Method and apparatus for the manufacture of meat analogue product

A substitute and production line technology, which is applied in the field of textured protein products) and the production of fibrous meat substitutes, can solve the problems of increasing the absorption of humidity, affecting the internal structure and organization of extrudates, and affecting sensitivity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

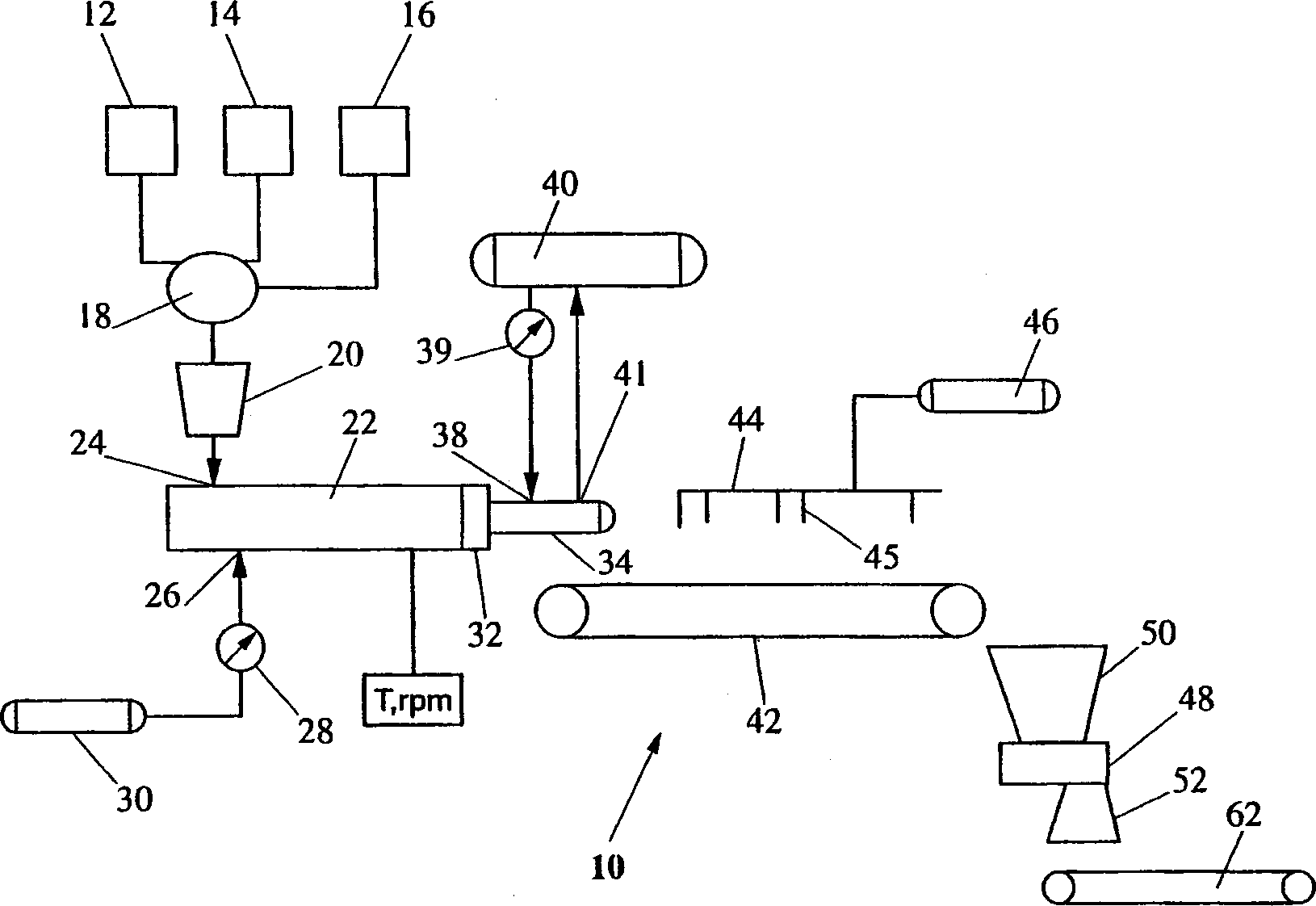

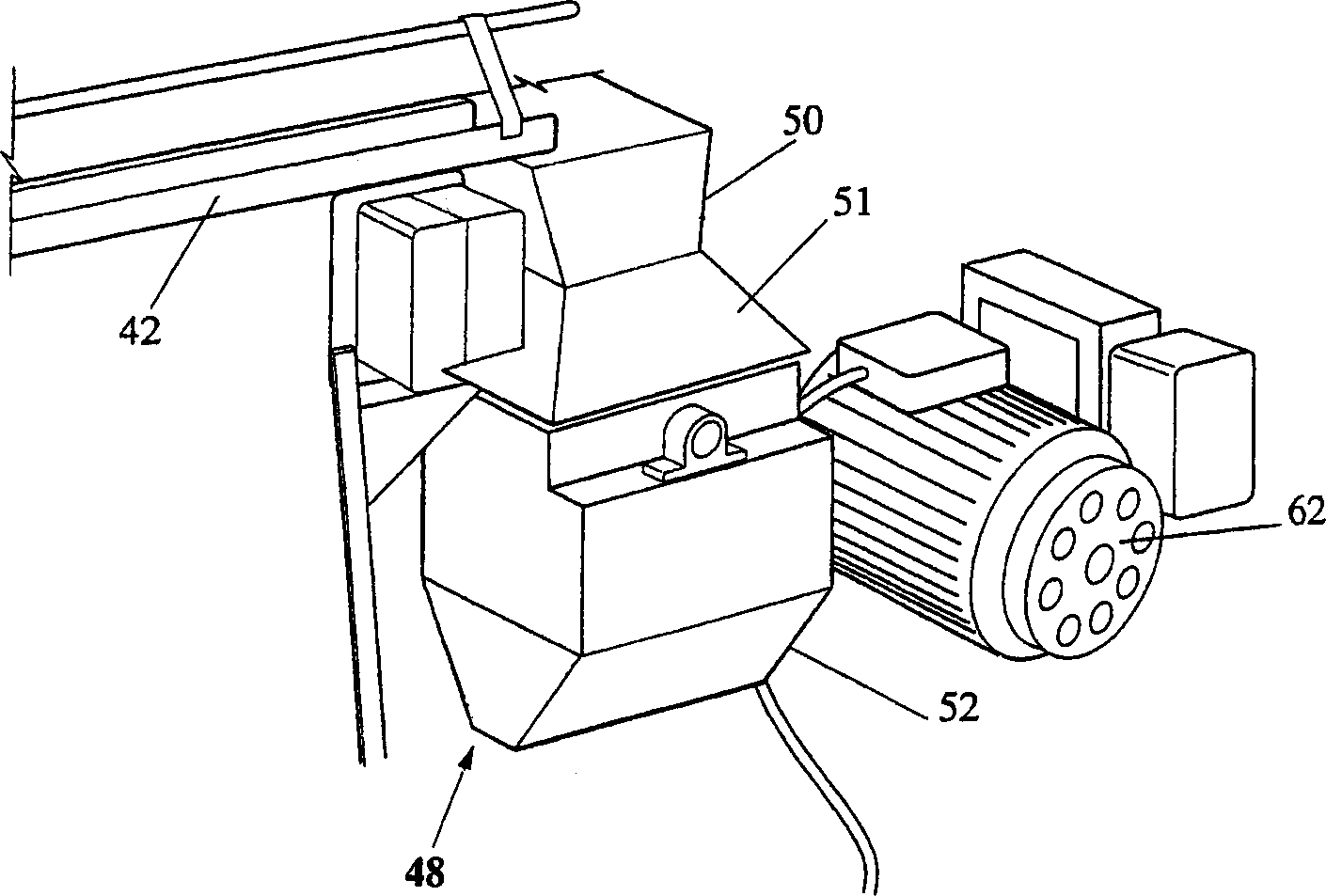

[0093] A production line 10 for ideal meat substitute production using the ingredients listed in Table 2 will be described.

