Polyurethane acrylate modified ultraviolet light cured water-dilutable resin and preparation method thereof

A technology of polyurethane acrylate and water-based resin, applied in the direction of coating, etc., can solve problems such as skin irritation, insufficient hardness and rigidity, and environmental pollution, and achieve reduced toxicity and irritation, good wear resistance and hardness, and excellent comprehensive performance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

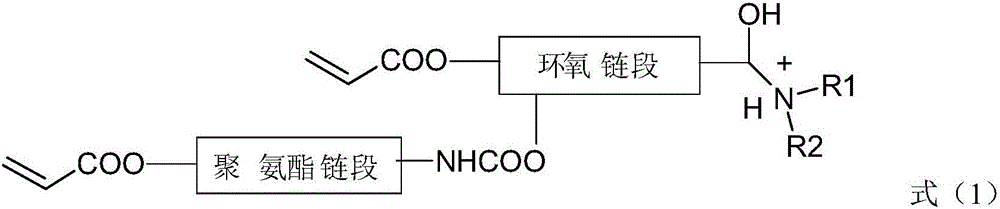

[0042] A kind of urethane acrylate modified UV-curable water-based resin, the structure of the urethane acrylate-modified UV-cured water-based resin is as shown in formula (1):

[0043]

[0044] Among them, R1 and R2 are CH 2 CH 3 .

[0045] It is prepared by the following steps:

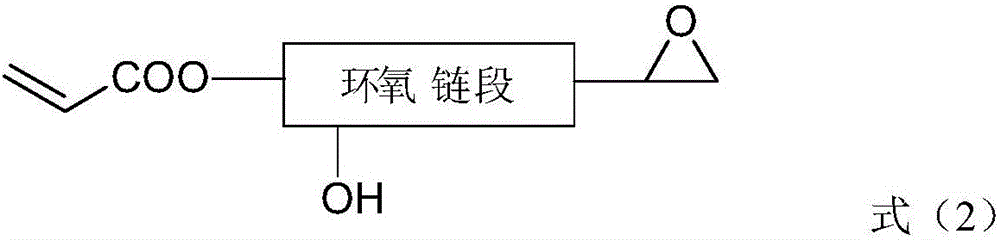

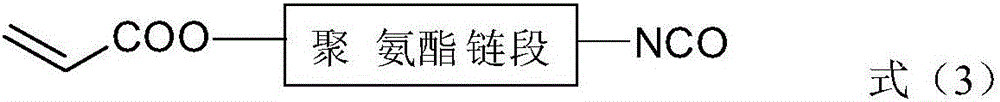

[0046] Step S1: Synthesis of partial esterification of acrylic acid and epoxy;

[0047] Add 500g of tetrabromobisphenol A epoxy resin into a 1000mL three-necked flask, heat the oil bath to 100°C, and stir; in addition, add the catalyst tetrakis(acetylacetonate)zirconium complex and p-hydroxyanisole to the metered acrylic acid, and add it dropwise In the epoxy resin, wherein, the molar ratio of the epoxy group to the acrylic acid is 2:1, the mass percent of the catalyst tetrakis(acetylacetonate) zirconium complex is 0.7%, and the p-hydroxyanisole The mass percentage accounted for is 0.5%. After reacting for 4 hours, the acid value of the system is less than 3mgKOH / g by alkali titration, that i...

Embodiment 2

[0056] A urethane acrylate modified UV-curable water-based resin, the structure of the urethane acrylate-modified UV-curable water-based resin is as shown in formula (1), wherein R1 and R2 are CH 2 CH 2 CH 3 .

[0057] It is prepared by the following steps:

[0058] Step S1: Add 450g of bisphenol A epoxy (epoxy E44) into a 1000mL three-necked flask, heat the oil bath to 110°C, stir, add the catalyst triphenylphosphine and p-hydroxyanisole to the other metered acrylic acid, add dropwise to the ring In epoxy resin, wherein, the molar ratio of epoxy group and acrylic acid is 2:1, the mass percent that described catalyst triphenylphosphine accounts for is 0.5%, and the mass percent that described p-hydroxyanisole accounts for is 0.3 %, the system acid value is less than 3mgKOH / g after reacting for 3.5h, promptly obtains the epoxy acrylate monoester of formula (2) structure;

[0059] Step S2: Add 2 mol of diphenylmethane diisocyanate (MDI) to a three-necked flask and heat to 70...

Embodiment 3

[0064] A urethane acrylate modified UV-curable water-based resin, the structure of the urethane acrylate-modified UV-curable water-based resin is as shown in formula (1), wherein R1 and R2 are CH 2 CH 2 Oh.

[0065] It is prepared by the following steps:

[0066] Step S1: Add 220g novolac epoxy resin into a 500mL three-necked flask, heat the oil bath to 115°C, and stir; add the catalyst triethanolamine and p-hydroxyanisole to the other metered acrylic acid, and add them dropwise to the epoxy resin, wherein, The molar ratio of epoxy group to acrylic acid is 2:1, the mass percentage of the catalyst triethanolamine is 0.8%, and the mass percentage of p-hydroxyanisole is 0.8%, and after 3 hours of reaction, the alkali Titrate until the acid value of the system is less than 3mgKOH / g, to obtain the epoxy acrylate monoester of formula (2);

[0067] Step S2: Add 2 mol of isophorone diisocyanate (IPDI) to a 1000 mL three-necked flask, and heat to 80° C.; add dibutyltin dilaurate to ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com