High-efficiency low-pollution plasma source

A plasma source, low-pollution technology, applied in the direction of plasma, electrical components, etc., can solve the problems of increasing the structure complexity and control difficulty of the Hall ion source, affecting the application range of the Hall ion source, and the small working discharge voltage range , to achieve the effects of improving the beam extraction efficiency and the ion energy in the beam, high beam extraction efficiency, and improving the utilization rate of the discharge current

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0031] The present invention will be further described below by means of the accompanying drawings and specific embodiments. The accompanying drawings and descriptions are to be regarded as illustrative rather than restrictive, and the present invention is not limited to the disclosed specific embodiments, and various improvements made according to the spirit of the present invention are included in the scope of protection required by the claims of the present invention Inside.

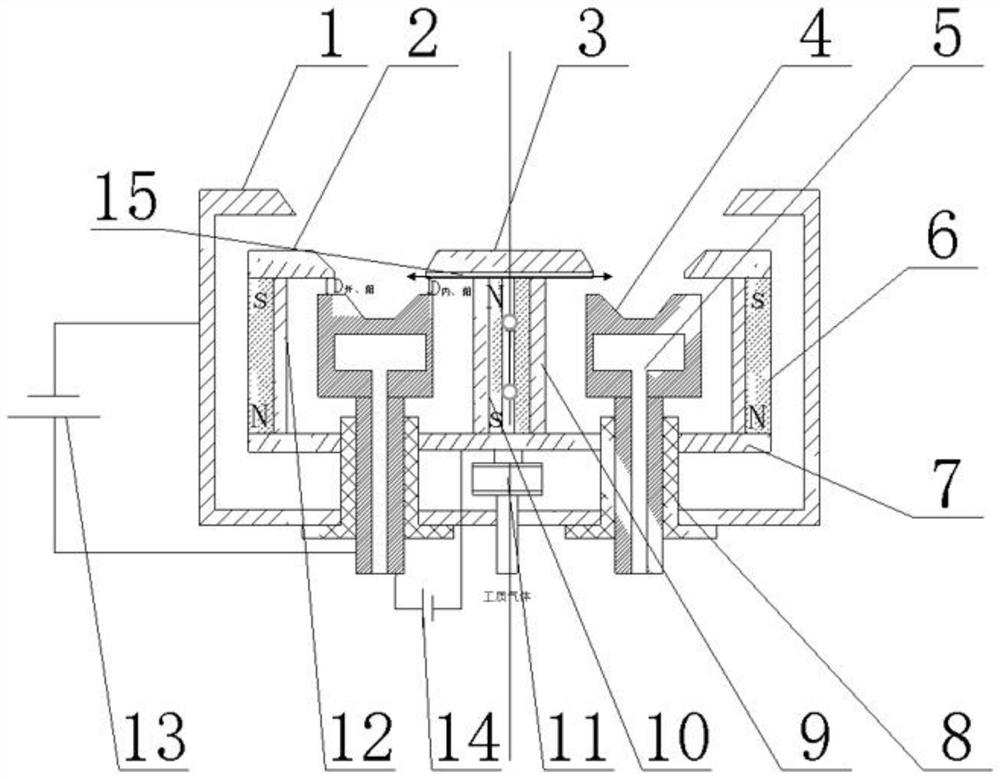

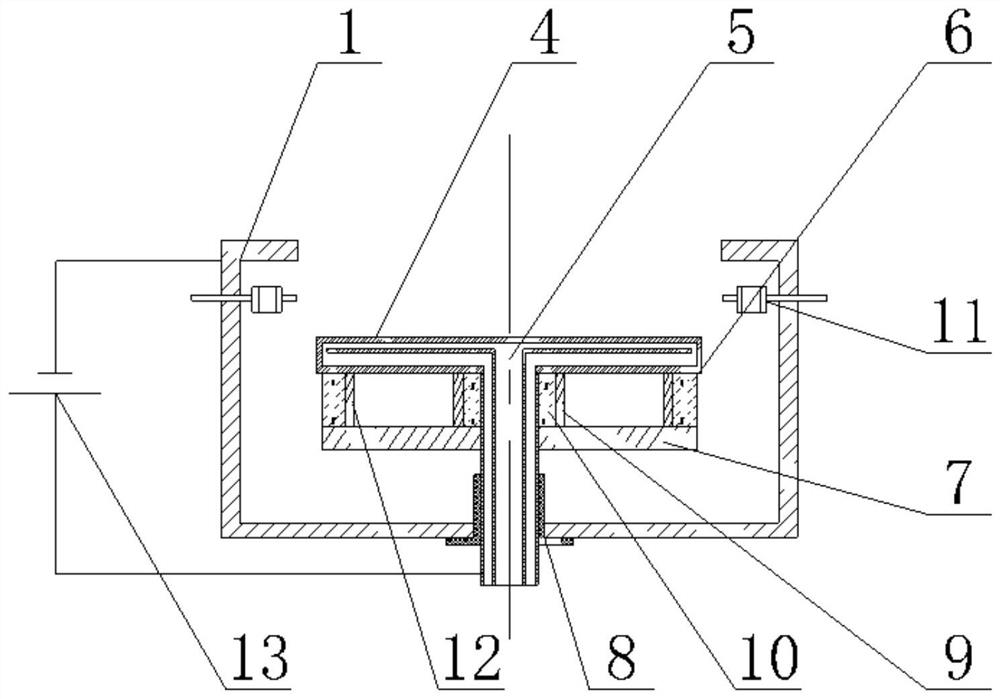

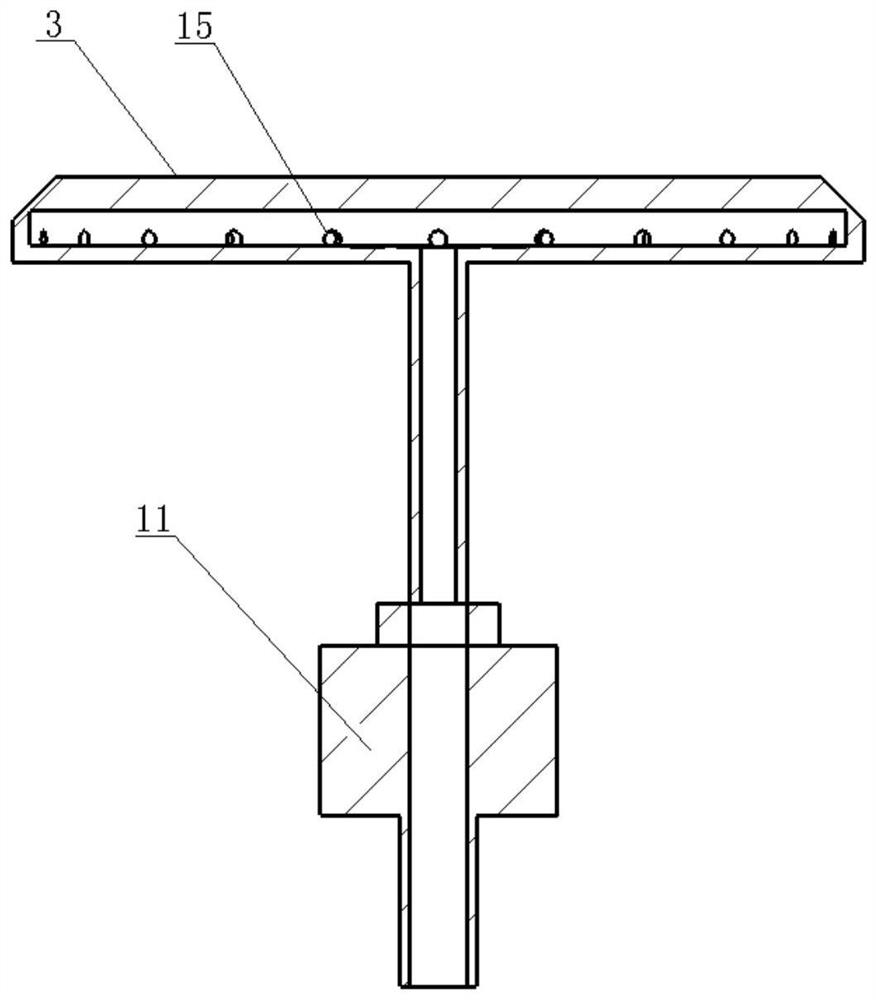

[0032] Such as figure 1 As shown, it includes a coaxially placed cathode 1 and a yoke base 7, an inner magnetic pole 3, an inner shield 9, an inner magnetic steel 10, an outer magnetic steel 6, an outer shield 12, and an insulating connection between the cathode 1 and the yoke base 7 Water-cooled anode 4;

[0033] Wherein, the bottom of the cathode 1 is processed with an installation groove for installing the insulator 8 and the water-cooled anode 4;

[0034] The yoke base 7 is located in the catho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com