Method for recycling valuable metals from lead anode slime

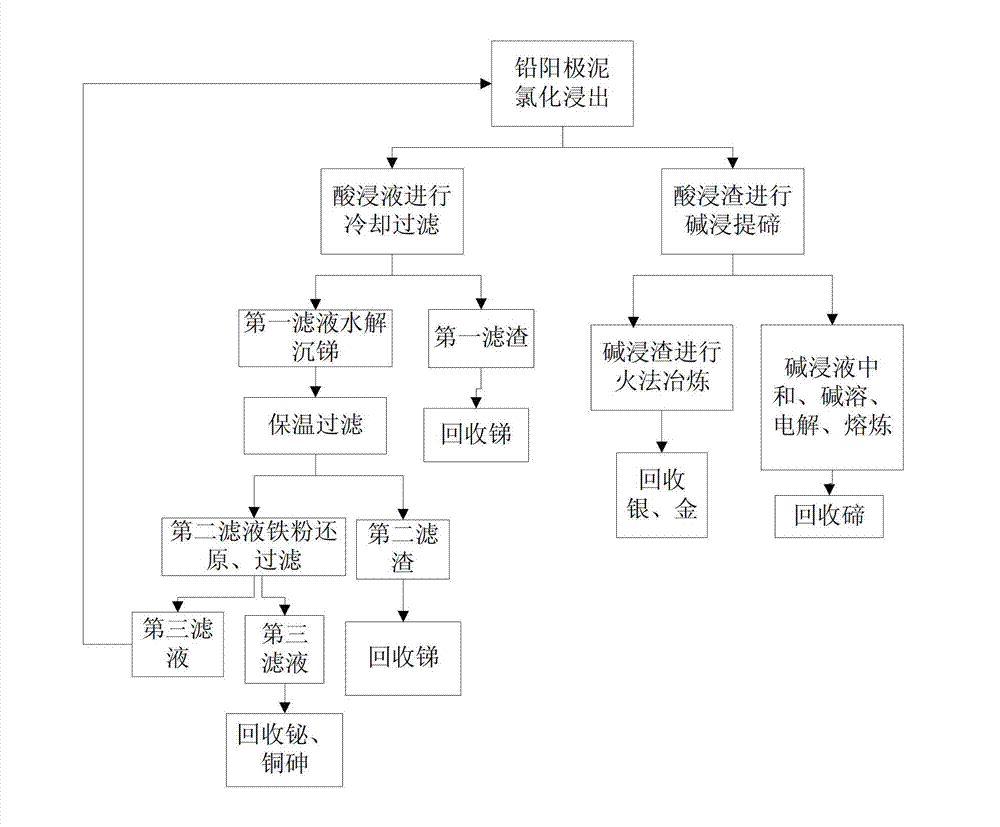

A valuable metal and lead anode slime technology is applied in the field of hydrometallurgy, which can solve the problems of difficult leaching of antimony and low yield of valuable metals, and achieve the effects of high recovery rate, reduced reagent consumption and simple process route.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] 1) Chlorinated acid leaching: Dry the anode slime at 80°C for 2 days and then grind it into a fine powder. The fine powder is oxidized naturally in the air for 9 days to obtain oxidized anode slime. Soak 78wt% oxidized anode slime, 17wt% sodium chloride, and 5wt% sodium chlorate in a strong acid solution with a solid-to-liquid volume ratio of 1:5 and a concentration of 6mol / L, stir at 80°C for 4 hours, and filter to obtain Pickling solution and pickling residue.

[0051] 2) Hydrolysis of Tellurium Precipitation: Cooling and crystallizing the acid leaching solution and filtering to obtain the first filter residue and the first filtrate; recover antimony from the first filter residue; add an equal amount of water to the first filtrate to dilute, and adjust the pH value with alkaline solution 2. Obtaining the hydrolyzate, carrying out the heat preservation and filtering step of the hydrolyzate to obtain the second filter residue and the second filtrate; and recovering the ...

Embodiment 2

[0056] 1) Chlorinated acid leaching: Dry the anode slime at 80°C for 2 days and then grind it into a fine powder, then place the fine powder in the air for natural oxidation for 3-9 days to obtain oxidized anode slime. Take 65wt% oxidized anode slime, 15wt% sodium chloride, and 20wt% sodium chlorate and soak them in a strong acid solution with a solid-to-liquid volume ratio of 1:10 and a concentration of 3mol / L, stir at 80°C for 4 hours, and filter to obtain Pickling solution and pickling residue.

[0057] 2) Hydrolysis of Tellurium Precipitation: Cooling and crystallizing the acid leaching solution and filtering to obtain the first filter residue and the first filtrate; recover antimony from the first filter residue; add an equal amount of water to the first filtrate to dilute, and adjust the pH value with alkaline solution 1. Obtaining a hydrolyzate, carrying out heat preservation and filtration on the hydrolyzate to obtain a second filter residue and a second filtrate; and ...

Embodiment 3

[0062] 1) Chlorinated acid leaching: Dry the anode slime at 80°C for 2 days and then grind it into a fine powder, then place the fine powder in the air for natural oxidation for 3-9 days to obtain oxidized anode slime. Soak 72wt% oxidized anode slime, 20wt% sodium chloride, and 8wt% sodium chlorate in a strong acid solution with a solid-to-liquid ratio of 1:3 and a concentration of 10mol / L, stir at 80°C for 4 hours, and filter to obtain acid Leach liquor and pickling residue.

[0063] 2) Hydrolysis of Tellurium Precipitation: Cooling and crystallizing the acid leaching solution and filtering to obtain the first filter residue and the first filtrate; recover antimony from the first filter residue; add an equal amount of water to the first filtrate to dilute, and adjust the pH value with alkaline solution 0 to obtain a hydrolyzed solution, the hydrolyzed solution is subjected to an insulated filtration step to obtain a second filter residue and a second filtrate; the second filt...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com