Porous high-entropy alloy oxide film and preparation method thereof

A technology of oxide film and high-entropy alloy, which is applied in the field of high-entropy alloy, can solve the problems of low hardness and easy change of pores, and achieve the effect of high hardness, high production efficiency and uniform pores

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0033] (1) Substrate preparation: Place the Si substrate polished on one side in acetone, ethanol and deionized water for ultrasonic cleaning in sequence, the time is 30min, and the ultrasonic frequency is 100Hz;

[0034] (2) Lofting: Then fix the substrate cleaned in step (1) on the baffle, put it into the sample delivery room of the radio frequency magnetron sputtering equipment for vacuuming, and the vacuum degree is higher than 5×10 -3 Torr, then turn off the chamber vacuum pump;

[0035] (3) Pre-sputtering: the CoCrFeMnNi target and the Al target are respectively pre-sputtered to remove oxides and dirt on the target surface. The purity of the CoCrFeMnNi and Al targets is 99.99%; the cavity is vacuum during pre-sputtering degrees higher than 2×10 -7 Torr, the voltage is 50V, the flow rate of high-purity argon gas is 20sccm, the working pressure is 3mTorr, the sputtering time is 30min, and the chamber temperature is cooled to 20°C after sputtering;

[0036] (4) Sample del...

Embodiment 2~5

[0049] The preparation method and test standard method of the porous high-entropy alloy oxide film of embodiments 2-5 are all the same as embodiment 1, the difference is that the time of sealing tube heat treatment is different, as shown in table 1:

