Two-dimensional nickel telluride supported palladium monatomic catalyst as well as preparation method and application thereof

A technology of nickel telluride and catalyst, which is applied in the field of two-dimensional nickel telluride-supported palladium single atom catalyst and its preparation, which can solve the problems of limited production of noble metal-based catalysts, easy agglomeration of noble metals, and reduced catalytic activity, so as to improve the Pd Atom utilization rate and charge transfer ability, solve environmental pollution, solve the effect of low efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Example 1 Ni(OH) 2 Precursor preparation

[0040] 0.34g of nickel nitrate hexahydrate, 0.074g of ammonium fluoride and 0.3g of urea were dissolved in 30mL of deionized water and stirred for 30min; placed in a 50mL hydrothermal reaction kettle, hydrothermally reacted at 120°C for 6h, filtered and deionized with Washed with water and ethanol, dried at 60°C for 12h to obtain nanosheet Ni(OH) 2 Precursor.

Embodiment 2

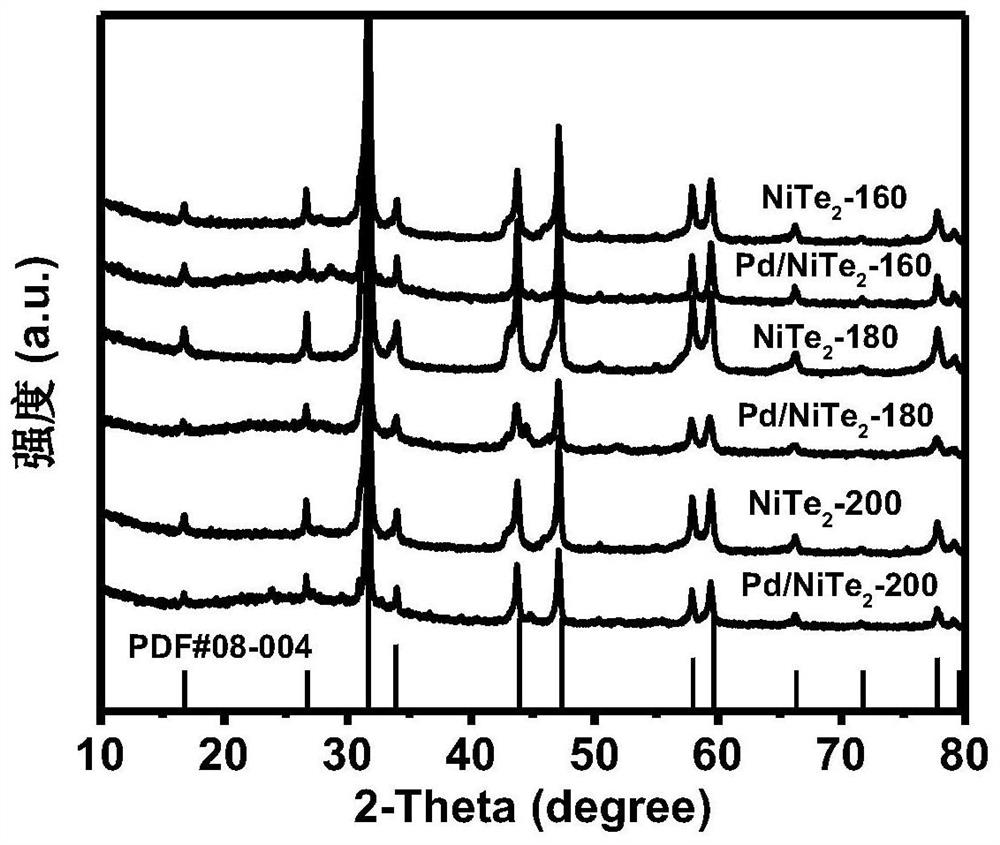

[0041] Example 2 NiTe 2 -160 and Pd / NiTe 2 Preparation of -160

[0042] (1) get the Ni(OH) prepared by embodiment 1 2 Disperse 0.2g of precursor, 0.442g of sodium tellurite and 3mL of hydrazine hydrate into 37mL of deionized water and stir for 1h; put it into a 50mL hydrothermal reactor, react at 160°C for 6h, filter the product, and wash it with deionized water and ethanol , dried at 60°C for 12h to obtain two-dimensional nickel telluride nanosheets, denoted as NiTe 2 -160.

[0043] (2) Take 0.1g of the two-dimensional nickel telluride nanosheet NiTe prepared in step (1) 2 Disperse -160 and 1mg potassium chloropalladate in 1mL deionized water, sonicate for 30min, stir for 1h, heat and evaporate to dryness, remove water; 2 Under the protection of atmosphere, annealing and heat treatment for 2h, and then the obtained solid sample was washed with 0.1M HCl to remove impurity potassium oxide, and the catalyst Pd / NiTe with two-dimensional nickel telluride supporting palladium ...

Embodiment 3

[0044] Example 3 NiTe 2 -180 and Pd / NiTe 2 Preparation of -180

[0045] According to the method of Example 2, the reaction temperature of step (1) was adjusted to 180°C to obtain two-dimensional nickel telluride nanosheets, which were denoted as NiTe 2 -180; Potassium chloropalladate in step (2) is 2mg, obtains catalyst Pd / NiTe 2 -160.

PUM

| Property | Measurement | Unit |

|---|---|---|

| electric potential / voltage | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com