Wear-resistant anti-cracking PU matt floor paint

A kind of floor paint, anti-cracking technology, applied in the direction of coating, polyurea/polyurethane coating, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] Prepare Part A:

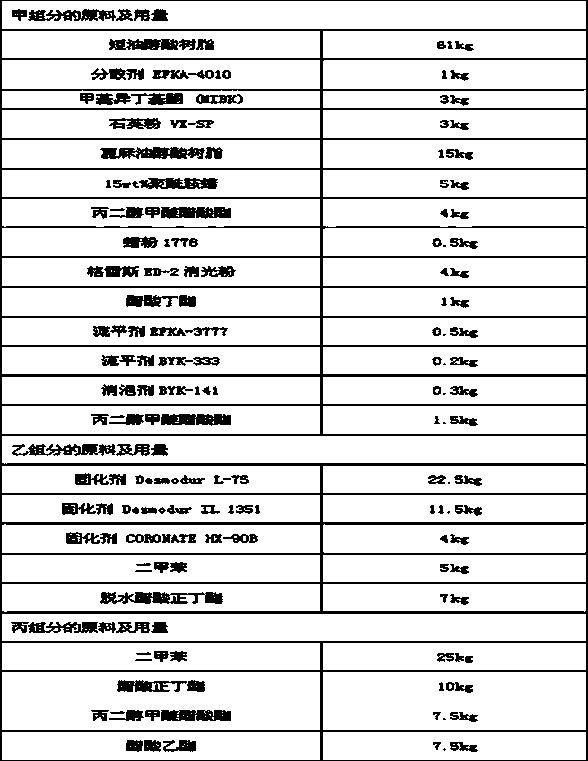

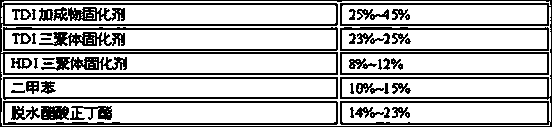

[0027] Select a clean and standard dispersing cylinder, and the production process: Add 45 kg of short oil alkyd resin, 1.2 kg of dispersant (EFKA-4010), 3 kg of methyl isobutyl ketone (MIBK) in sequence, at a low speed of 600~800 r / After adding 5 kg of quartz powder (VX-SP) at a speed of 1 min, disperse at a medium speed of 800~1200 r / min for 15~20 min until the fineness is ≤ 25 μm, and then add 20 kg of castor oil alkyd resin in sequence , 5 kg of 15wt% polyamide wax, 6 kg of propylene glycol methyl ether acetate, put into the dispersion tank, disperse at a medium speed of 800~1200r / min for 10 minutes until fully uniform, then add 1 kg of 1778 wax powder, matting powder (Grace ED-2) 7 kg, clean the side of the tank with 2 kg of butyl acetate, disperse at high speed for 10~15 minutes, until the fineness is ≤25 μm, add 1 kg of leveling agent EFKA-3777, 0.3 kg of leveling agent BYK-333, 0.5 kg of Foaming agent BYK-141, using 3 kg of propylene glycol m...

Embodiment 2

[0033] Prepare raw materials according to Table 1; adopt the same method as in Example 1 to prepare component A, component B and component C in sequence;

[0034] Adopt the same using method as embodiment 1;

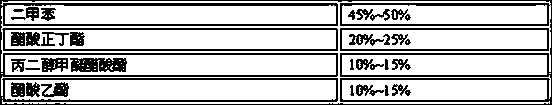

[0035] Table 1:

[0036]

Embodiment 3

[0038] According to the raw material parts by weight and the method of Example 1, the first component and the second component are prepared respectively;

[0039] Then get 36kg xylene, 20kg n-butyl acetate, 12kg propylene glycol methyl ether acetate, 12kg ethyl acetate;

[0040] Stir evenly to obtain component C; set aside;

[0041] Adopt the same method of use as in Example 1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com