Method for separating tellurium from tellurium slag

A technology for tellurium slag and tellurium powder, which is applied in the field of hydrometallurgy for separating tellurium, can solve problems such as inability to directly recycle, and achieve the effects of short processing time, reduction of the amount of returned slag, and small transformation range.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

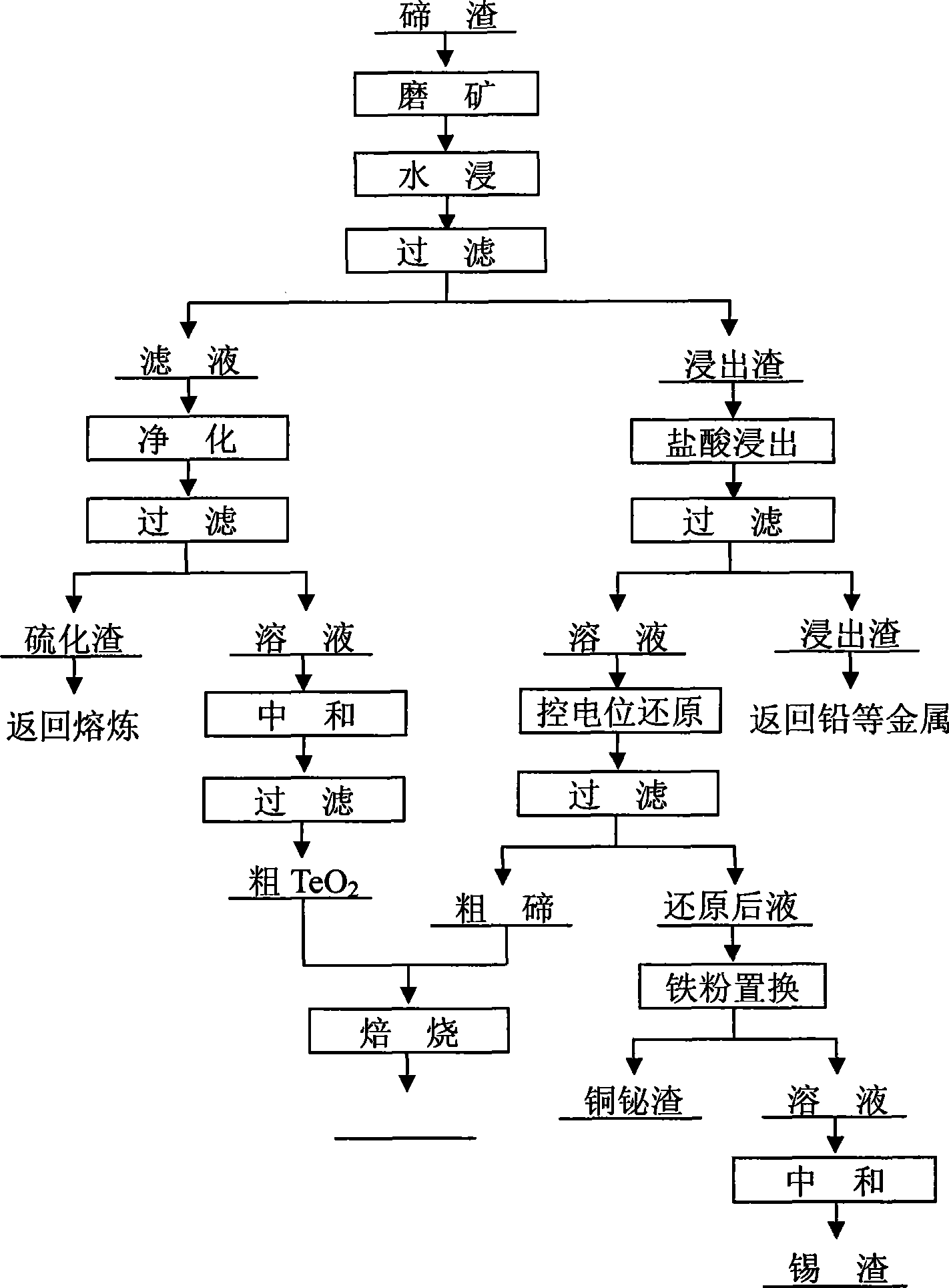

Image

Examples

Embodiment 1

[0034] Example 1: Take 1000 g of tellurium slag produced in the copper smelting process containing Te 8.5%, Se 0.45%, Cu 9.6%, and Bi 12%, and grind it until the particle size is 100% less than 0.074mm. After leaching for 3 hours under the conditions of 3:1 and stirring speed of 150r / min, it was filtered. The volume of the water immersion liquid was 3.1L, and the composition (g / L): Te 13.2, Se 0.58; the weight of the water leaching residue was 720g after drying, containing Tellurium is 6.14%, and the leaching rate of tellurium slag is 48.0%. Heat the water immersion solution to 80°C, add 6.8g sodium sulfide and 16g calcium chloride, continue to stir for 1 hour, then filter, and neutralize the purified solution with 3mol / L sulfuric acid solution until pH = 5, continue to stir for 2 hours, and then filter to produce The obtained crude tellurium dioxide weighs 53 g after drying and contains 76.0% tellurium.

[0035] The water leaching residue was stirred and leached in a hydroch...

Embodiment 2

[0037]Example 2: Take 500g of tellurium slag produced in the bismuth smelting and smelting process containing Te 36%, Se 0.6%, Cu 6%, and Bi 24%, and grind it until the particle size is 100% less than 0.074mm. Ratio 3:1, stirring speed 150r / min under the conditions of leaching for 4h and then filtering, the volume of the water immersion liquid is 1.6L, the composition (g / L): Te57.37, Se0.75; the weight of the water leaching residue after drying is 350g, containing 25.2% tellurium, the leaching rate of tellurium slag is 51.0%. Heat the water immersion solution to 80°C, add 4.8g sodium sulfide and 10g calcium chloride, continue to stir for 1 hour, then filter, and neutralize the purified solution with 4mol / L sulfuric acid solution until pH = 5, continue to stir for 2 hours, and then filter to produce The crude tellurium dioxide produced weighs 120 g after drying and contains 76.5% tellurium.

[0038] The water leaching residue was stirred and leached in a hydrochloric acid solu...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com