Stretching-resistant high-temperature-resistant aerospace cable and preparation method thereof

An aerospace and high-temperature-resistant technology, applied in cable/conductor manufacturing, insulating cables, insulating conductors/cables, etc., can solve problems such as poor compatibility, crystallization, and unfavorable use, and achieve improved thermal stability and improved resistance. Ability to withstand and improve the effect of tensile strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

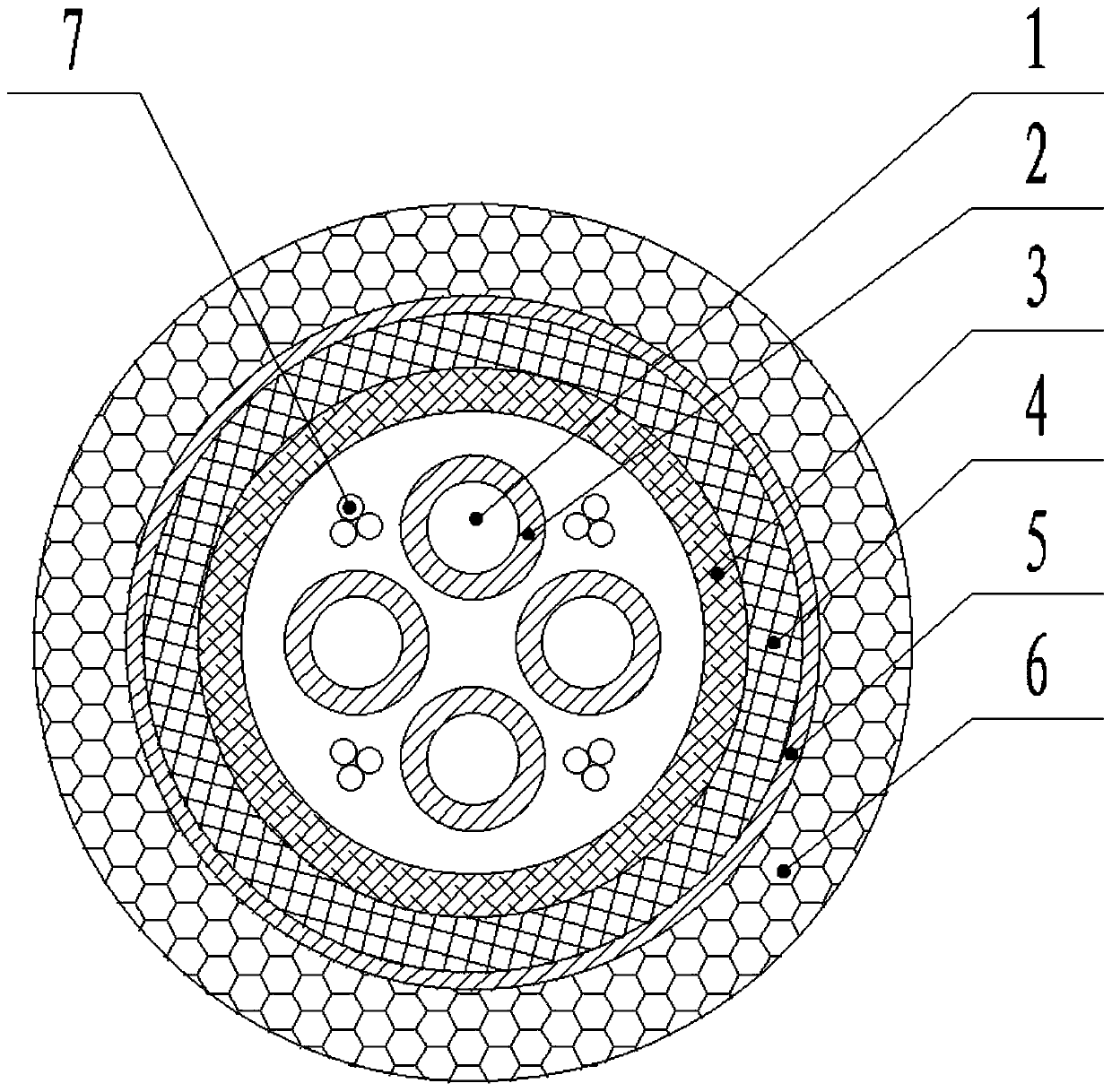

[0038] like figure 1 Shown: A stretch-resistant and high-temperature resistant aerospace cable, including a high-temperature resistant sheath layer from outside to inside, a flame-retardant semi-conductive cloth tape layer wrapped, a glass fiber braided layer, a composite heat-insulating layer wrapped and a cable core ;

[0039] The cable core is composed of a plurality of wires twisted, and the wires are filled with aramid fibers. The wires include a core material and a polyimide wrapping wrapped around the core material; the core material includes a plurality of nickel-plated Copper alloy wires are stranded, and 20.5% mass fraction of nano-inorganic particles are added to the polyimide wrapping. The nano-inorganic particles are made of TiO with a particle size of 10-20nm 2 Particles and Al with a particle size of 50-100nm 2 o 3 The particles are mixed according to the weight to weight ratio of 5: 1;

[0040]The composite insulation layer wrapping includes synthetic mica ...

Embodiment 2

[0052] like figure 1 Shown: A stretch-resistant and high-temperature resistant aerospace cable, including a high-temperature resistant sheath layer from outside to inside, a flame-retardant semi-conductive cloth tape layer wrapped, a glass fiber braided layer, a composite heat-insulating layer wrapped and a cable core ;

[0053] The cable core is composed of a plurality of wires twisted, and the wires are filled with aramid fibers. The wires include a core material and a polyimide wrapping wrapped around the core material; the core material includes a plurality of nickel-plated Copper alloy wires are stranded, and 21% mass fraction of nano-inorganic particles are added to the polyimide wrapping. The nano-inorganic particles are made of TiO with a particle size of 10-20nm 2 Particles and Al with a particle size of 50-100nm 2 o 3 The particles are mixed according to the weight to weight ratio of 3:1;

[0054] The composite insulation layer wrapping includes synthetic mica pa...

Embodiment 3

[0066] like figure 1 Shown: A stretch-resistant and high-temperature resistant aerospace cable, including a high-temperature resistant sheath layer from outside to inside, a flame-retardant semi-conductive cloth tape layer wrapped, a glass fiber braided layer, a composite heat-insulating layer wrapped and a cable core ;

[0067] The cable core is composed of a plurality of wires twisted, and the wires are filled with aramid fibers. The wires include a core material and a polyimide wrapping wrapped around the core material; the core material includes a plurality of silver-plated Copper alloy wires are stranded, and 20.5% mass fraction of nano-inorganic particles are added to the polyimide wrapping. The nano-inorganic particles are made of TiO with a particle size of 10-20nm 2 Particles and Al with a particle size of 50-100nm 2 o 3 The particles are mixed according to the weight to weight ratio of 3: 1;

[0068] The composite insulation layer wrapping includes synthetic mica...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com