[0050] Table 1

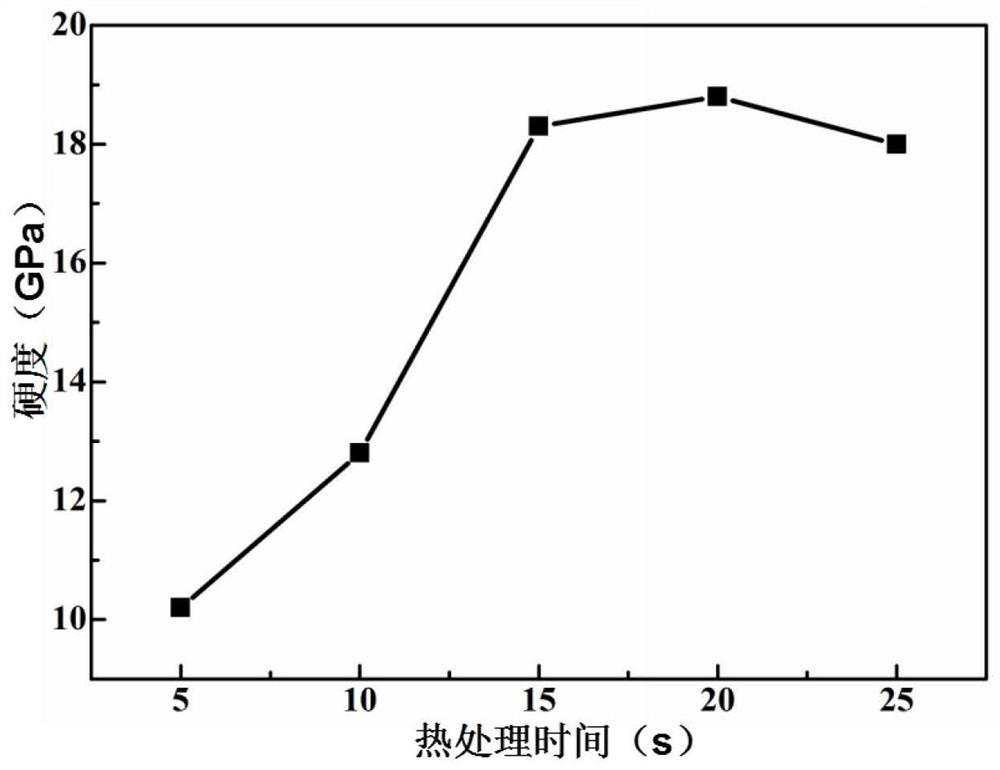

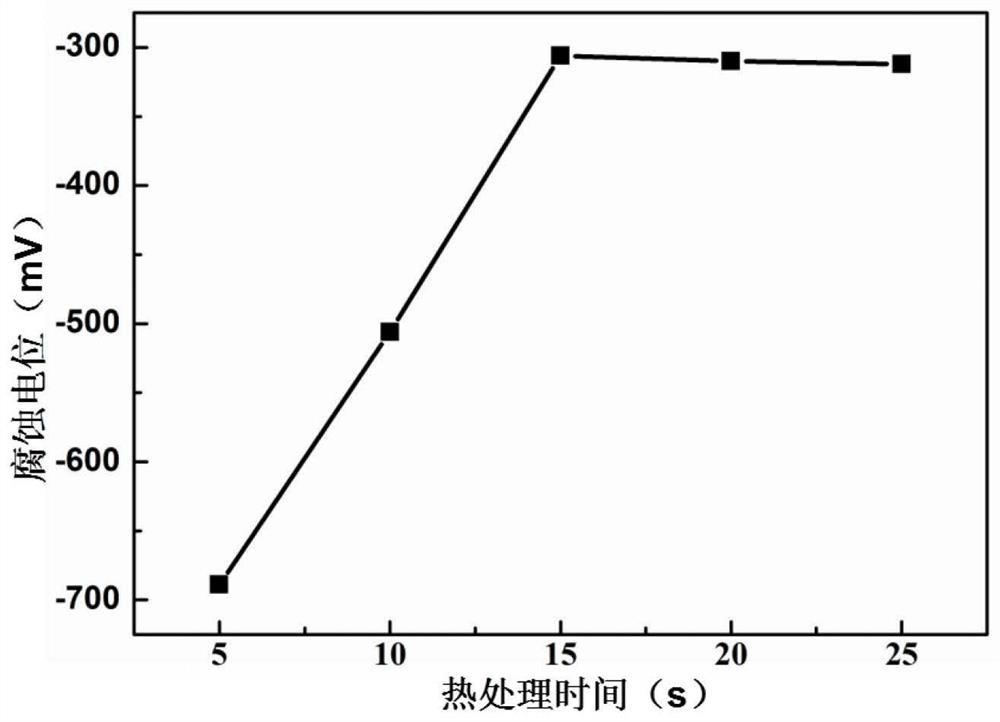

[0051] Group / Project Heat treatment time / s Hardness / GPa Corrosion potential / V Example 1 5 10.2 -0.689 Example 2 10 12.8 -0.506 Example 3 15 18.3 -0.306 Example 4 20 18.8 -0.310 Example 5 25 17.9 -0.315

[0052] figure 1 with figure 2 Respectively, the hardness and heat treatment time of the porous high-entropy alloy oxide film prepared in Examples 1 to 5 are the relationship diagrams between the corrosion potential and the heat treatment time. It can be seen that the heat treatment time of the porous high-entropy alloy oxide film prepared by the method of the present invention It has an important influence on the hardness of the film. As the heat trea...

Embodiment 6

[0054] (1) Substrate preparation: place the Si substrate polished on one side in acetone, ethanol and deionized water for ultrasonic cleaning in sequence, the time is 15min, and the ultrasonic frequency is 100Hz;

[0055] (2) Lofting: Then fix the substrate cleaned in step (1) on the baffle, put it into the sample delivery room of the radio frequency magnetron sputtering equipment for vacuuming, and the vacuum degree is higher than 5×10 -3 Torr, then turn off the chamber vacuum pump;

[0056] (3) Pre-sputtering: the CoCrFeMnNi target and the Al target are respectively pre-sputtered to remove oxides and dirt on the target surface. The purity of the CoCrFeMnNi and Al targets is 99.99%; the cavity is vacuum during pre-sputtering degrees higher than 2×10 -7 Torr, the voltage is 150V, the flow rate of high-purity argon gas is 40sccm, the working pressure is 5mTorr, the sputtering time is 20min, and the chamber temperature is cooled to 30°C after sputtering is completed;

[0057] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| hardness | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

| corrosion potential | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com