Bismuth base hydrogen storage material and preparation method thereof

A hydrogen storage material, bismuth-based technology, applied in bismuth selenide, bismuth-based hydrogen storage material and its preparation, bismuth telluride layered compound, hydrogen storage, preparation, application field of lithium storage and electrode materials, and methods to achieve Low temperature, good dispersion and good crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

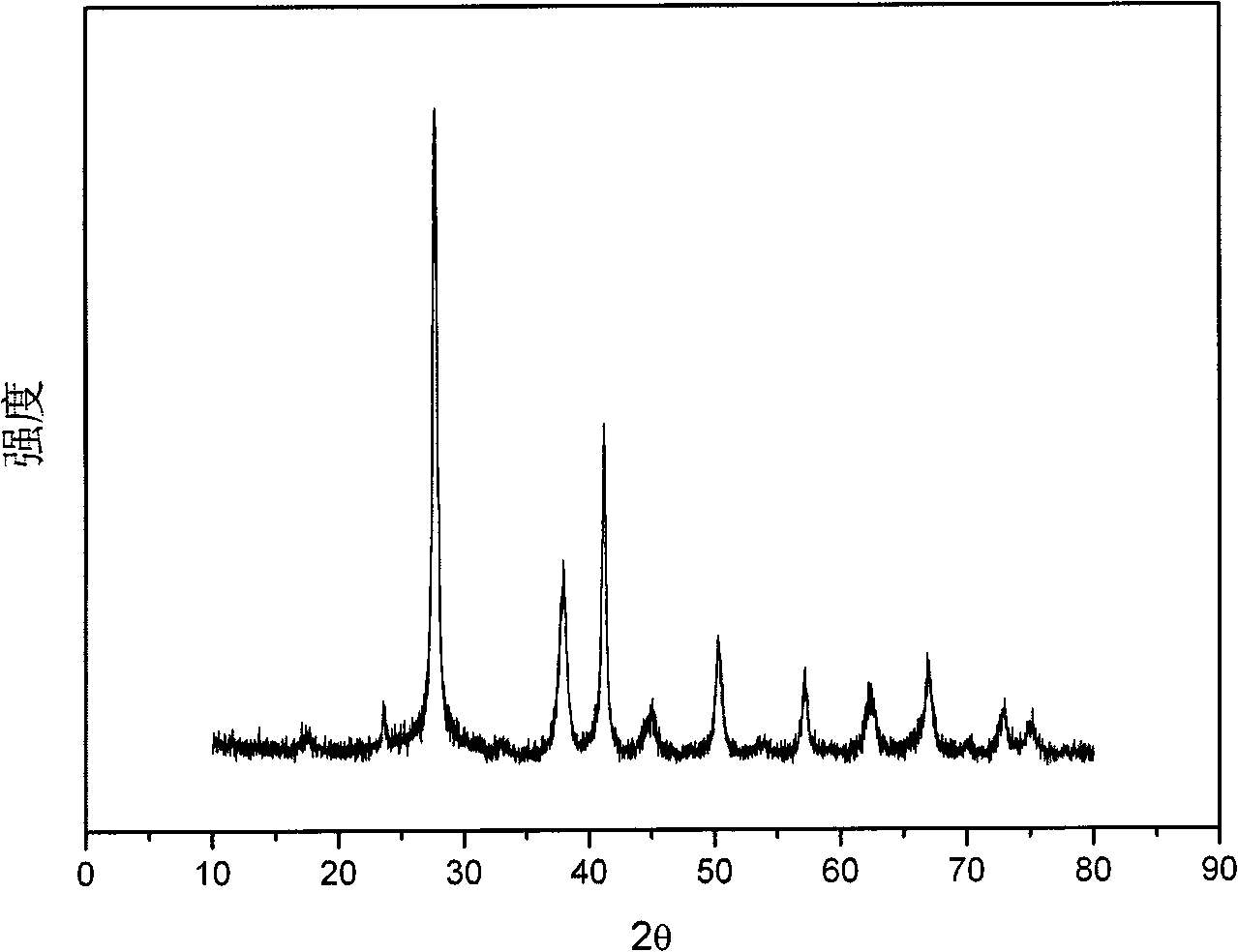

[0032] At room temperature, take 2mL 0.1m / l Bi(NO 3 ) 3 , 10mL 0.1m / L NTA (nitrilotriacetic acid), 3mL 0.1m / l Na 2 TeO 3 , 10mL 0.5m / l vitamin C is placed in a 50mL container, after mixing evenly, adjust the pH to 10 with ammonia water, and seal the container mouth with a polyethylene film to prevent solvent water from evaporating. Place the sealed container in a water bath at 70°C, keep it warm for 1 hour, cool the container to room temperature naturally, take out the product, centrifuge the product, and wash the separated product twice with ethanol and distilled water respectively. Vacuum drying at 50°C to obtain flaky bismuth telluride. figure 1 In the X-ray diffraction spectrum of the bismuth telluride nanosheets prepared for this example, no diffraction peaks of any impurities are found in the spectrum, indicating that the product is single-phase bismuth telluride nanosheets.

