Tellurium nano-particles and preparation method for same

A technology of tellurium nanoparticles and particles, which is applied in the field of tellurium nanoparticles and its preparation, can solve the problems of failing to obtain zero-dimensional tellurium nanostructures, and achieve the effects of large specific surface area, scientific preparation method, and less raw materials

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] The concrete steps of preparation are:

[0022] In step 1, sodium tellurite is first added into water, and stirred until completely dissolved to obtain an aqueous solution of sodium tellurite; wherein, the water is deionized water. Add glutathione to the sodium tellurite aqueous solution and stir for 1 d to obtain a reaction solution; wherein the weight ratio of sodium tellurite, glutathione and water in the reaction solution is 7:5:2000.

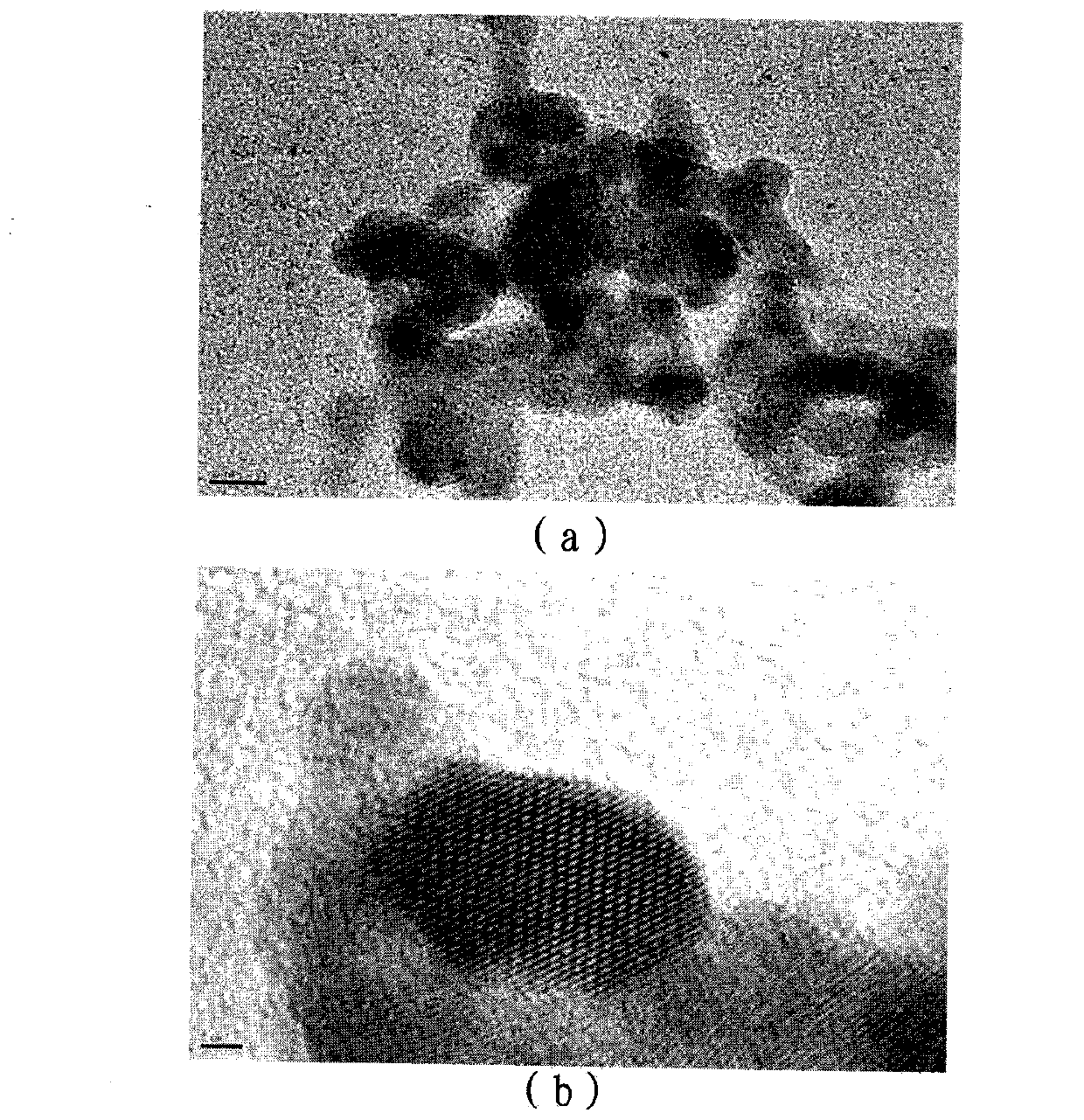

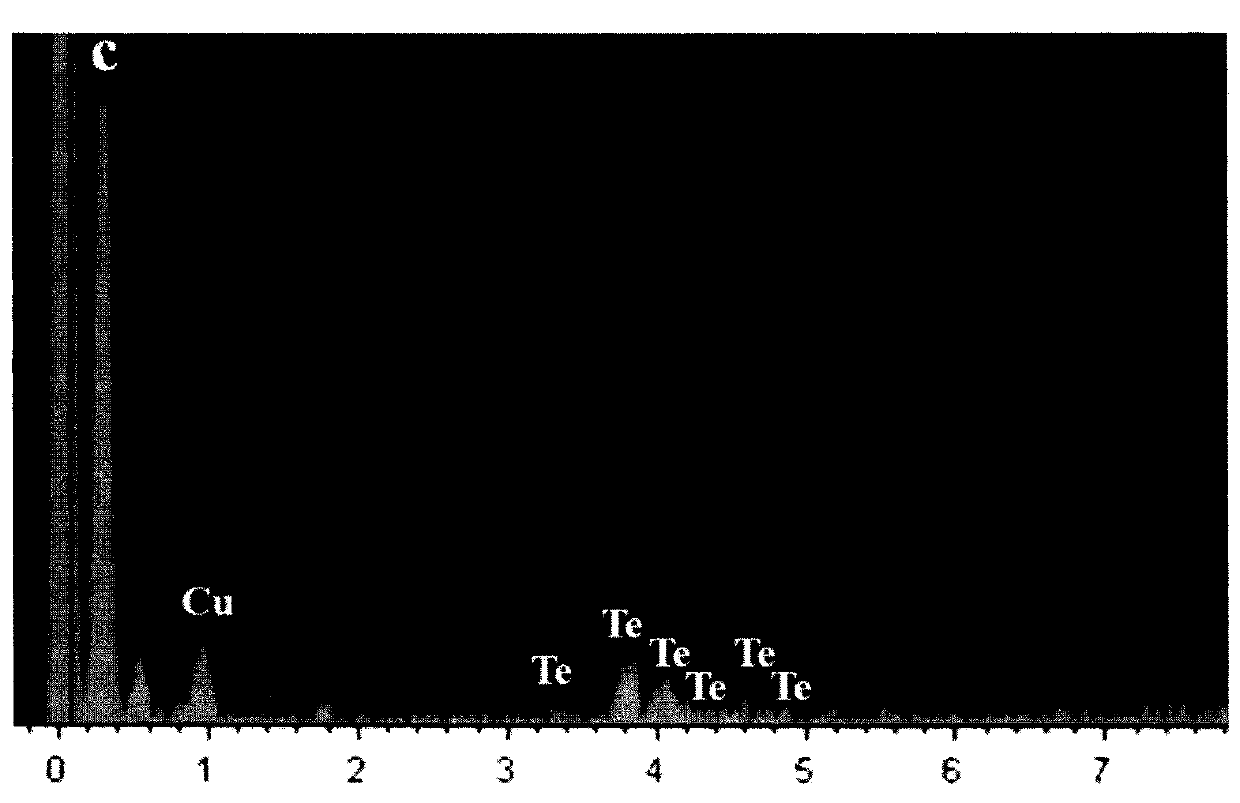

[0023] In step 2, the reaction solution is subjected to solid-liquid separation treatment; wherein, the solid-liquid separation treatment is centrifugation, and the centrifugation speed is 5000r / min and the time is 10min. The solid matter obtained after separation is then subjected to cleaning treatment; wherein, the cleaning treatment is to sequentially wash and centrifuge the solid matter once, and the washing is to use deionized water to wash. made approximately figure 1 shown, and as figure 2 Tellurium nanoparticles shown in ...

Embodiment 2

[0025] The concrete steps of preparation are:

