Composite micropowder and method for manufacturing the same, ceramic paint, and protection coating

一种复合材料、陶瓷涂料的技术,应用在涂层、薄料处理、运输和包装等方向,能够解决无法长期保持不黏性等问题,达到好兼容性及不黏性、优异不黏性、步骤简单的效果

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0020] The present invention also provides a method for preparing the composite material micropowder, which has the advantages of simple steps, no need for thermal cracking or radiation cracking, safety and environmental protection, and low cost.

[0021] In one embodiment of the present invention, the preparation method of composite material micropowder comprises: uniformly mixing 100 parts by weight of fluoropolymer and 10-140 parts by weight of silane. Depending on the mixing situation, an appropriate solvent can be added to wet the fluoropolymer. The solvent is not particularly limited, and any solvent that can wet the fluoropolymer can be used. Alcohols such as methanol, ethanol, isopropanol, or benzene can be used Such as toluene or xylene.

[0022] In one embodiment of the present invention, 60-80% of 10-140 parts by weight of silane can be further replaced with silica sol, silicate such as sodium silicate, or a combination of the above to further improve the resistance...

Embodiment 1

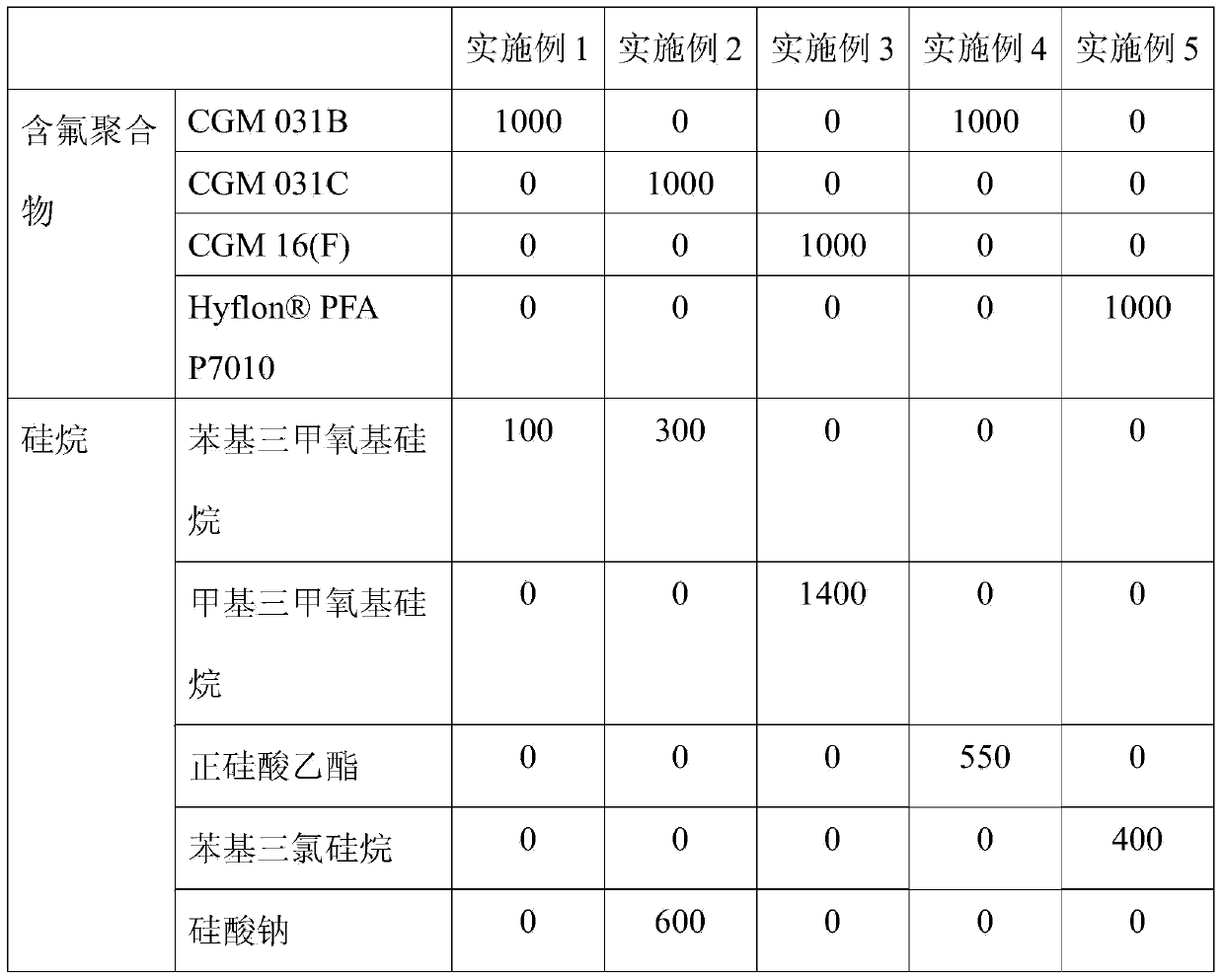

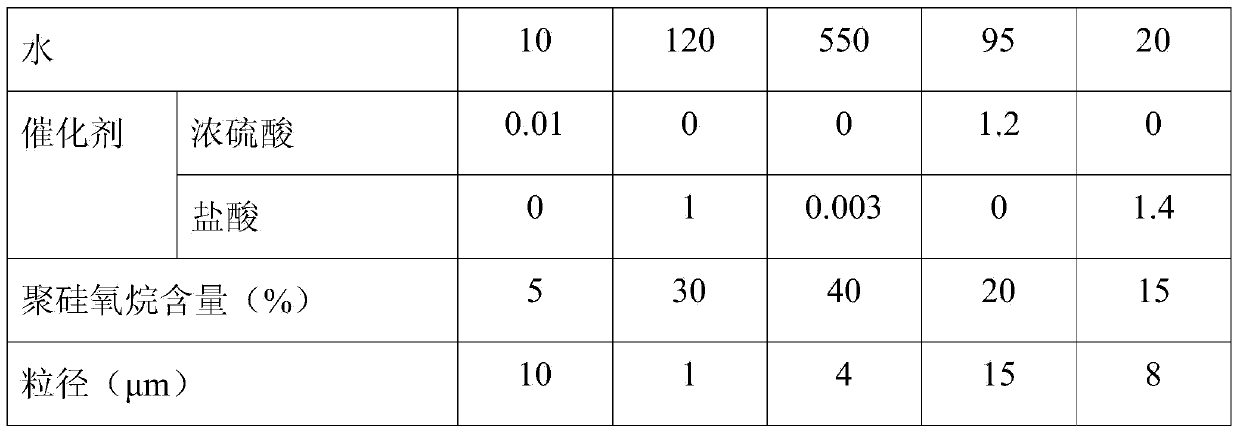

[0057] Embodiment 1 (composite material micropowder comprising PTFE)

