Rotation-revolution combined down-hole hammer and construction method thereof

A combined down-the-hole hammer and construction method technology, which is applied to drilling equipment and methods, earthwork drilling, percussion drilling, etc., can solve problems such as difficult manufacturing, uneven wear, and inconvenient maintenance and repair, and achieve improved Working efficiency and service life, work and wear balance, and the effect of improving drilling efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0056] Embodiment 1: A self-revolving combined down-the-hole hammer:

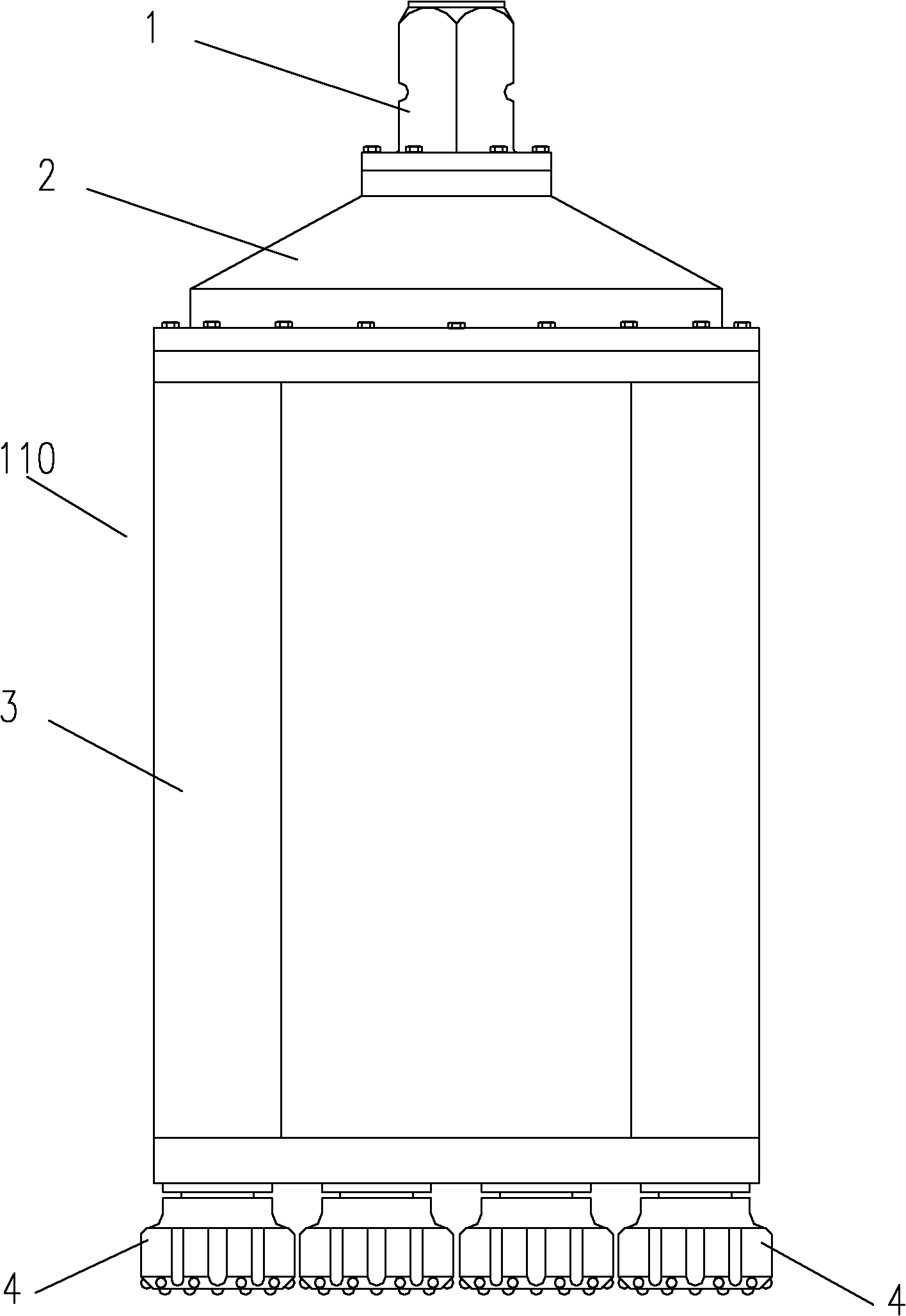

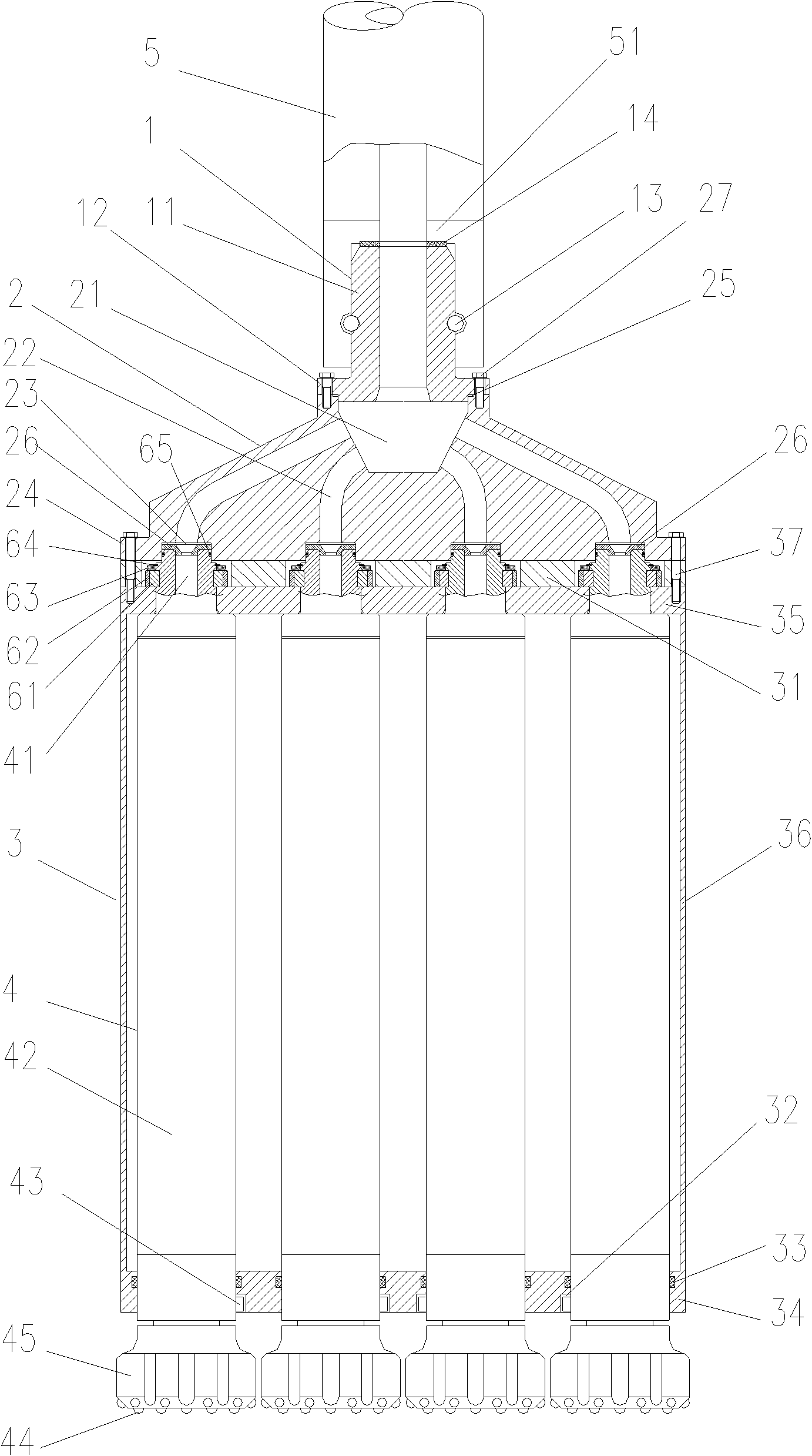

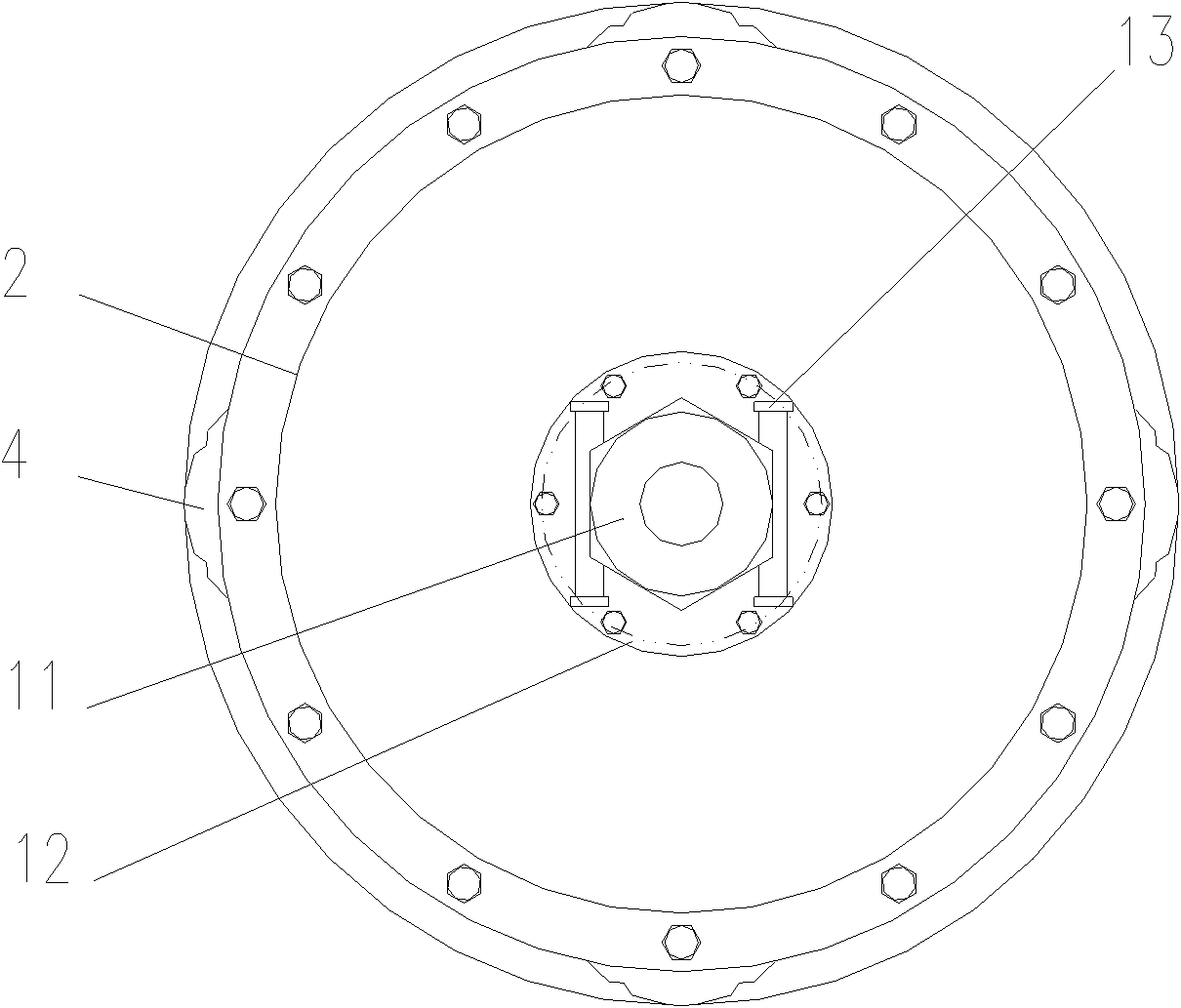

[0057] refer to figure 1 , figure 2 , image 3 , Figure 4 , Figure 15 and Figure 16 .

