Woven polar fleece fabric and production method thereof

A production method and fabric technology, applied in the direction of fabric surface trimming, weaving, fabrics, etc., can solve the problems of gas that cannot be removed in time, easy to deform, easy to hook and pilling, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0030] The present invention will be further described in conjunction with the accompanying drawings and specific embodiments.

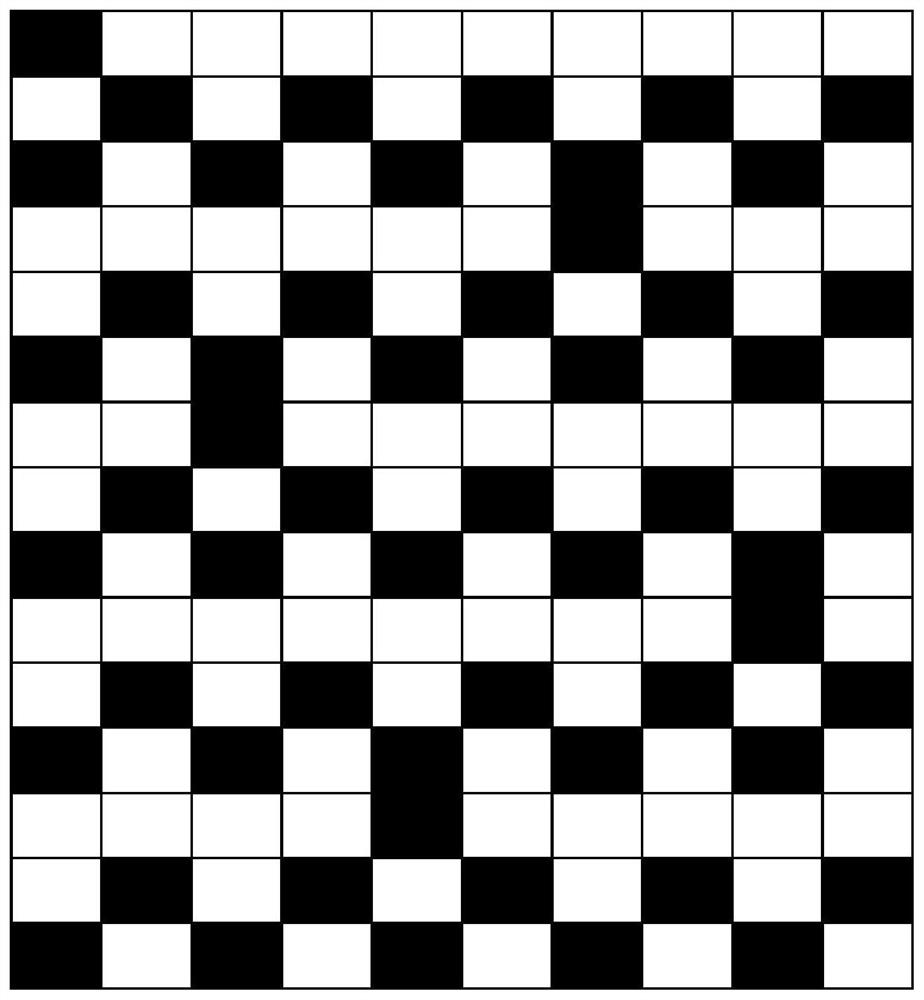

[0031] Such as figure 1 As shown, a kind of woven fleece fabric provided in this embodiment includes warp yarns and weft yarns, and the warp yarns and weft yarns are interwoven to form a three-dimensional weave structure on both sides of the fabric, and brush the fleece on the back of the fabric , so that it has a polar fleece structure on the back. Change the traditional woven fabric + knitted polar fleece to the back of the woven fabric with a three-dimensional structure on the front and back, which directly achieves the fleece effect. The single-layer fabric has two layers of style, so it will not be layered when worn , fall off. Moreover, the overall ventilation effect is very good, it has a good thermal insulation effect, and has excellent ventilation performance. The velvet feel can achieve the effect of knitted fleece, and the elasticity is...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com