Testing apparatus and testing method of thermoelectric conversion efficiency of thermoelectric module group

A technology of thermoelectric module and thermoelectric conversion, which is applied in the direction of measuring devices, measuring electricity, and measuring electrical variables, etc., can solve the problems of inaccurate measurement, complicated use, high cost, etc., and achieve the effect of economical and practical, simple device structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

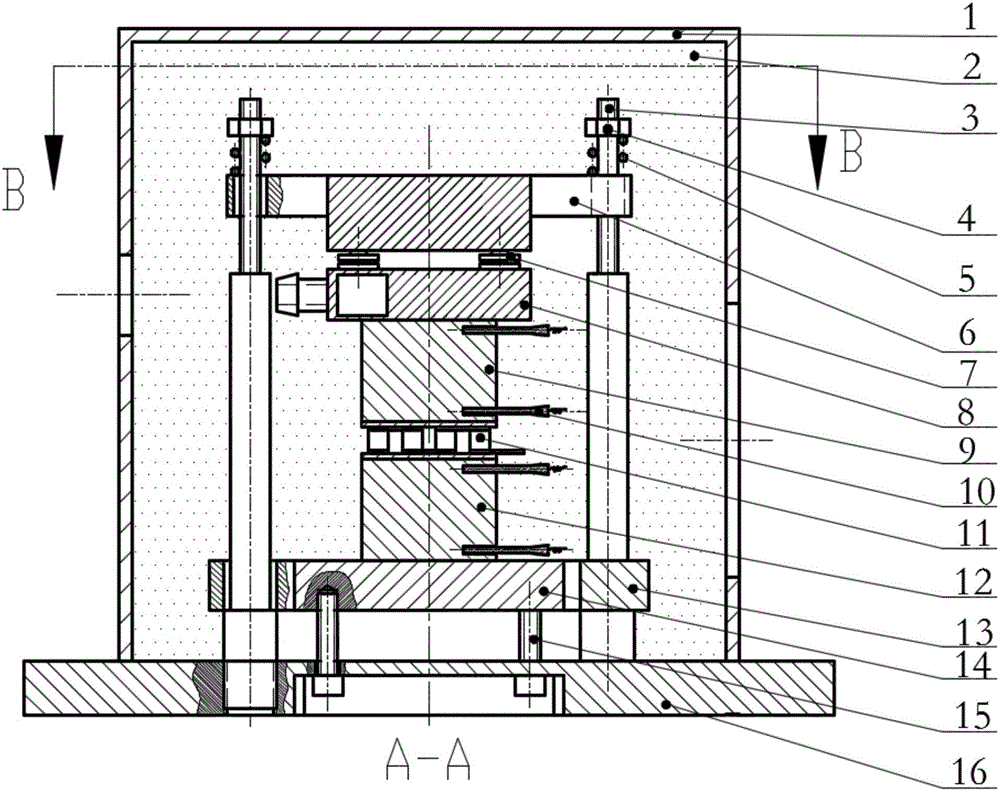

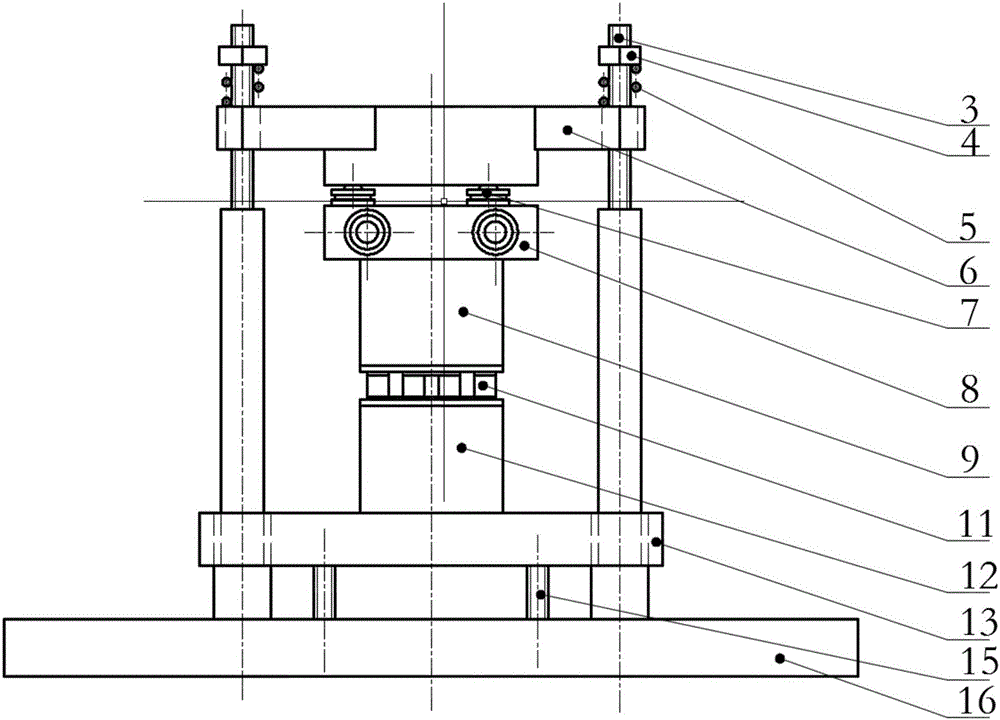

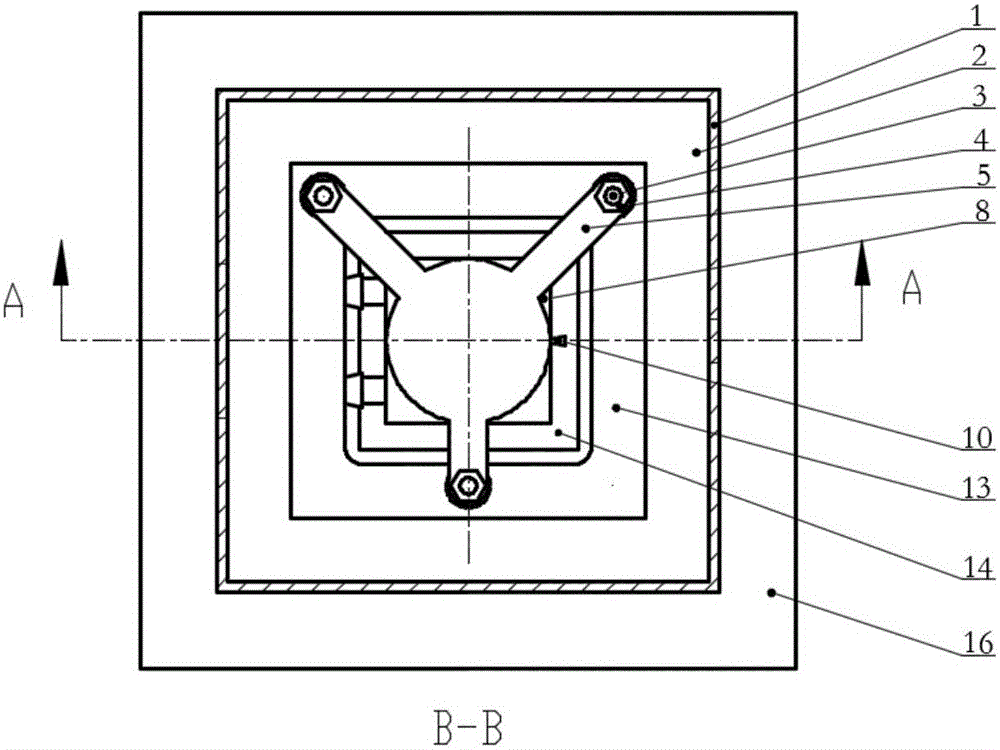

[0046] Such as figure 1 , figure 2 , image 3 As shown, the present invention includes an outer cover 1, a heat insulating material 2, a support rod 3, a compression nut 4, a spring 5, a compression block 6, a pressure sensor 7, a water cooling head 8, an upper standard measurement block 9, an armored thermocouple 10, Thermoelectric module 11 , lower standard measurement block 12 , heating platform protection fence 13 , electric heating platform 14 , supporting screws 15 and base plate 16 .

[0047] Three sets of support rods 3 are fixed on the base plate 16 through threaded connection, and the heating platform protection bar 13, pressing block 6, spring 5, and pressing nut 4 are arranged in sequence; the electric heating platform 14 is supported on the On the bottom plate 16, the heating platform protection fence 13 around the el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com