[0058] A self-revolving combined down-the-hole hammer 110 includes: a coupler 1 , an air distribution device 2 , a support body 3 and several small-diameter impactors 4 .

[0059] The above-mentioned coupling 1 is mainly composed of a joint body 11, a flange 12, a pin shaft 13, and a gasket 14; the gas distribution device 2 is mainly composed of a gas collection chamber 21, a gas distribution channel 22, a transition air hole 23, and a flange 24; The bracket body 3 is composed of a transition plate 31 with holes, a bottom plate 34 with positioning holes and key grooves 32 and a dust-proof ring 33, an upper plate 35 with positioning holes, and a housing 36; the impactor 4 is mainly composed of joints 41, containing The impactor body 42 of the piston 410, the positioning key 43 and the impact drill bit 45 with ...

Embodiment 2

[0064] Embodiment 2: A construction method using a self-revolving combined down-the-hole hammer 110 .

[0065] refer to Figure 5 , Figure 6 , Figure 7 , Figure 8 , Figure 9 , Figure 10 , Figure 11 and Figure 12 . The construction method using self-revolving combined down-the-hole hammer 110 has the following steps:

[0066] ① The drilling rig 330 with the power head 7, the air supply system 8, and the hollow cylindrical drill pipe 5 walks to the construction position, and inserts the self-rotating combined down-the-hole hammer 110 and the drill pipe 5 with the help of two pin shafts 13 and gaskets 14. fixed; (see Figure 5 , Figure 7 )

[0067] ② Start the power head 7 of the drilling rig 330 to drive the drill pipe 5 and the self-revolving combined DTH hammer 110 to rotate clockwise. After aligning the hole position, start the air supply system 8 to provide compressed air to drive the self-revolving combined DTH hammer 110 Each impactor 4 moves; the power...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com