Aqueous polyester-acrylic resin hybrid body and preparation method

A technology of acrylic resin and water-based polyester, which is applied in the direction of polyester coatings and coatings, which can solve the problems of poor weather resistance and chemical resistance, and achieve the effects of good hydrophilicity, excellent storage stability and high hardness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

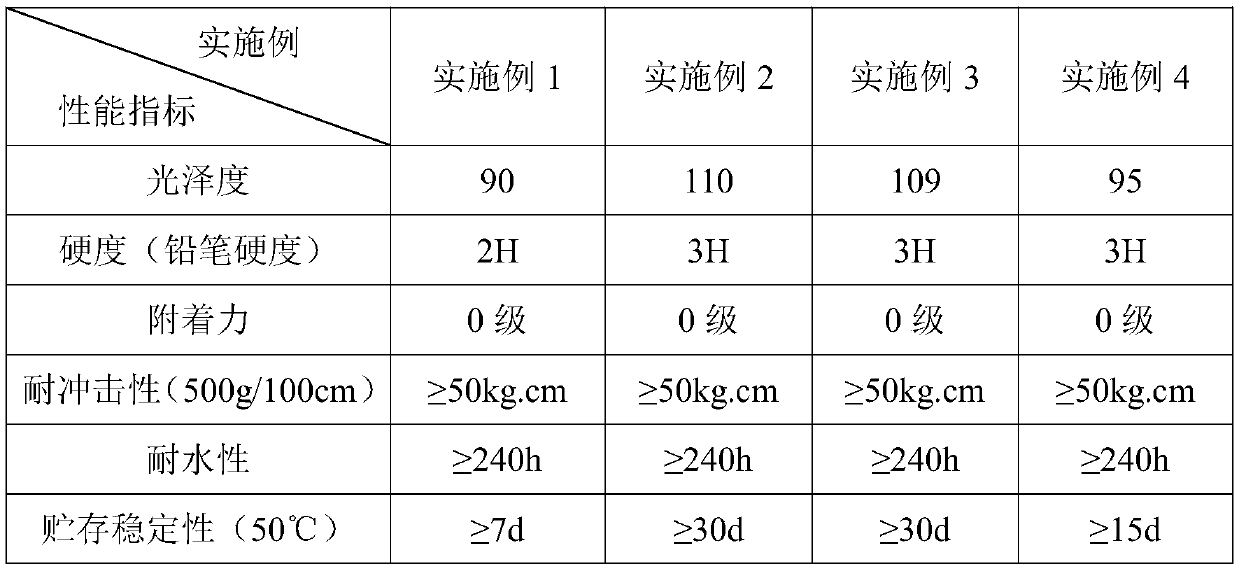

Examples

Embodiment 1

[0041] Step 1, the synthesis of water-based unsaturated polyester

[0042]26.39g of neopentyl glycol, 10.475g of trimethylolpropane, 15.645g of dimethylolpropionic acid, 28.275g of phthalic anhydride, 1.3195g of maleic anhydride, 28.275g of adipic acid, 0.11 g of catalyst monobutyltin oxide was added to a four-necked flask equipped with a temperature controller, a water separator, a condensing reflux pipe, and a stirrer, heated until the condensing reflux pipe began to reflux, kept for 1-2h, and added 8.85g (8 %) Xylene is fully refluxed with water, kept at 200°C for 1-3 hours, and the acid value is measured. When the acid value reaches the design acid value of 65mgKOH / g, cool down to 80-100°C and add 25g of ethylene glycol butyl ether to adjust the solid content to 80%. , cooled to 50°C and discharged. That is, a water-based unsaturated polyester resin is obtained.

[0043] Step 2, the synthesis of waterborne polyester-acrylic resin hybrid

[0044] Add the water-based unsa...

Embodiment 2

[0046] Step 1, the synthesis of water-based unsaturated polyester

[0047] 36.31 g of 2-butyl-2-ethyl-1,3 propanediol, 12.52 g of trimethylolpropane, 10.73 g of dimethylolpropionic acid, 28.62 g of 1,4-cyclohexanedicarboxylic acid , the maleic anhydride of 1.34g, the adipic acid of 22.36g, the catalyst monobutyltin oxide of 0.224g, add in the four-necked flask that temperature controller, water trap, condensation reflux pipe, stirrer are housed, Heat until the condensing reflux tube starts to reflux, keep warm for 1-2h, add 8.95g (8%) xylene to fully reflux with water, keep warm at 200°C for 2-3h, measure the acid value, when the acid value reaches the design acid value of 45mgKOH / g, Cool down to 80-100°C and add 25g propylene glycol butyl ether to adjust the solid content to 80%, cool down to 50°C and discharge. That is, a water-based unsaturated polyester resin is obtained.

[0048] Step 2, the synthesis of waterborne polyester-acrylic resin hybrid

[0049] Add the water-...

Embodiment 3

[0051] Step 1, the synthesis of water-based unsaturated polyester

[0052] 32.6g of 1,4-cyclohexanedimethanol, 13.01g of trimethylolpropane, 13.2g of dimethylolpropionic acid, 13.6g of phthalic anhydride, 13.58g of 1,4-cyclohexanedicarboxylic acid , the maleic anhydride of 1.34g, the adipic acid of 23.24g, the catalyst dibutyltin oxide of 0.224g, add in the four-necked flask that temperature controller, water trap, condensation reflux pipe, stirrer are housed, Heat until the reflux pipe starts to reflux, keep warm for 1-2h, add 8.85g (8%) xylene to fully reflux with water, keep warm at 200°C for 2-3h, measure the acid value, when the acid value reaches the design acid value of 55mgKOH / g, Cool down to 80-100°C and add 25g ethylene glycol butyl ether to adjust the solid content to 80%, cool down to 50°C and discharge. That is, a water-based unsaturated polyester resin is obtained.

[0053] Step 2, the synthesis of waterborne polyester-acrylic resin hybrid

[0054] Put the wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com