Preparation method of carbon-coated core-shell structure bismuth telluride nanorod, prepared carbon-coated core-shell structure bismuth telluride nanorod and application

A core-shell structure, bismuth telluride technology, applied in the field of nanometer bismuth telluride, can solve the problem of less carbon-encapsulated telluride, and achieve the effects of low production cost, simple post-processing, and good uniformity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

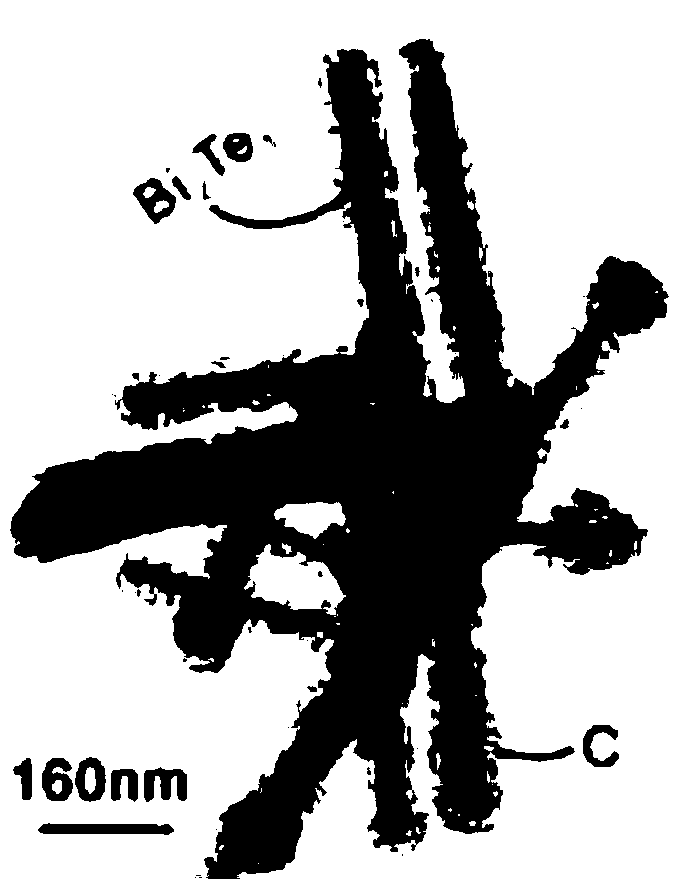

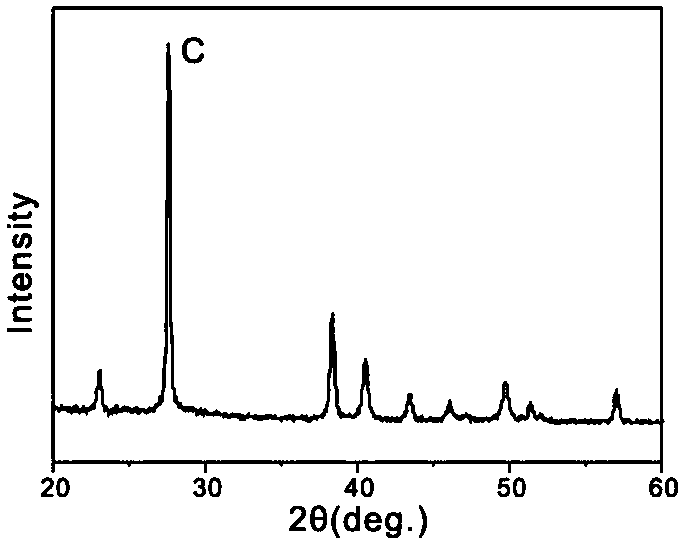

[0027] A method for preparing bismuth telluride nanorods with a carbon-wrapped core-shell structure, the steps of the method include:

[0028] S1. Add 48.5 mg of bismuth nitrate pentahydrate into 15 ml of deionized water and dissolve to obtain a bismuth ion solution;

[0029] S2. Add 22 mg of sodium tellurite into the bismuth ion solution, and stir magnetically for 40 minutes to obtain a turbid solution;

[0030] S3. Add 0.1 g of ascorbic acid into the turbid solution, and magnetically stir for 40 minutes to obtain a mixed solution a;

[0031] S4. Add 0.3 g of polyvinylpyrrolidone to the mixed solution a, and magnetically stir for 40 minutes to obtain the mixed solution b;

[0032] S5. Add dropwise 5ml of ethylene glycol solution to the mixed solution b, and magnetically stir to obtain the mixed solution c;

[0033] S6. Transfer the mixed solution c to a reactor for hydrothermal reaction to obtain bismuth telluride nanorods with a carbon-wrapped core-shell structure; specifi...

Embodiment 2

[0039] A method for preparing bismuth telluride nanorods with a carbon-wrapped core-shell structure, the steps of the method include:

[0040] S1, 97mg of bismuth nitrate pentahydrate was added into 15ml of deionized water and dissolved to obtain a bismuth ion solution;

[0041] S2. Add 22 mg of sodium tellurite into the bismuth ion solution, and stir magnetically for 40 minutes to obtain a turbid solution;

[0042] S3. Add 0.1 g of ascorbic acid into the turbid solution, and magnetically stir for 40 minutes to obtain a mixed solution a;

[0043] S4. Add 0.3 g of polyvinylpyrrolidone to the mixed solution a, and magnetically stir for 40 minutes to obtain the mixed solution b;

[0044] S5. Add dropwise 5ml of ethylene glycol solution to the mixed solution b, and magnetically stir for 2 minutes to obtain the mixed solution c;

[0045] S6. Transfer the mixed solution c to a reactor for hydrothermal reaction to obtain bismuth telluride nanorods with a carbon-wrapped core-shell s...

Embodiment 3

[0050] A method for preparing bismuth telluride nanorods with a carbon-wrapped core-shell structure, the steps of the method include:

[0051] S1, adding 31.5 mg of bismuth chloride into 15 ml of deionized water and dissolving it to obtain a bismuth ion solution;

[0052]S2. Add 44 mg of sodium tellurite into the bismuth ion solution, and stir magnetically for 40 minutes to obtain a turbid solution;

[0053] S3. Add 0.1 g of ascorbic acid into the turbid solution, and magnetically stir for 40 minutes to obtain a mixed solution a;

[0054] S4. Add 0.2 g of polyvinylpyrrolidone to the mixed solution a, and magnetically stir for 40 minutes to obtain the mixed solution b;

[0055] S5. Add dropwise 5ml of ethylene glycol solution to the mixed solution b, and magnetically stir for 2 minutes to obtain the mixed solution c;

[0056] S6. Transfer the mixed solution c to a reactor for hydrothermal reaction to obtain bismuth telluride nanorods with a carbon-wrapped core-shell structure...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com