Extraction method of valuable elements from acid mud produced in sulfuric acid production by copper smelting flue gas

A technology of valuable elements and extraction methods, applied in the direction of element selenium/tellurium, improvement of process efficiency, etc., can solve the problem of low recovery rate of selenium, and achieve good and efficient separation effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

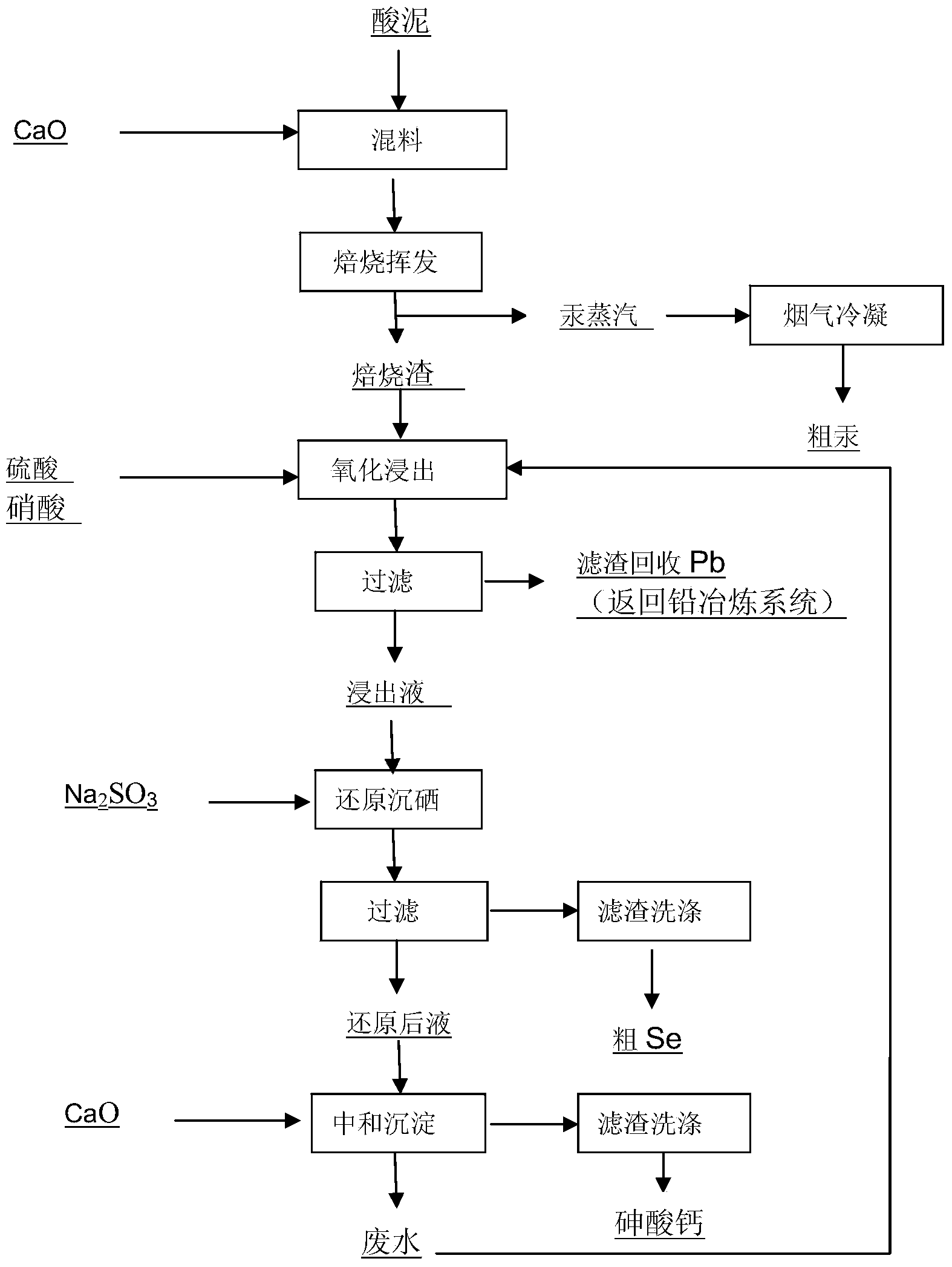

Method used

Image

Examples

Embodiment 1

[0050] Dry the acid mud and crush it to 120 mesh. The main components in the acid mud are calculated as (%) by mass percentage: Pb37.40, Se40.74, As3.14, Hg2.25. Take by weighing lime powder 28.4g, 50% lime powder is added in the selenium acid mud of 50g above-mentioned composition, mix homogeneously, place in the muffle furnace after remaining lime content is covered on the mixture surface, control roasting temperature is 450°C, roasting time 8h, after reaching the reaction time, weigh after cooling, the mercury-removed slag weighs 82.2g, and its main components are (%) by weight: Se24.8, As1.85, Hg0.14. The volatilization rates of Se, Hg, and As are 0, 99%, and 2.95%, respectively.

[0051] Use concentrated sulfuric acid with a mass fraction of 98% to prepare 120mL of a sulfuric acid solution with a concentration of 300g / L, add 20g of roasted slag under the condition of a stirring speed of 90r / min to obtain a mixed solution, and keep the temperature at 80°C for 4 hours in a ...

Embodiment 2

[0055] Dry the acid mud and crush it to 160 mesh. The main components in the acid mud are calculated as (%) by mass percentage: Pb37.40, Se40.74, As3.14, Hg. Take by weighing lime powder 61g, add 50% lime powder in the selenium acid mud of 50g above-mentioned composition, mix well, place in the muffle furnace after remaining lime content is covered on the mixed material surface, control roasting temperature is 700 ℃, roasting time 10h, after reaching the reaction time and weighing after cooling, the mercury removal slag weighs 112.59g, and its main components are calculated as mass percentages (%): Se18.09, As1.36, Hg<0.02; Se, Hg , As volatilization rates were 0, 99%, 2.46%.

[0056] Use concentrated sulfuric acid with a mass fraction of 98% to prepare 200mL of a sulfuric acid solution with a concentration of 324g / L, add 20g of mercury removal slag at a stirring speed of 100r / min to obtain a mixed solution, and keep the temperature at 80°C for reaction in a water bath 6h, du...

Embodiment example 3

[0060] Dry the acid mud and crush it to 200 meshes. The main components in the acid mud are (%): Pb37.40, Se40.74, As3.14, Hg. Take by weighing lime powder 35g, add 60% lime powder in the selenium acid mud of 50g above-mentioned composition, mix well, place in the muffle furnace after remaining lime content is covered on the mixed material surface, control roasting temperature is 850 ℃, roasting time 12h, after reaching the reaction time and weighing after cooling, the mercury-removed slag weighed 82.4g, and its main components were calculated as mass percentages (%): Se24.7, A1.86, Hg0.013; Se, Hg , As volatilization rates were 0, 99%, 2.44%.

[0061] Use concentrated sulfuric acid with a mass fraction of 98% to prepare 120mL of a sulfuric acid solution with a concentration of 400g / L, add 20g of mercury removal slag at a stirring speed of 120r / min to obtain a mixed solution, and keep the temperature at 85°C for reaction in a water bath 5h, during the leaching process, add ni...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com