Copper-sulfur-based high-performance thermoelectric material and preparation method thereof

A technology of thermoelectricity and raw materials, which is applied in the direction of thermoelectric device node lead-out materials, thermoelectric device manufacturing/processing, etc., can solve the problems of low thermal conductivity value and inability to have thermoelectric performance, and achieve low thermal conductivity and good thermoelectric application prospects , good controllability and repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

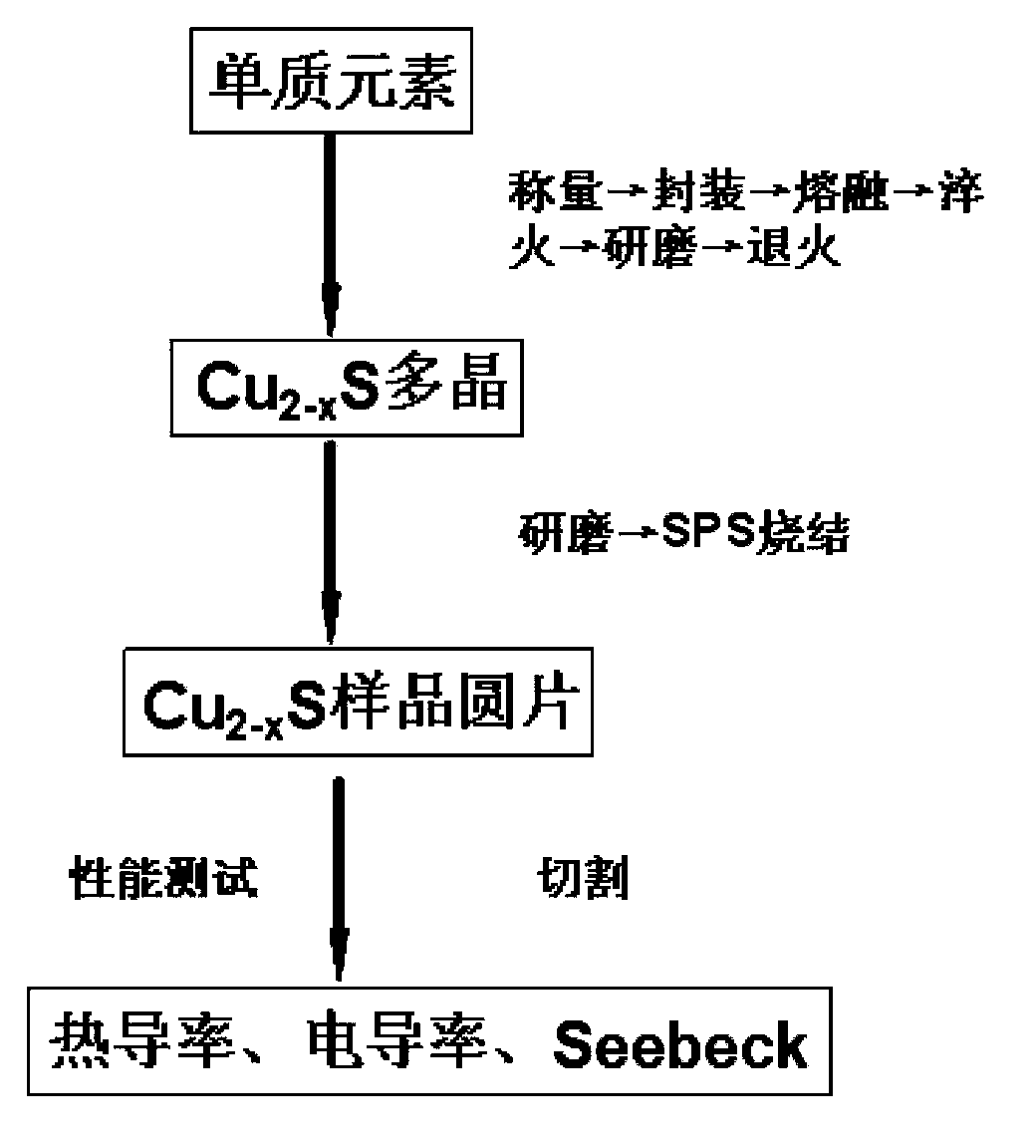

[0049] ●The preparation process of the present invention is realized through vacuum packaging, melting, quenching and annealing processes, figure 1 A process flow diagram for the preparation of this material is shown.

[0050] ●The preparation method of the present invention uses pure elements as initial raw materials, which are respectively simple copper, sublimed sulfur and simple Se / Te. The starting materials were weighed in the stoichiometric ratio (2-x):1-y:y and sealed in quartz tubes.

[0051] ●Vacuum packaging is carried out in an argon atmosphere glove box, using plasma or flame gun packaging, the quartz tube is vacuumed during packaging, and the internal pressure is 1-10000Pa.

