Manufacturing method of high-green-strength atomized copper powder

A technology of atomizing copper powder and green strength, which is applied in the field of metal powder materials and powder metallurgy, can solve the problems of surrounding ecological environment pollution, etc., and achieve the effects of improving green strength, increasing surface tension, and increasing viscosity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

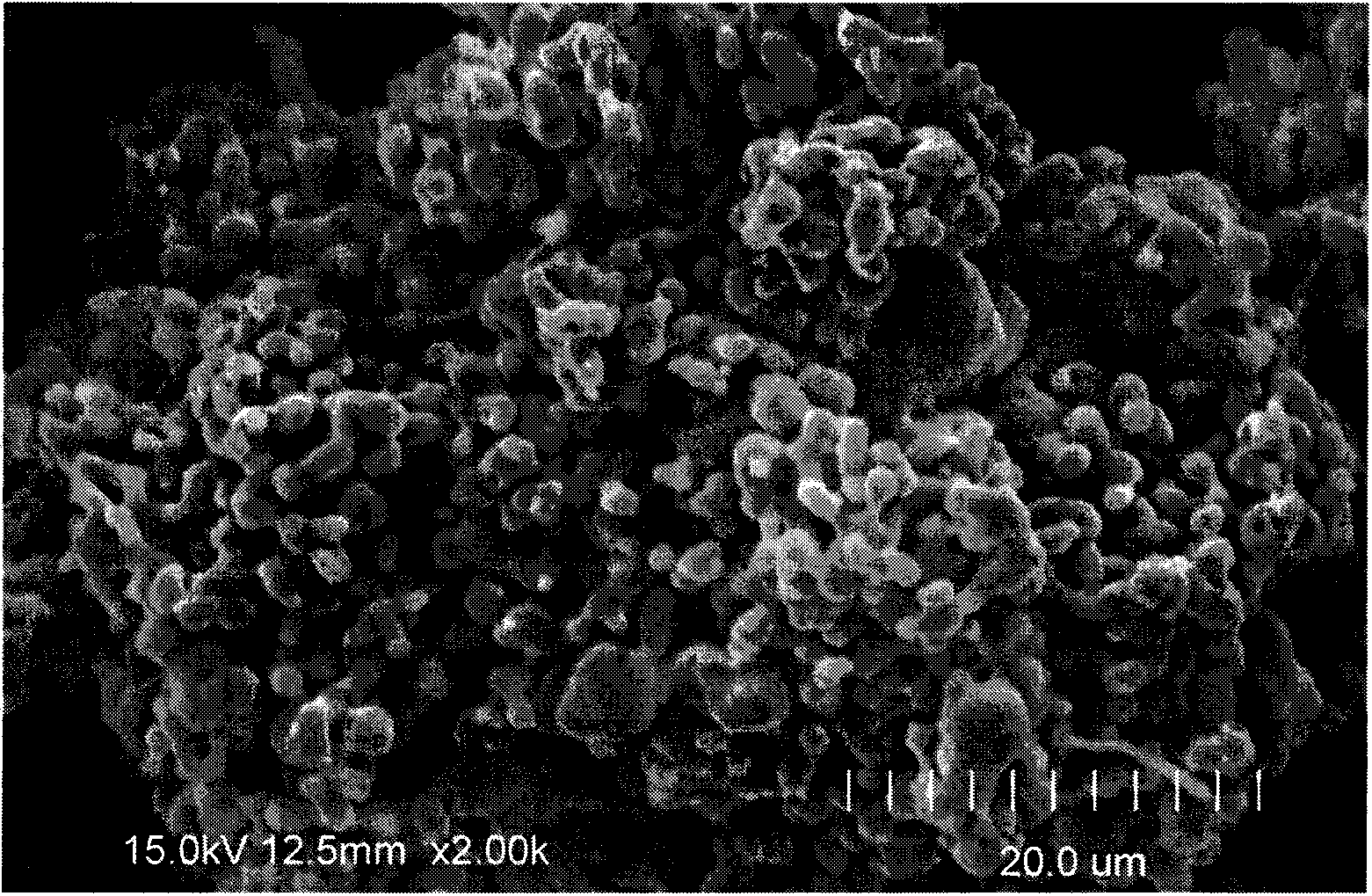

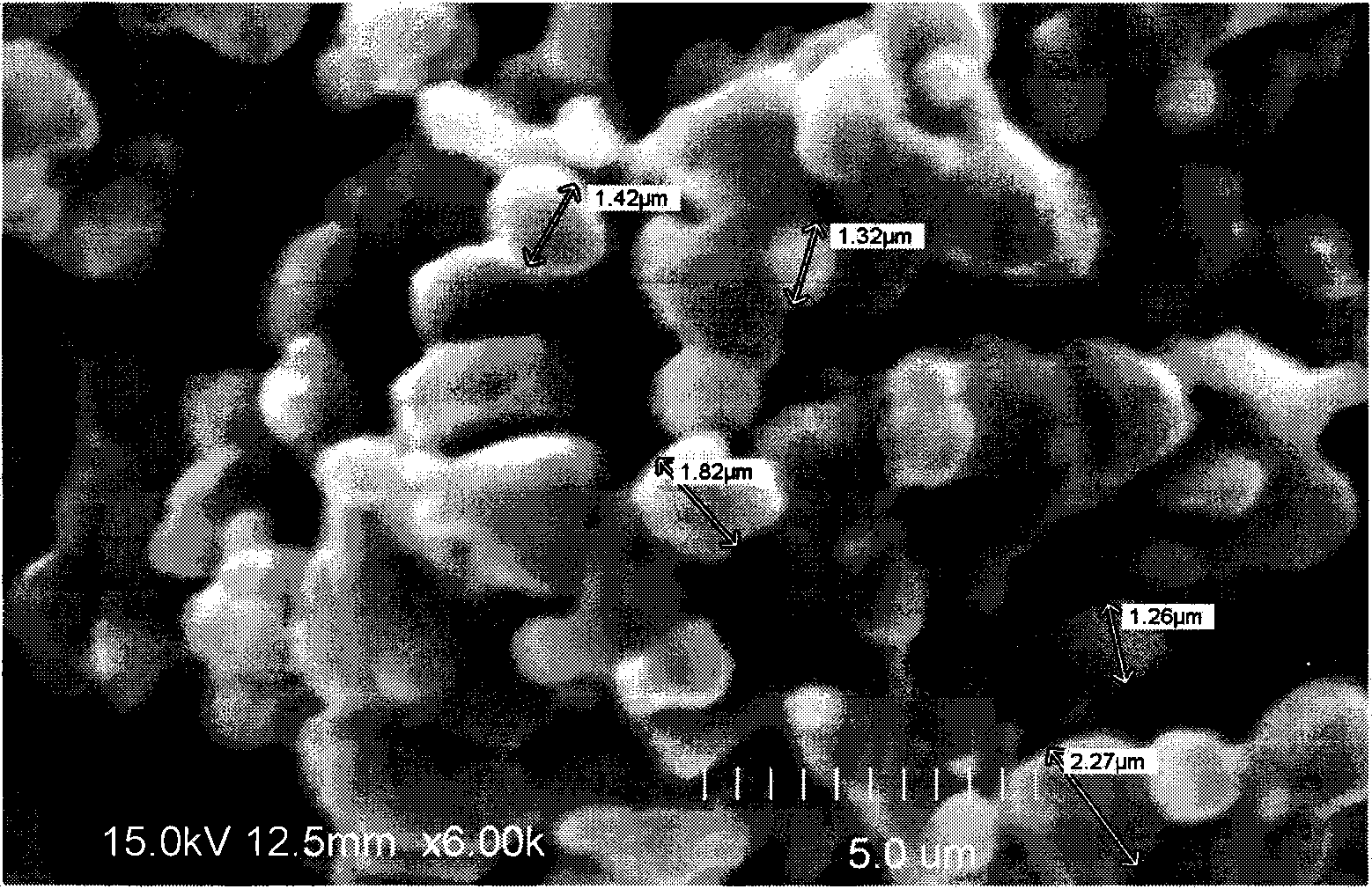

Image

Examples

Embodiment 1

[0028] A method for making atomized copper powder with high green strength, specifically comprising the following steps:

[0029] 1. Smelting treatment: put the solid pure copper raw material in a melting furnace to melt to obtain liquid copper. The temperature of the melting furnace is 1350°C. During the melting process, oxygenation treatment is carried out. The oxygenation treatment is to add oxygen into the furnace to make the melting after oxygenation The oxygen mass percentage content of the copper liquid is 15%, and the oxygen-increasing treatment may be to blow pure oxygen to the molten metal copper in the melting furnace.

[0030] 2. Atomization treatment: When the liquid copper flows out of the furnace, the atomized copper powder is sprayed out using a closed V-shaped nozzle under a high pressure condition of 30PMa.

[0031] 3. Drying treatment: Dry the copper powder obtained by the atomization treatment in step 2. The drying condition is centrifuge dehydration and dr...

Embodiment 2

[0037] A method for making atomized copper powder with high green strength, specifically comprising the following steps:

