Rolling cutter bit

A technology of rolling knives and blade bodies, applied in the field of machining parts, can solve the problems of uneven force on the rolling surface, inconsistent hardness of the machined surface, unable to meet the requirements of the drawings, etc., so as to improve the machining accuracy, overcome the tool setting error, simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

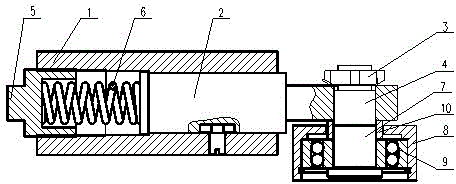

[0016] The present invention will be further explained below in conjunction with the accompanying drawings.

[0017] The invention discloses a rolling cutter head, which comprises a cutter shell 1, a cutter body 2 arranged in the cutter casing 1, one end of the cutter body 2 extends out of the cutter casing 1, and a rolling cutter head 4 is fixed at the port by a fastening bolt 3, and the other An adjusting bolt 5 is arranged at one end, and a spring 6 is arranged between the adjusting bolt 5 and the knife body 2 .

[0018] Wherein, the rolling cutter head 4 includes a mandrel 7, the upper end of the mandrel 7 is connected to the blade body 2 through a fastening bolt 5, and a roller 8 is provided at the lower end, and a self-aligning bearing is also provided between the mandrel 7 and the roller 8 9. The outer side of the mandrel 7 is covered with a transition sleeve 10; when the roller used by the self-aligning bearing is in use, it can automatically adjust according to the su...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com