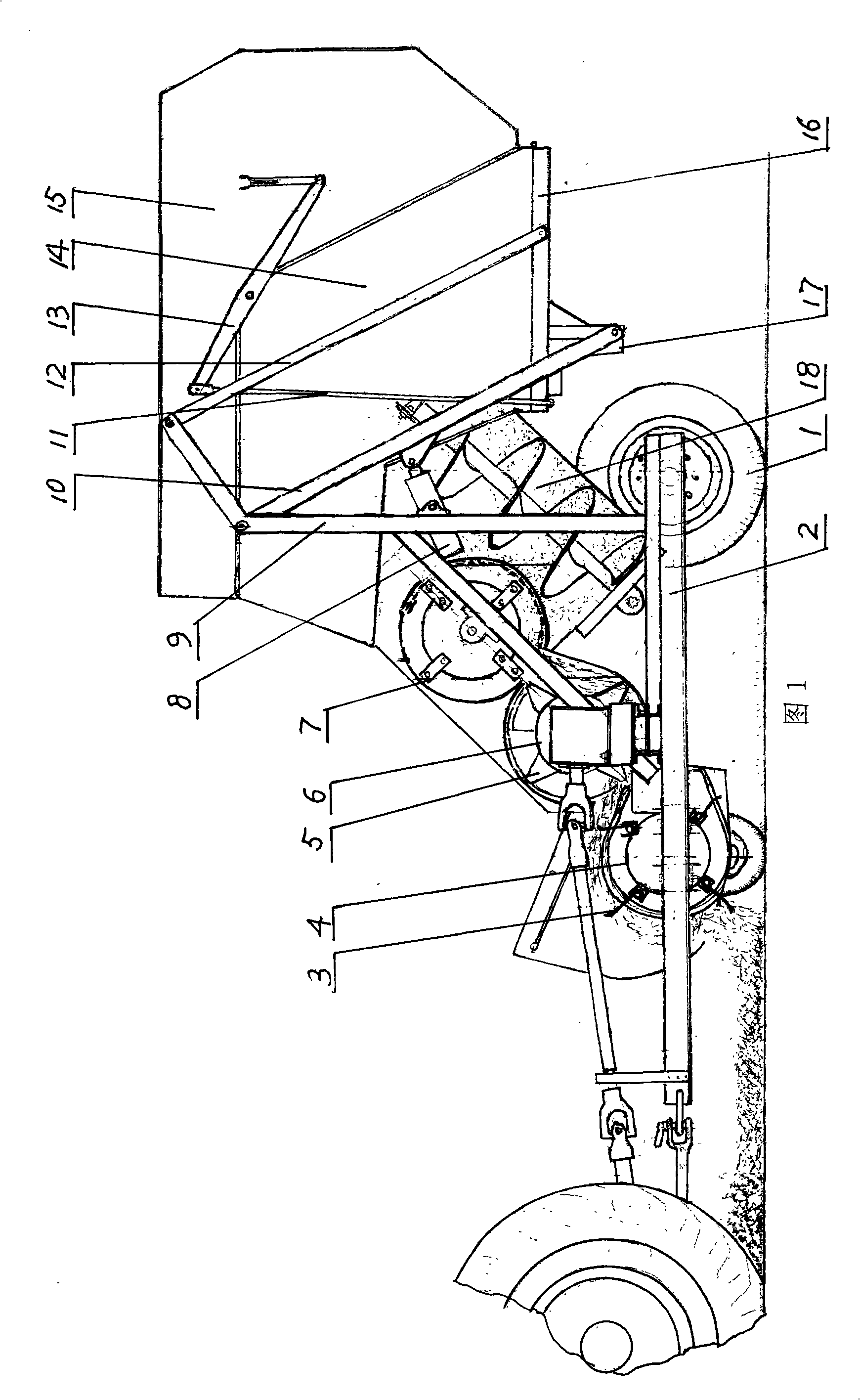

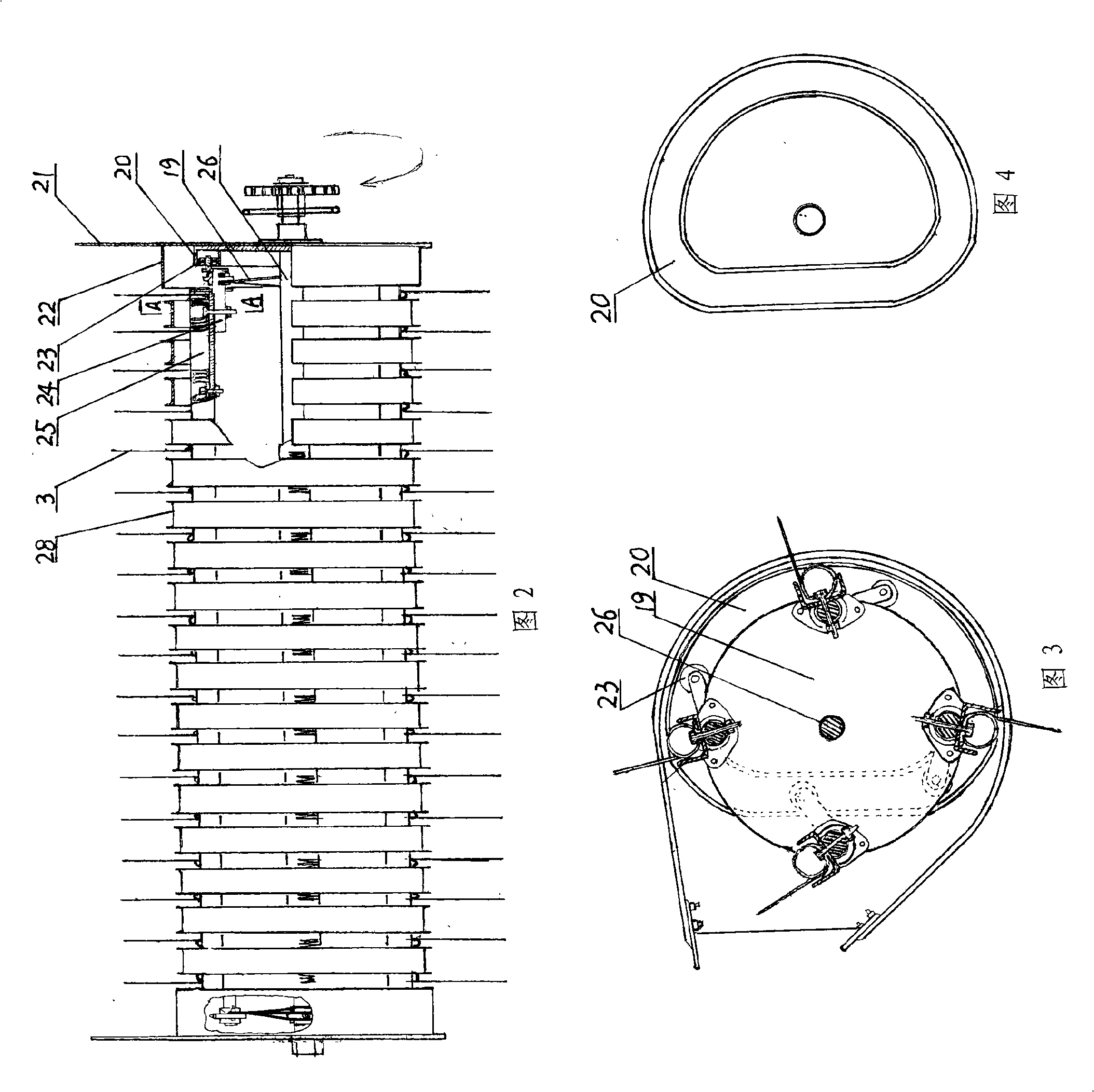

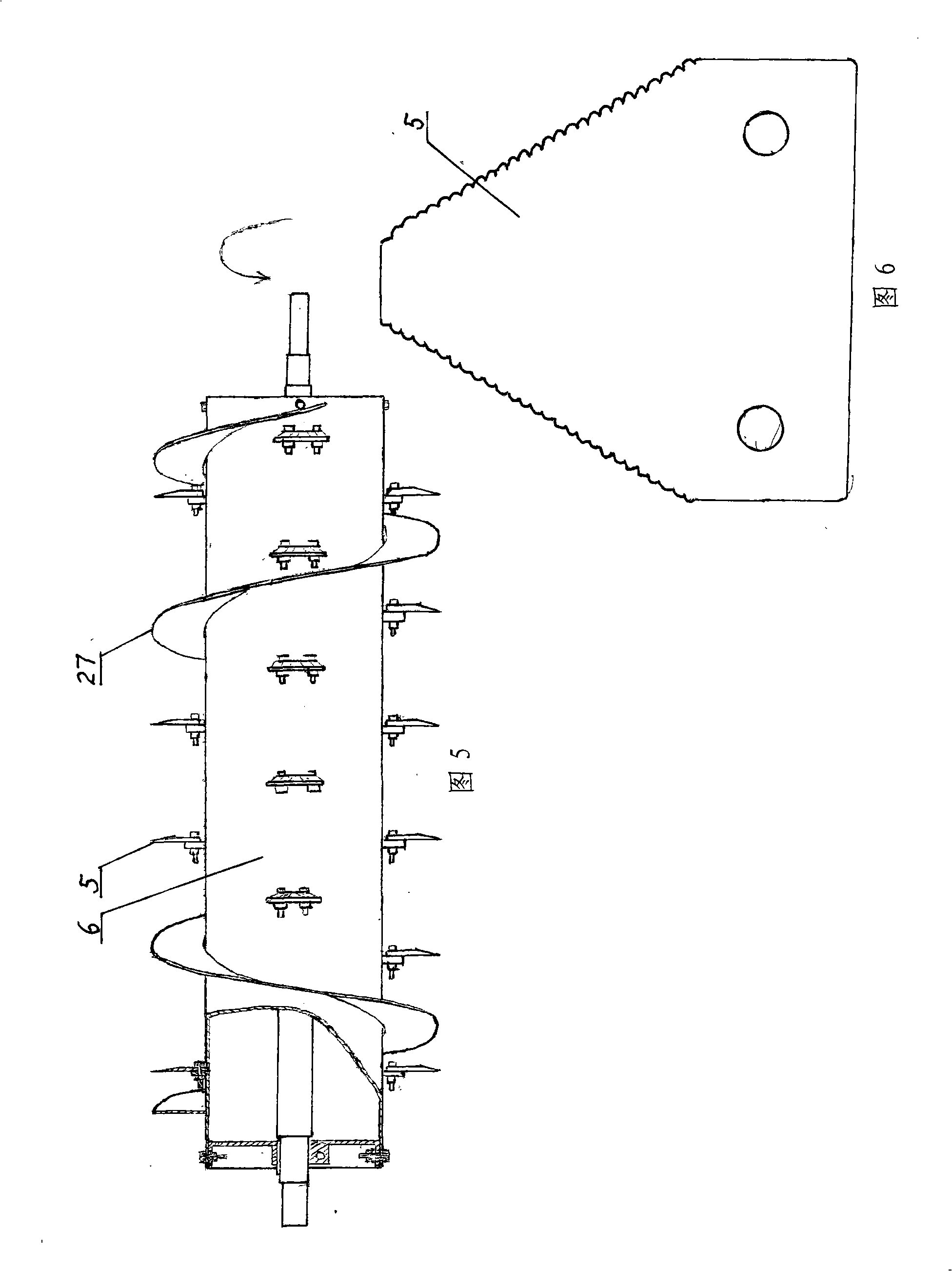

[0015] A forage combined harvesting crusher, as shown in Figure 1, Figure 2, Figure 3, and Figure 4, includes a hammer mill 7 mounted on a frame 2 with wheels 1 driven by a tractor, and a hammer mill 7 on the frame 2 The front part is equipped with a pickup 4 with spring teeth 3 uniformly distributed on the roller surface. The pickup 4 is equipped with a spindle 26 on symmetrical side walls through bearings, and is evenly distributed on the webs 19 fixed on both sides of the spindle 26 A symmetrical shaft sleeve is provided, and a spring tooth base 25 with a turning shaft 24 at one end and a rotating shaft at the other end is respectively installed through the shaft sleeves. The spring teeth base 25 is fixed by bolts to the uniformly distributed spring teeth 3, the spring teeth The seat 25 is made of channel steel. The crank arm fixed to the end of the crank shaft 24 has a roller 23 installed at its end, and the roller 23 cooperates with the closed curved track 20 provided on the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com