Composite polishing pad and preparation method thereof

A composite polishing and polishing pad technology, which is applied in the direction of grinding/polishing equipment, manufacturing tools, metal processing equipment, etc., can solve the problems of difficult fixing of polishing pads, high hardness, scratches, etc., to improve hardness and flatness, reduce Less scratches and scratches

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

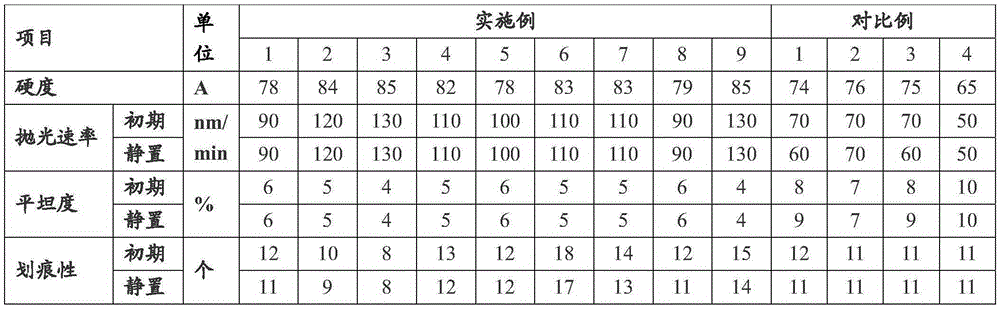

Examples

Embodiment 1

[0045] A preparation method of a composite polishing pad, comprising the following steps:

[0046] 1) Non-woven fabric pretreatment:

[0047] a) The fiber fineness is 1D and the area is 1m 2 And when the thickness is 1mm, the PET staple fiber needle-punched non-woven fabric with a weight of 100g is put into an oven, and the temperature is 170°C and the pressure is 1.8kPa. Cool down to room temperature to obtain a flattened non-woven fabric;

[0048] b) Immerse the flattened non-woven fabric obtained in step a) in a polyurethane adhesive with a viscosity of 200 mPa·s and a mass fraction of 5%, take it out after completely soaking, and air-dry at room temperature to obtain a non-woven fabric substrate;

[0049] 2) Prepare polymer solution:

[0050] 1) dissolving the polyurethane resin in N,N-dimethylformamide to prepare a uniform and transparent polyurethane solution with a mass fraction of 25%;

[0051] Ⅱ) adding cross-linked PMMA microspheres to the polyurethane solution o...

Embodiment 2

[0058] A preparation method of a composite polishing pad, comprising the following steps:

[0059] 1) Non-woven fabric pretreatment:

[0060] a) The fiber fineness is 0.1D and the area is 1m 2 And when the thickness is 1mm, the PET staple fiber needle-punched non-woven fabric with a weight of 180g is put into an oven, and the temperature is 190°C and the pressure is 1kPa. Cool to room temperature to obtain a flattened non-woven fabric;

[0061] b) Immerse the flattened non-woven fabric obtained in step a) in a polyurethane adhesive with a viscosity of 160 mPa·s and a mass fraction of 4%, take it out after completely soaking, and air-dry at room temperature to obtain a non-woven fabric substrate;

[0062] 2) Prepare polymer solution:

[0063] 1) dissolving the polyurethane resin in N,N-dimethylformamide to prepare a uniform and transparent polyurethane solution with a mass fraction of 22.5%;

[0064] Ⅱ) adding cross-linked PMMA microspheres to the polyurethane solution obta...

Embodiment 3

[0068] A preparation method of a composite polishing pad, comprising the following steps:

[0069] 1) Non-woven fabric pretreatment:

[0070] a) The fiber fineness is 0.05D and the area is 1m 2 And when the thickness is 1mm, the PET staple fiber needle-punched non-woven fabric with a weight of 200g is put into an oven, and the temperature is 210°C and the pressure is 0.2kPa. Cool down to room temperature to obtain a flattened non-woven fabric;

[0071] b) Immerse the flattened non-woven fabric obtained in step a) in a polyurethane adhesive with a viscosity of 120 mPa·s and a mass fraction of 3%, take it out after completely soaking it, and air-dry it at room temperature to obtain a non-woven fabric substrate;

[0072] 2) Prepare polymer solution:

[0073] 1) dissolving the polyurethane resin in N,N-dimethylformamide to prepare a uniform and transparent polyurethane solution with a mass fraction of 20%;

[0074] Ⅱ) adding cross-linked PMMA microspheres to the polyurethane s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com