[0058] Add 1000g of PTFE powder (CGM031B) into the reaction vessel, add an appropriate amount of methanol, stir to wet the PTFE powder, then add 100g of phenyltrimethoxysilane and stir evenly, then add 0.01g of concentrated sulfuric acid as a catalyst and mix evenly, and finally add 10g of water, control the reaction temperature not to exceed 45°C for 4 hours.

[0059] The mixture was heated to boiling to remove moisture, then filtered with a 100-mesh filter cloth to obtain a wet powder, and dried at 150° C. for 4 hours to obtain a dry powder (weighing 1053 g). The dry powder is classified by jet crushing to obtain PTFE-containing composite material powder with a particle size of 10 μm.

Embodiment 2

[0060] Embodiment 2 (composite material micropowder comprising PTFE)

[0061] Add 1000g of PTFE powder (CGM031C) into the reaction vessel, then add 300g of phenyltrimethoxysilane and 600g of sodium silicate and stir evenly, then add 1g of hydrochloric acid as a catalyst and mix well, and finally add 120g of water, and control the reaction temperature not to exceed 45°C React for 6 hours.

[0062] The mixture was heated to boiling to remove moisture, then filtered with a 100-mesh filter cloth to obtain a wet powder, and dried at 200° C. for 3 hours to obtain a dry powder (weighing 1430 g). The dry powder is classified by jet crushing to obtain PTFE-containing composite material powder with a particle size of 1 μm.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| solid containing ratio | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com