[0038] 1. Smelting treatment: put the solid pure copper raw material in the melting furnace to melt to obtain liquid copper. The temperature of the melting furnace is 1450°C. During the melting process, oxygenation treatment is carried out. The oxygenation treatment is to add oxygen into the furnace to make the melting after oxygenation The oxygen mass percentage content of the copper liquid is 8%, and the oxygen-increasing treatment may be to blow pure oxygen to the molten metal copper in the melting furnace.

[0039] 2. Atomization treatment: When liquid copper flows out of the furnace, atomized copper powder is sprayed out using a closed V-shaped nozzle under a high pressure condition of 29PMa.

[0040] 3. Drying treatment: drying the copper powder obtained by the atomization treatment in step 2, the drying is vacuum heating treatment, the vacuum heatin...

Embodiment 3

[0044] A method for making atomized copper powder with high green strength, specifically comprising the following steps:

[0045] 1. Smelting treatment: put the solid pure copper raw material in the melting furnace to melt to obtain liquid copper. The temperature of the melting furnace is 1400 ° C. During the melting process, oxygenation treatment is carried out. The oxygenation treatment is to add oxygen into the furnace to make the melting after oxygenation The oxygen mass percentage content of the copper liquid is 10%, and the oxygen-increasing treatment may be to blow pure oxygen to the molten metal copper in the melting furnace.

[0046] 2. Atomization treatment: When the liquid copper flows out of the furnace, the atomized copper powder is sprayed out using a closed V-shaped nozzle under a high pressure condition of 32PMa.

[0047] 3. Drying treatment: drying the copper powder obtained from the atomization treatment in step 2. The drying includes centrifuge dehydration d...

PUM

| Property | Measurement | Unit |

|---|---|---|

| bulk density | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com