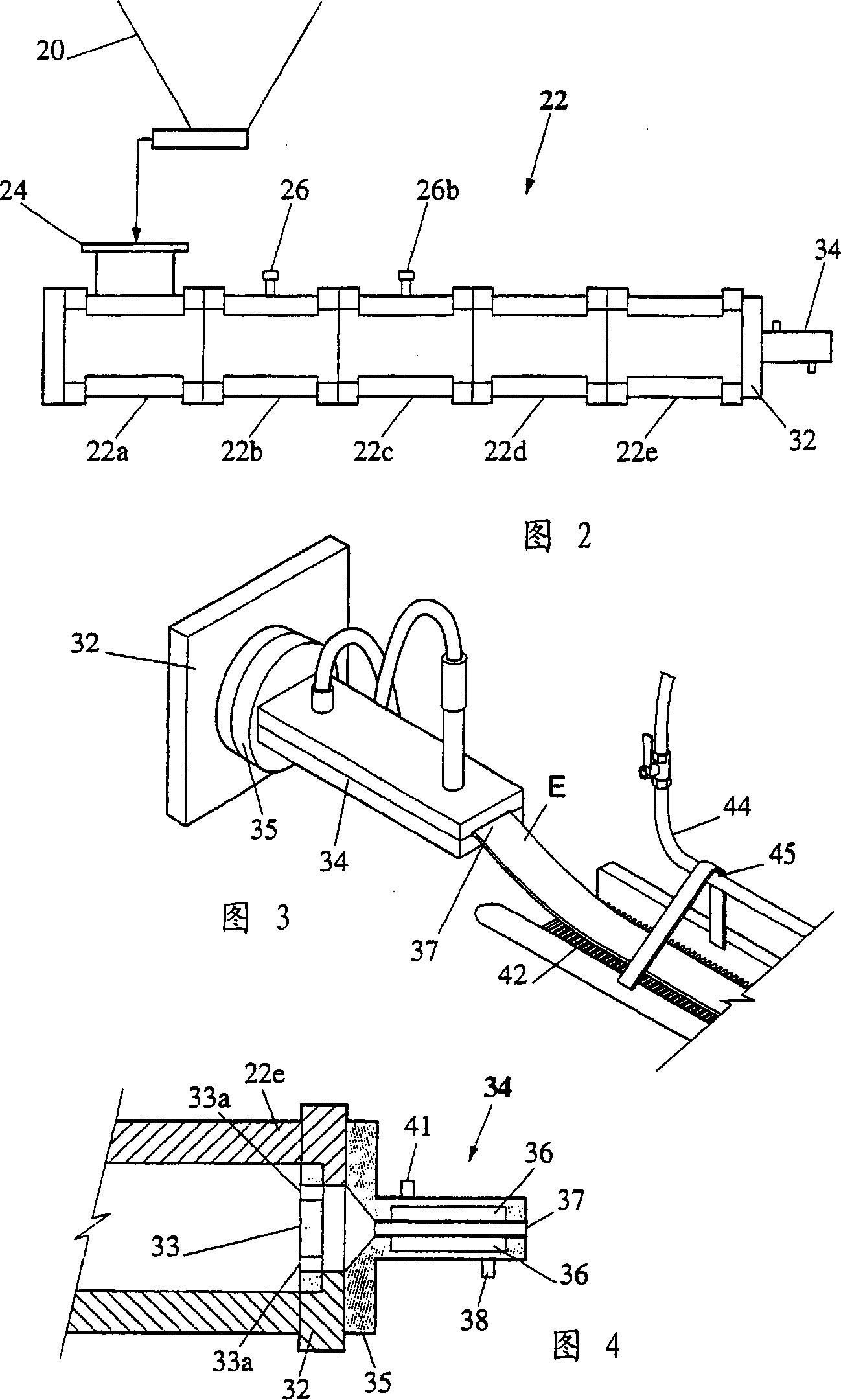

[0094] The ingredients were premixed in the ribbon mixer 18 in the weight ranges shown in Table 2 and metered into the extruder 22 using a mass bar material hopper 20 . The moisture content of the dry ingredient mixture is generally in the range of 9 to 14% by weight. Water is metered through injection port 26 into either the first or second portion of the extruder barrel. It is also possible to use steam, which is metered into the second or third barrel section of the extruder.

[0095] The extruder screws convey the wet mixture towards the outlet at the last extruder barrel 22e, whereby the mixture is subjected to greater shear and pressure. The temperature in the barrel section is generally set between 60°C and 140°C, with higher temperatures present in the middle barrel section where plastification and "melting" of the dry raw material is most eff...

example 2

[0105] Specific examples of meat substitutes produced according to the invention and specific parameters used in the production process are described below.

[0106] Precursors with a fibrous striated structure and meat substitute pieces similar to tuna white meat were prepared using the above method and apparatus as follows:

[0107] The ingredients listed in Table 4 were weighed out as indicated, pulverized through a hammer mill fitted with a screen size 1.2-2 mm, and pre-mixed in a ribbon mixer for 4 minutes.

[0108] Table 4

[0109] Composition Weight percent (%)

[0110] Defatted soybean meal 51.5

[0111] Whole Wheat Bran 42

[0112] Dicalcium phosphate 5

[0113] Vitamin 0.18

[0114] Minerals 0.2

[0115] Sulfur 0.1

[0116] Flavor 1.0

[0117] Pigment 0.02

[0118] The blended mixture was then fed into a hopper and metered into an extruder (Werner & Pfleiderer C58, fitted with 5 barrel sections) at a rate of 40 kg / hr. Water was fed at a rate of 32 kg / hr at...

example 3

[0129] The matrix with fibrous striae structure and the meat substitute block similar to beef tendon are prepared as follows by utilizing the above-mentioned method and device:

[0130] The ingredients listed in Table 6 were weighed and shown here and pulverized by a hammer mill fitted with a 1.2-2 mm screen and premixed in a ribbon mixer for 4 minutes.

[0131] Table 6

[0132] Composition Weight percent (%)

[0133] Whole Wheat Bran 42

[0134] Soy concentrate 41.6

[0135] Fiber 10.0

[0136] Dicalcium phosphate 5

[0137] Pigment 0.6

[0138] Salt 0.5

[0139] Vitamin 0.2

[0140] Sulfur 0.1

[0141] The blended mixture was then fed into a hopper and metered at a rate of 40 kg / hr into an extruder (Werner & Pfleiderer C58, fitted with 5 barrel sections). The emulsified beef liver was fed at a rate of 50 kg / hr into the barrel section adjacent to the feeding section. The screw speed of the extruder was set at 280. The temperature of the barrel was adjusted to the v...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com