Embodiment 2

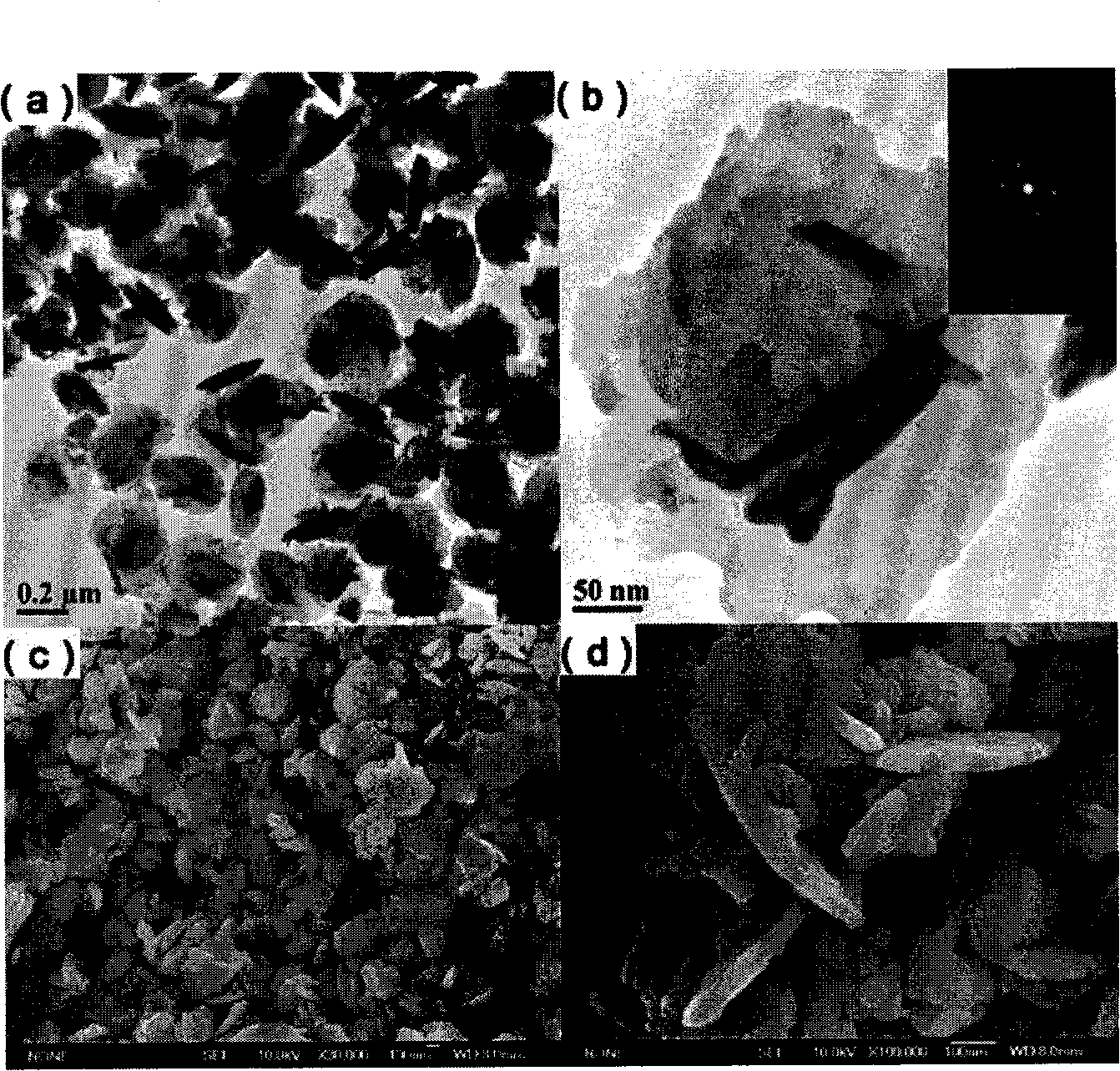

[0034] At room temperature, take 2mL 0.1m / l Bi(NO 3 ) 3 , 10mL 0.1m / L NTA, 3mL 0.1m / lNa 2 TeO 3 , 10mL 0.5m / l vitamin C is placed in a 50mL container, after mixing evenly, adjust the pH to 12 with ammonia water, and seal the container mouth with a polyethylene film to prevent solvent water from evaporating. Place the sealed container in a water bath at 70°C, keep it warm for 0.5 hours, cool the container to room temperature naturally, take out the product, centrifuge the product, and wash the separated product twice with ethanol and distilled water respectively. Vacuum drying at 50°C to obtain flaky bismuth telluride. figure 2 For SEM and TEM photos, it can be seen from the photos that the prepared Bi 2 Te 3 The nanosheets have a diameter of 200-300nm and a thickness of 30nm.

