Method for preparing iron silicon soft magnetic alloy powder core

A technology of iron-silicon alloy and soft magnetic alloy, which is applied in the direction of magnetic materials, magnetic objects, inorganic materials, etc., can solve the problems of unsatisfactory comprehensive performance of iron-silicon alloy powder core, hard-to-break iron-silicon alloy, high price, etc., and achieve Good DC superposition characteristics, high frequency and low loss characteristics, and the effect of meeting performance requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

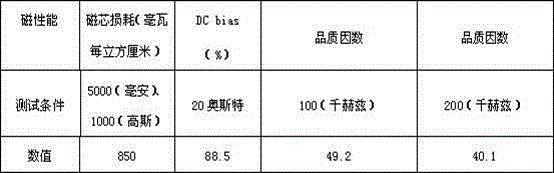

Embodiment 1

[0020] Embodiment 1 of the present invention comprises the following steps:

[0021] 1. Use a vacuum quick-setting casting furnace to melt and refine industrial pure iron, crystalline silicon and ferrophosphorus, and produce iron-silicon containing Si 6.5%, P 0.1% and the rest Fe (weight percentage) through quick-setting and rapid quenching Alloy flakes, and then use mechanical crushing method to grind into quick-quenching iron-silicon alloy powder through ring hammer mill;

[0022] 2. Mix the prepared quick-quenched iron-silicon alloy powder with the iron-silicon alloy powder produced by the atomization method according to the ratio of 1:1, and then prepare composite iron-silicon alloy powder by sieving, and its particle size ratio is ≥250 mesh powder Accounted for 65%, 100 ~ 250 mesh powder accounted for 35%;

[0023] 3. Heat treatment of composite iron-silicon alloy powder: put the composite iron-silicon alloy powder into a protective atmosphere furnace, pass in hydrogen g...

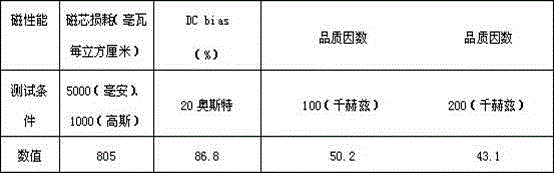

Embodiment 2

[0032] Embodiment 2 of the present invention comprises the following steps:

[0033] 1. Industrial pure iron, crystalline silicon and ferrophosphorus are melted and refined in a vacuum quick-setting casting furnace, and the iron-silicon alloy containing Si 6.0%, P 0.45% and the rest is Fe (weight percentage) is produced through quick-setting and rapid quenching flakes, and then use mechanical crushing method to grind into quick-quenching iron-silicon alloy powder through ring hammer mill;

[0034] 2. Mix the prepared quick-quenched iron-silicon alloy powder with the iron-silicon alloy powder produced by the atomization method according to the ratio of 1:1, and then prepare composite iron-silicon alloy powder by sieving, and its particle size ratio is ≥250 mesh powder Accounted for 60%, 100 ~ 250 mesh powder accounted for 40%;

[0035] 3. Heat treatment of the composite iron-silicon alloy powder: put the composite alloy powder into a protective atmosphere furnace, pass in hydr...

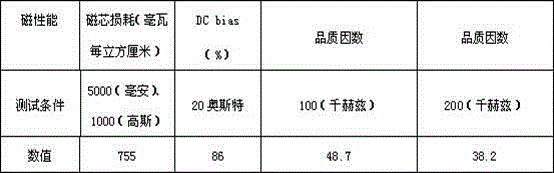

Embodiment 3

[0044] Embodiment 3 of the present invention comprises the following steps:

[0045] 1. Industrial pure iron, crystalline silicon and ferrophosphorus are melted and refined in a vacuum quick-setting casting furnace, and the iron-silicon alloy containing Si 6.8%, P 0.3% and the rest is Fe (weight percentage) is produced through quick-setting and rapid quenching flakes, and then use mechanical crushing method to grind into quick-quenching iron-silicon alloy powder through ring hammer mill;

[0046] 2. Mix the prepared quick-quenching iron-silicon alloy powder with the iron-silicon alloy powder produced by the atomization method according to the ratio of 1:1, and then prepare composite iron-silicon alloy powder through sieving, and its particle size ratio is ≥250 mesh powder Accounted for 70%, 100 ~ 250 mesh powder accounted for 30%;

[0047] 3. Heat treatment of composite iron-silicon alloy powder: put the composite alloy powder into a protective atmosphere furnace, pass in hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com