[0052] ●The melting process is carried out in a vertical melting furnace. Heat up to 1150°C at a heating rate of 4.5°C / min, melt at a constant temperature for 20 hours, and then quench in an ice-water mixture.

[0053] ●The annealing process is carried out in a tubular annealing furnace. ...

Embodiment 1

[0056] Cu 1.88 S (x=0.02,y=0)

[0057] The elemental raw materials Cu and S were weighed at a molar ratio of 1.98:1, and then packaged in a quartz tube. The temperature was raised to 1150°C at a heating rate of 4.5°C / min, and the raw material was melted at 1150°C for 20 hours, and then quenched in a mixture of ice and water. The block obtained after quenching was ground into powder in an agate mortar, the powder was cold-pressed into a block, packaged in a quartz tube again, and finally put into a tube furnace and annealed at 580°C for 7 days, and then followed Furnace cool to room temperature.

[0058] The product obtained after annealing is ground into powder and subjected to spark plasma sintering (SPS sintering). The sintering temperature is 390-420°C, the pressure is 50 or 65MPa, and the sintering time is 5-10 minutes, and finally a dense bulk material is obtained.

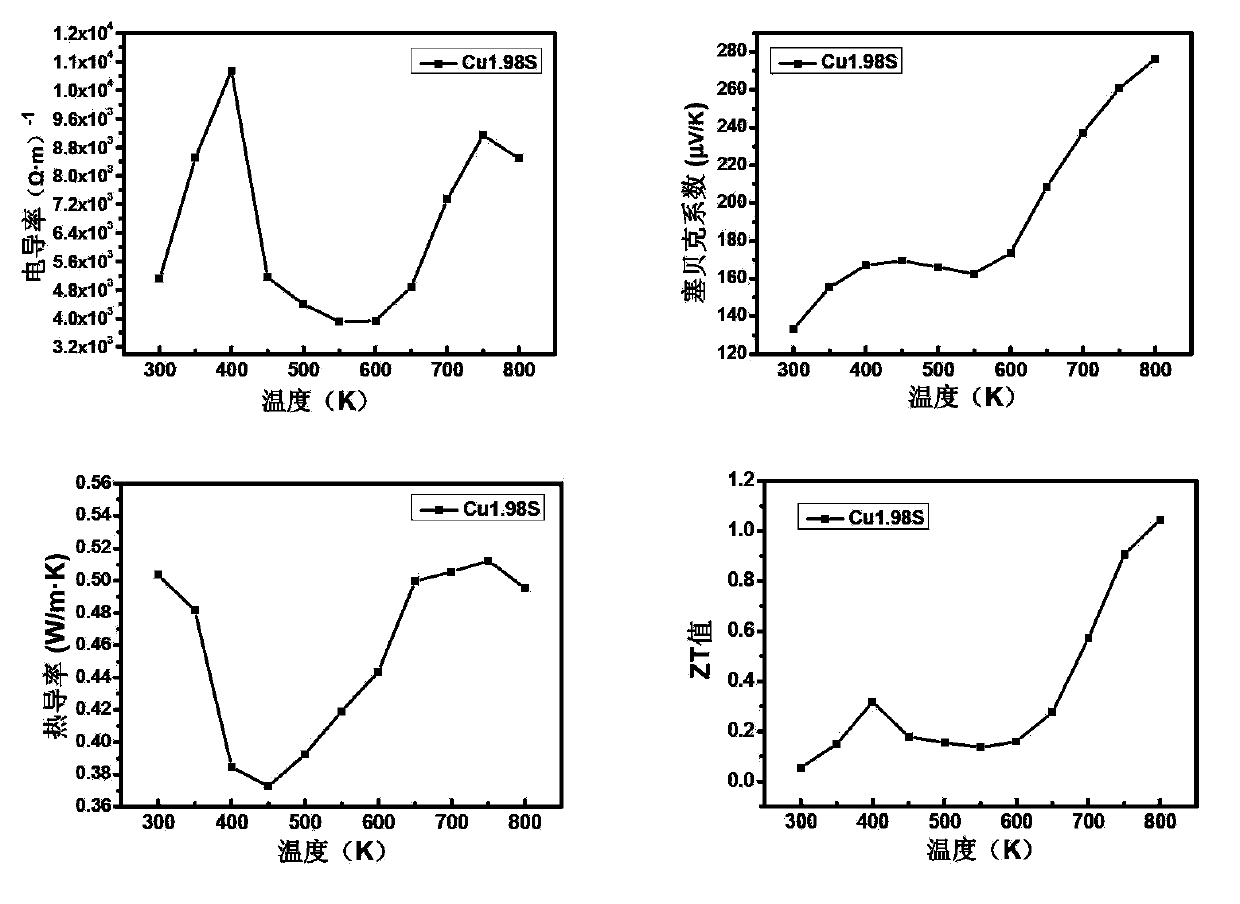

[0059] Such as figure 2 As shown, the resulting Cu 1.98 The measurement of thermoelectric properties...