Embodiment 3

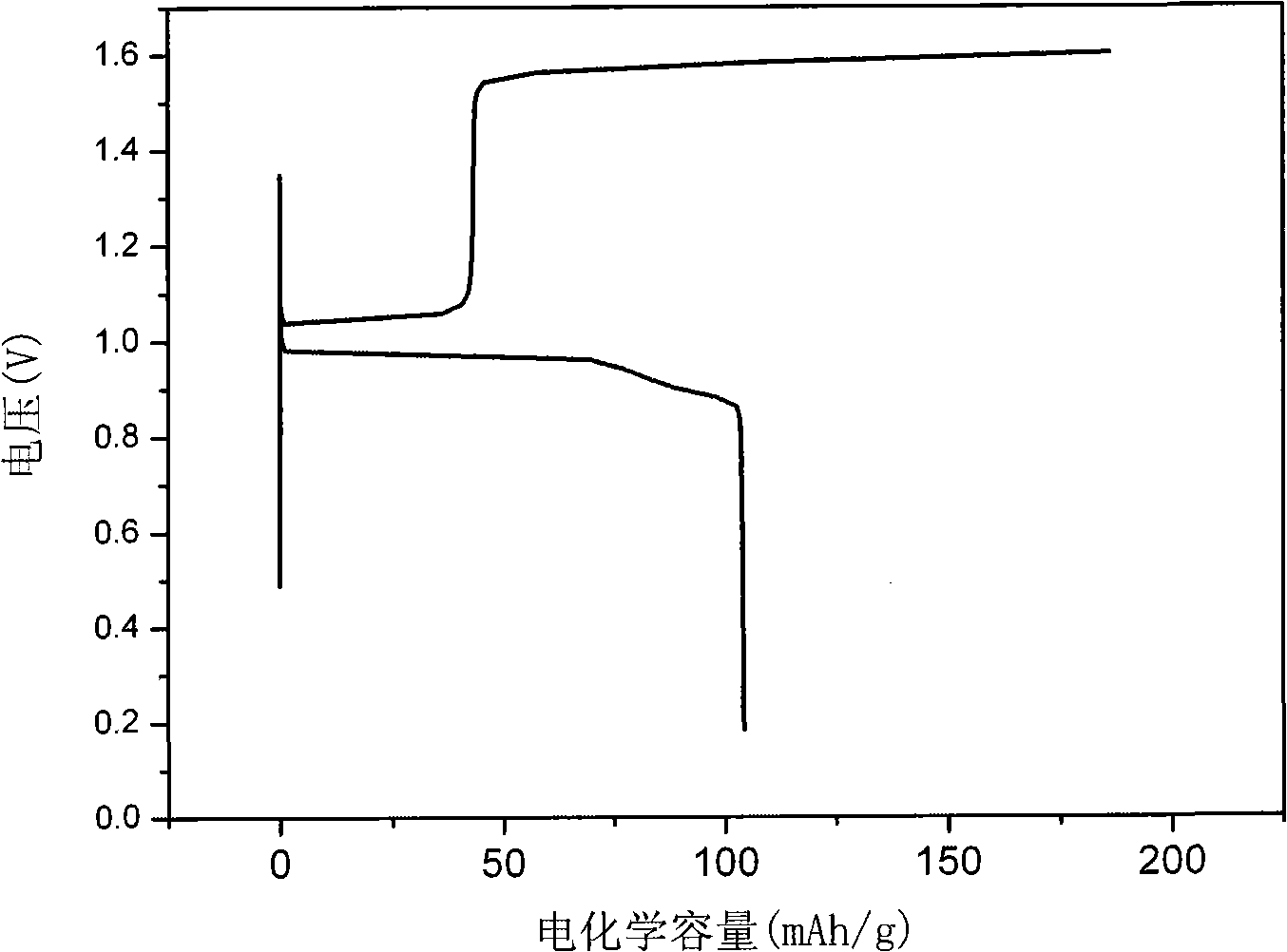

[0036] At room temperature, sequentially take 2mL of 0.1m / l BiCl 3 , 10mL 0.1m / L EDTA (hexanediaminetetraacetic acid), 3mL 0.1m / l Na 2 TeO 3 , 1mL 0.01m / l sodium borohydride is placed in a 50mL container, after mixing evenly, adjust the pH to 10 with ammonia water, and seal the container mouth with a polyethylene film to prevent the evaporation of solvent water. Place the sealed container in a water bath at 70°C, keep it warm for 1 hour, cool the container to room temperature naturally, take out the product, centrifuge the product, and wash the separated product twice with ethanol and distilled water respectively. Vacuum drying at 50°C to obtain flaky bismuth telluride. The synthesized bismuth telluride nanosheets were directly pressed into nickel foil, and their electrochemical properties were characterized by DT-5 electrical performance testing system. image 3 The electrochemical charge and discharge curves of the bismuth telluride nanosheets prepared for this example ca...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com