[0026] In step 1, sodium tellurite is first added into water, and stirred until it is completely dissolved to obtain an aqueous solution of sodium tellurite; wherein, the water is distilled water. Add glutathione to the sodium tellurite aqueous solution and stir for 1.5 days to obtain a reaction solution; wherein, the weight ratio of sodium tellurite, glutathione and water in the reaction solution is 8:4.5:2000.

[0027] In step 2, the reaction liquid is first subjected to solid-liquid separation treatment; wherein, the solid-liquid separation treatment is centrifugation, and the centrifugation speed during centrifugation is 6000r / min and the time is 9min. The solid matter obtained after separation is then cleaned; wherein, the cleaning process is to wash and centrifuge the solid matter twice in sequence, and the washing is to use deionized water to wash. made approximately figure 1 shown, and as figure 2 Tellurium nanopartic...

Embodiment 3

[0029] The concrete steps of preparation are:

[0030] In step 1, sodium tellurite is first added into water, and stirred until completely dissolved to obtain an aqueous solution of sodium tellurite; wherein, the water is deionized water. Add glutathione to the sodium tellurite aqueous solution and stir for 2 days to obtain a reaction liquid; wherein, the weight ratio of sodium tellurite, glutathione and water in the reaction liquid is 9:4:2000.

[0031] In step 2, the reaction liquid is subjected to solid-liquid separation treatment; wherein, the solid-liquid separation treatment is centrifugation, and the centrifugation speed is 7000r / min, and the centrifugation time is 9min. The solid matter obtained after separation is then cleaned; wherein, the cleaning process is to wash and centrifuge the solid matter twice in sequence, and the washing is to use deionized water to wash. made as figure 1 shown, and as figure 2 Tellurium nanoparticles shown in the curve.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com