Modified acrylic ester waterproof coating

An acrylic and waterproof coating technology, used in antifouling/underwater coatings, polyurea/polyurethane coatings, epoxy resin coatings, etc. and other problems, to achieve the effect of good stain resistance, good comprehensive performance and simple construction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

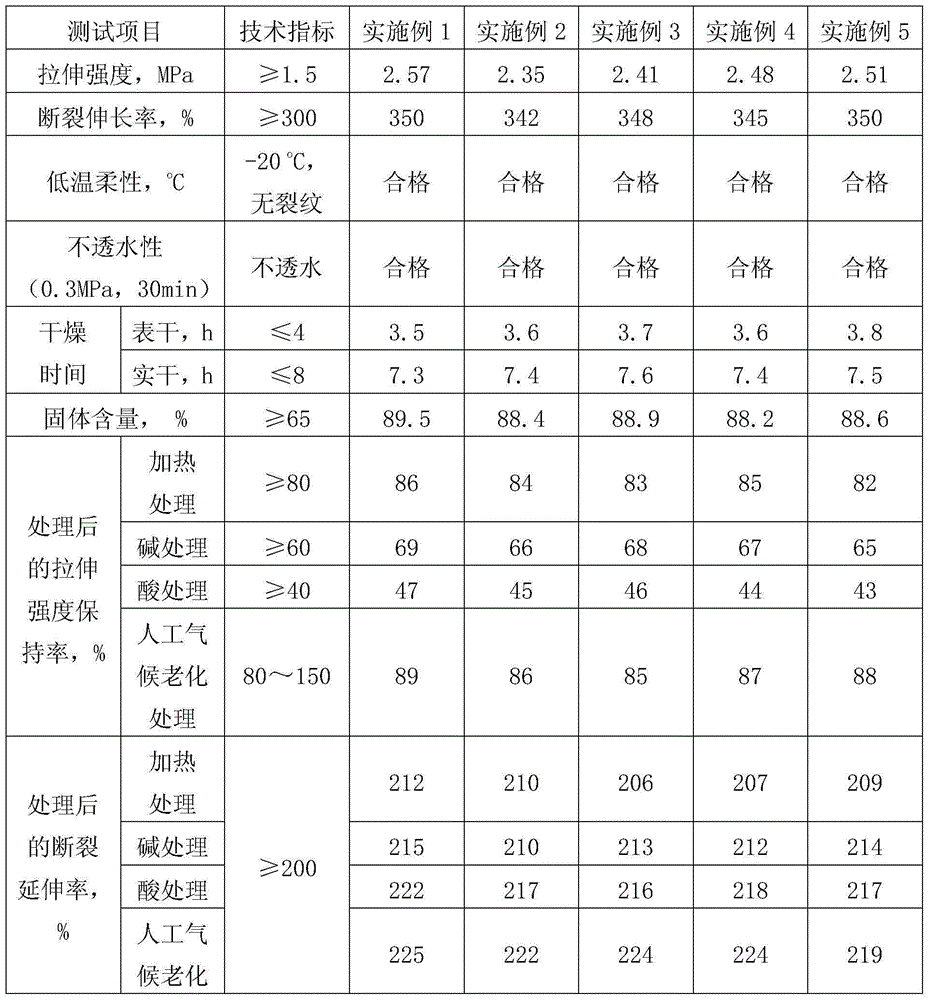

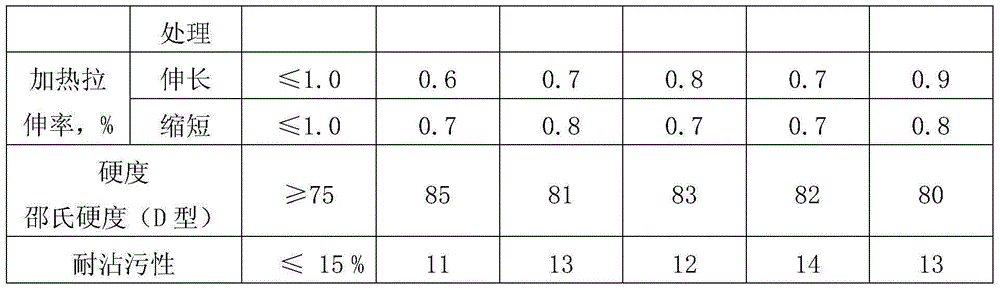

Examples

Embodiment 1

[0032] A modified acrylate waterproof coating, which is made of the following components in proportion by weight: 6 parts of acrylate emulsion, 7 parts of styrene monomer modified acrylate emulsion, 7 parts of polyurethane modified acrylate emulsion, cyclic 8 parts of oxygen resin modified acrylate emulsion, 8 parts of silicone modified acrylate emulsion, 9 parts of inorganic silicon emulsion modified acrylate emulsion, 4 parts of fluorocarbon surfactant, 2 parts of nano titanium dioxide, 3 parts of carbon nanotube, 13 parts of talcum powder, 9 parts of calcium carbonate, 3 parts of montmorillonite, 0.2 parts of sepiolite / sodium polyacrylate compound, 0.5 parts of sodium hexametaphosphate, 0.3 parts of polyether modified siloxane, diphthalic acid 1.5 parts of butyl ester, 0.6 parts of hydroxyethyl cellulose, 0.4 parts of ascorbic acid, 0.6 parts of glass fiber, 0.2 parts of 1,2-benzisothiazolin-3-one, 0.5 parts of emulsified paraffin, 30 parts of water.

Embodiment 2

[0034] A modified acrylate waterproof coating, which is made of the following components in proportion by weight: 5 parts of acrylate emulsion, 5 parts of styrene monomer modified acrylate emulsion, 6 parts of polyurethane modified acrylate emulsion, cyclic 6 parts of oxygen resin modified acrylate emulsion, 6 parts of silicone modified acrylate emulsion, 7 parts of inorganic silicon emulsion modified acrylate emulsion, 2 parts of fluorocarbon surfactant, 1 part of nano-titanium dioxide, 1 part of carbon nanotube, 10 parts of talcum powder, 8 parts of calcium carbonate, 2 parts of montmorillonite, 0.1 part of sepiolite / sodium polyacrylate compound, 0.3 part of sodium hexametaphosphate, 0.2 part of polyether modified siloxane, diphthalate 1 part of butyl ester, 0.5 part of hydroxyethyl cellulose, 0.2 part of ascorbic acid, 0.4 part of glass fiber, 0.1 part of 1,2-benzisothiazolin-3-one, 0.4 part of emulsified paraffin, 25 parts of water.

Embodiment 3

[0036] A modified acrylate waterproof coating, which is made of the following components in proportion by weight: 8 parts of acrylate emulsion, 9 parts of styrene monomer modified acrylate emulsion, 8 parts of polyurethane modified acrylate emulsion, cyclic 10 parts of oxygen resin modified acrylate emulsion, 10 parts of silicone modified acrylate emulsion, 10 parts of inorganic silicon emulsion modified acrylate emulsion, 6 parts of fluorocarbon surfactant, 4 parts of nano-titanium dioxide, 4 parts of carbon nanotube, 16 parts of talcum powder, 10 parts of calcium carbonate, 4 parts of montmorillonite, 0.3 parts of sepiolite / sodium polyacrylate compound, 0.7 parts of sodium hexametaphosphate, 0.4 parts of polyether modified siloxane, diphthalic acid 2 parts of butyl ester, 0.7 part of hydroxyethyl cellulose, 0.6 part of ascorbic acid, 0.8 part of glass fiber, 0.3 part of 1,2-benzisothiazolin-3-one, 0.6 part of emulsified paraffin, 35 parts of water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com