Method for extracting tellurium from tellurium copper slags

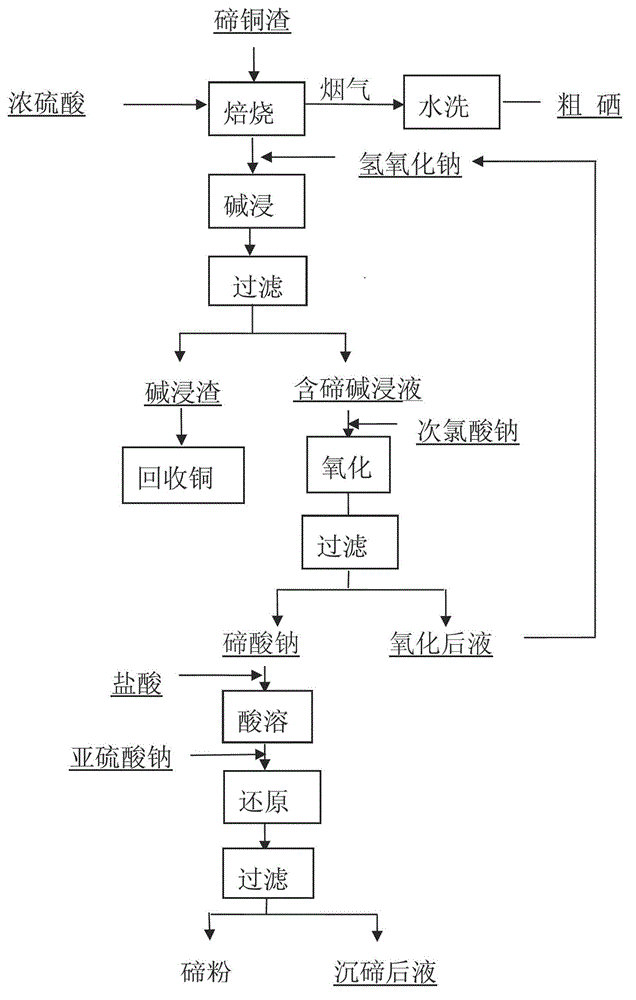

A tellurium copper and slag grinding technology is applied in the field of extracting tellurium, which can solve the problems of low leaching rate, large consumption of chemicals, and low recovery rate of tellurium, and achieve the effect of simple process and good effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0059] (1) High temperature sulfate roasting

[0060] Take 1 kg of tellurium-copper slag and grind it to 100 meshes. The composition of tellurium-copper slag: Te 20.34%, Cu 52.6%, Se 3.01%, As 0.64%, Bi 0.12%, Sb 0.07%, add 1.3kg of concentrated sulfuric acid and stir evenly, start Roasting operation, the roasting temperature is 500°C, the roasting time is 4 hours, after cooling, 1.28kg of calcined sand is obtained, and the calcined sand is ground to 100 mesh. The main components of the calcined sand are: Te 15.87%, Cu 41.09%, Se 0.51%, As 0.48% , Bi 0.05%, Sb 0.02%. The flue gas produced in the roasting process is used to recover selenium through a water-washing spray tower, and the selenium content of crude selenium is 82%.

[0061] (2) Alkali leaching tellurium

[0062] Take 1.28 kg of calcined sand obtained in step (1), add sodium hydroxide with a concentration of 2 mol / L according to the liquid-solid ratio of 7:1, and leaching at a temperature of 80°C for 4 hours: filte...

Embodiment 2

[0068] (1) High temperature sulfate roasting

[0069] Take 1 kg of tellurium-copper slag and grind it to 110 meshes, the composition of tellurium-copper slag: Te 25.73%, Cu 46.66%, Se 2.65%, As 0.58%, Bi 0.11%, Sb 0.08% 1Kg, add 1.4kg of concentrated sulfuric acid and stir evenly, Start the roasting operation, the roasting temperature is 550°C, and the roasting time is 5 hours. After cooling, 1.32kg of calcined sand is obtained, and the calcined sand is ground to 120 mesh. The main components of the calcined sand are: Te 19.48%, Cu 35.32%, Se 0.46%, As 0.40 %, Bi 0.08%, Sb 0.03%. The flue gas produced in the roasting process is recycled through the water washing spray tower and the lye spray tower, and the selenium content of the crude selenium is 80%.

[0070] (2) Alkali leaching tellurium

[0071] Take 1.32 kg of calcined sand obtained in step (1), add sodium hydroxide with a concentration of 3 mol / L according to the liquid-solid ratio of 7:1, leaching at a temperature of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com