Thermoelectric performance measuring device and measuring method of thermoelectric refrigeration chip

A technology of thermoelectric refrigeration sheet and thermoelectric performance, which is applied in the direction of measurement device, measurement of electricity, measurement of electric variables, etc., can solve the problems of complex structure and low efficiency, and achieve the effects of high measurement accuracy, simple test process and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

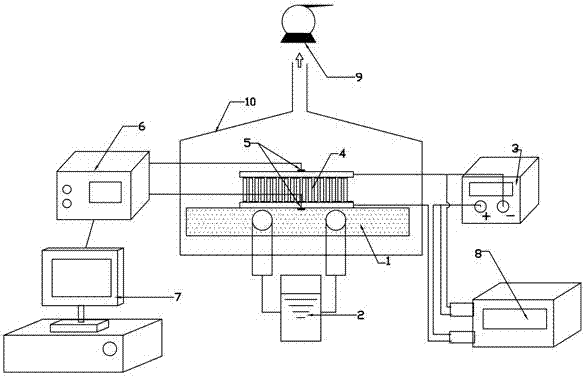

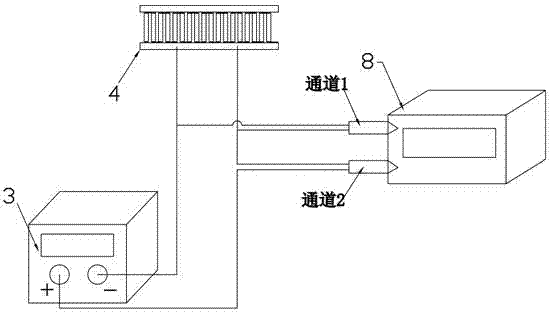

[0019] like figure 1 As shown, a test device for thermoelectric performance parameters of a thermoelectric cooling chip, including a water-cooled radiator 1, a constant temperature bath 2, a DC stabilized voltage and current power supply 3, a thermoelectric cooling chip 4, a platinum resistor 5, a data acquisition instrument 6, a computer 7, A multi-channel electrical parameter measuring instrument 8, a vacuum pump 9 and a vacuum cover 10. The hot end surface of the thermoelectric cooling sheet 4 is pasted on the water-cooled radiator 1, and the water-cooling radiator 1 is connected to the constant temperature bath 2 for cold and heat exchange, which is used to control the temperature of the hot end of the thermoelectric cooling sheet 4. The DC stabilized voltage and current power supply 3 is connected to the two poles of the thermoelectric cooling sheet 4, and the working voltage input to the thermoelectric cooling sheet 4 can be adjusted. Two platinum resistors are attached...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com