Composite anti-seepage structure for red mud tailing ponds

A composite anti-seepage and tailings pond technology is applied in the field of composite anti-seepage structures of red mud tailings ponds, which can solve the threats to the safety of residents' lives and property and the surrounding environment, leakage of red mud and red mud attached liquid, and easy anti-seepage cloth. Damaged and other problems, to avoid the settlement of the base layer, the reliability of the joint is high, and the effect of reducing peeling damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

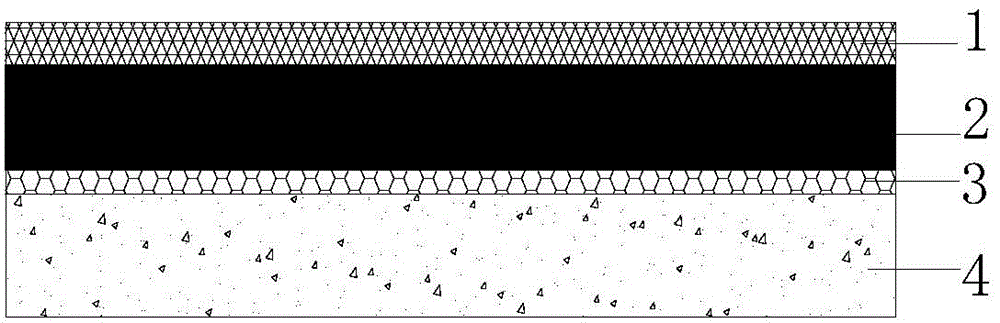

[0016] The composite anti-seepage structure of the red mud tailings pond in this embodiment includes the anti-seepage layer 2 arranged on the slope, the flexible protective layer 1 arranged on the anti-seepage layer 2 and the rigid protective layer arranged under the anti-seepage layer 2 4. An isolation layer 3 is also provided between the rigid protective layer 4 and the anti-seepage layer 2. The isolation layer 3 is formed by mixing wheat straw or straw with clay. The material of the anti-seepage layer 2 includes the following group by weight: Divide: 25 parts of polycarbonate, 15 parts of polytetrafluoroethylene, 8 parts of polybutylene terephthalate, 12 parts of fly ash, 6 parts of hammer milled glass fiber, 3 parts of graft copolymerized acrylic acid derivatives, 3 parts Antioxidant, 2 parts UV absorber, 2 parts antiaging agent.

[0017] In this embodiment, the flexible protective layer 1 is a flexible steel wire mesh.

[0018] In this embodiment, the antioxidant is dici...

Embodiment 2

[0024] The composite anti-seepage structure of the red mud tailings pond in this embodiment includes the anti-seepage layer 2 arranged on the slope, the flexible protective layer 1 arranged on the anti-seepage layer 2 and the rigid protective layer arranged under the anti-seepage layer 2 4. An isolation layer 3 is also provided between the rigid protective layer 4 and the anti-seepage layer 2. The isolation layer 3 is formed by mixing wheat straw or straw with clay. The material of the anti-seepage layer 2 includes the following group by weight: Divide: 20 parts of polycarbonate, 10 parts of polytetrafluoroethylene, 5 parts of polybutylene terephthalate, 10 parts of fly ash, 1 part of hammer milled glass fiber, 1 part of graft copolymerized acrylic acid derivatives, 1 part Antioxidant, 0.5 part UV absorber, 1 part antiaging agent.

[0025] In this embodiment, flexible galvanized steel wire mesh.

[0026] In this embodiment, the antioxidant is distearoyl thiodipropionate. In t...

Embodiment 3

[0032]The composite anti-seepage structure of the red mud tailings pond in this embodiment includes the anti-seepage layer 2 arranged on the slope, the flexible protective layer 1 arranged on the anti-seepage layer 2 and the rigid protective layer arranged under the anti-seepage layer 2 4. An isolation layer 3 is also provided between the rigid protective layer 4 and the anti-seepage layer 2. The isolation layer 3 is formed by mixing wheat straw or straw with clay. The material of the anti-seepage layer 2 includes the following group by weight: Divide: 30 parts of polycarbonate, 20 parts of polytetrafluoroethylene, 12 parts of polybutylene terephthalate, 15 parts of fly ash, 10 parts of hammer milled glass fiber, 5 parts of graft copolymerized acrylic acid derivatives, 5 parts Antioxidant, 3 parts of UV absorber, 3 parts of antioxidant;

[0033] In this embodiment, the flexible protective layer 1 is a high-strength polyester fiber flexible net.

[0034] In the present embodim...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com