Embodiment 2

[0061] Cu 1.95 S(x=005,y=0)

[0062] The elemental raw materials Cu and S were weighed at a molar ratio of 1.95:1, and then packaged in a quartz tube. The temperature was raised to 1150°C at a heating rate of 4.5°C / min, and the raw material was melted at 1150°C for 20 hours, and then quenched in a mixture of ice and water. The block obtained after quenching was ground into powder in an agate mortar, the powder was cold-pressed into a block, packaged in a quartz tube again, and finally put into a tube furnace and annealed at 580°C for 7 days, and then followed Furnace cool to room temperature.

[0063] The product obtained after annealing is ground into powder, and subjected to spark plasma sintering at a sintering temperature of 390-420° C., a pressure of 65 MPa, and a sintering time of 5-10 minutes to obtain a dense bulk material.

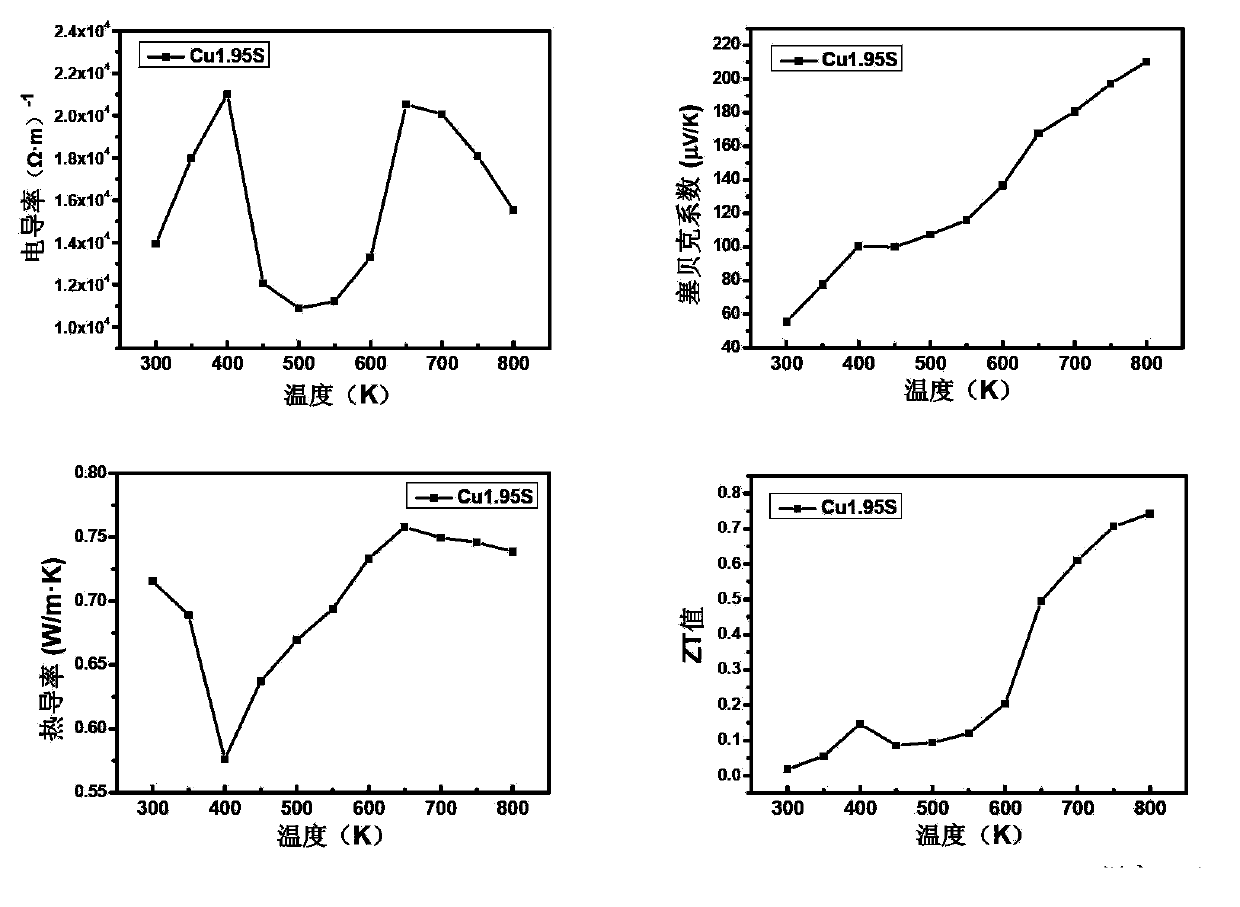

[0064] Such as image 3 As shown, the resulting Cu 1.95 Measurements of the thermoelectric properties of S bulk materials show that the Seeb...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thermoelectric figure of merit | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com