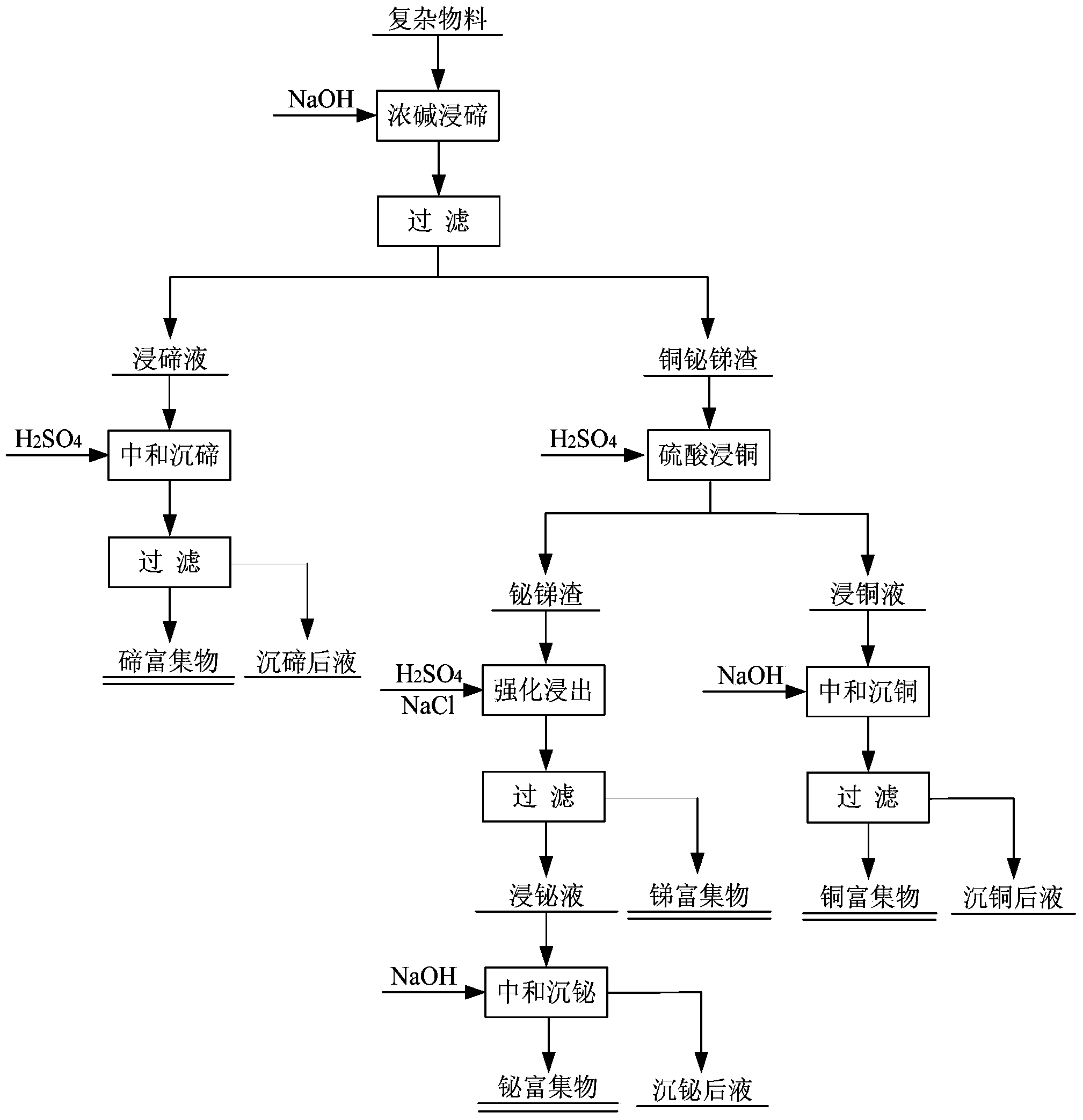

Method for recovering tellurium, bismuth, antimony, and copper from complex material

A material and complex technology, applied in the field of separation and enrichment of non-ferrous metals, which can solve problems such as comprehensive recovery of valuable metals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0036] The chemical composition of the complex material is Cu11.25%, As6.58%, Te6.71%, Bi23.54%, Sb14.56%, put into the reaction kettle at a solid-liquid ratio of 1:4, and then press 100g / L in the kettle Sodium hydroxide concentration was added to solid caustic soda. The solution was kept at a constant temperature of 85°C and stirred for 4 hours. The filter residue contains 0.51% tellurium, and the leaching rate of tellurium is 95.01%.

[0037] Dilute sulfuric acid was added to the tellurium bath to adjust the pH, and the pH value was kept at 5.0 at the end point. During the tellurium precipitation process, the temperature was maintained at 85°C by heating with a steam coil, and the stirring was continued for 1 hour after reaching the end point. After standing still, the liquid and solid are separated. After the tellurium is precipitated, the liquid contains only 115mg / L tellurium, and the tellurium enrichment contains 71.32% tellurium. It enters the refined tellurium produc...

Embodiment 2

[0043]The chemical composition of the complex material is Cu11.25%, As6.58%, Te6.71%, Bi23.54%, Sb14.56%, put it into the reaction kettle at a solid-liquid ratio of 1:8, and then press 150g / L in the kettle Sodium hydroxide concentration was added to solid caustic soda. The solution was kept at a constant temperature of 60°C and stirred for 7 hours. The filter residue contains 0.48% tellurium, and the leaching rate of tellurium is 95.12%.

[0044] Dilute sulfuric acid was added to the tellurium immersion solution to adjust the pH, and the pH value was kept at 5.5 at the end point. During the tellurium precipitation process, the temperature was maintained at 85°C by heating with a steam coil, and the stirring was continued for 1 hour after reaching the end point. Then stand still, liquid and solid are separated, the liquid contains only 153mg / L tellurium after tellurium precipitation, and the tellurium enrichment contains 71.65% tellurium.

[0045] Add copper, bismuth and ant...

Embodiment 3

[0050] The chemical composition of the complex material is Cu11.25%, As6.58%, Te6.71%, Bi23.54%, Sb14.56%, put into the reaction kettle at a solid-liquid ratio of 1:5, and then press 120g / L in the kettle Sodium hydroxide concentration was added to solid caustic soda. The solution was kept at a constant temperature of 90°C and stirred for 4 hours. The filter residue contains 0.45% tellurium, and the leaching rate of tellurium is 95.36%.

[0051] Dilute sulfuric acid was added to the tellurium immersion solution to adjust the pH, and the pH value was kept at 4.5 at the end point. During the tellurium precipitation process, the temperature was maintained at 85°C by heating with a steam coil, and the stirring was continued for 1 hour after reaching the end point. After standing still, the liquid and solid are separated, and the tellurium content of the liquid is only 109mg / L after the tellurium precipitation, and the tellurium enrichment contains 71.36% tellurium.

[0052] Add ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com