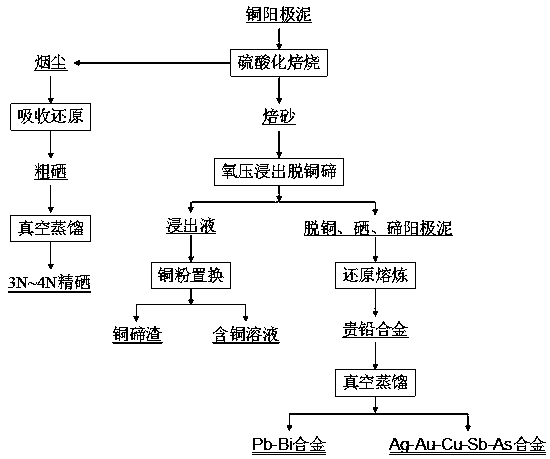

Method for recovering selenium, tellurium, copper and precious metal from copper anode slime

A technology for copper anode slime and selenium recovery, applied in the fields of tellurium, selenium recovery, copper and precious metals, can solve the problems of long process, high cost, large pollution, etc., and achieve the effects of simple process, low cost and environmental friendliness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] (1) Sulfate and roast copper anode slime in a rotary kiln to obtain SeO-containing 2 The soot and calcined sand, copper anode slime and sulfuric acid (98%) are slurried in the stirring tank at a mass ratio of 1:1, and the slurried anode slime is evenly sent to the rotary through the feeder in the feeding tank Kiln, for roasting operation, the roasting temperature is 500 °C, the time is 4h, the obtained SeO-containing 2 The soot is absorbed by water into H 2 SeO 3 solution, which is then absorbed by the SO in the soot 2 The gas is reduced to elemental selenium, and crude selenium is obtained after drying (the purity of selenium is 90% to 99%). The crude selenium is purified by vacuum distillation to obtain refined selenium (the heating method of the vacuum furnace is indirect heating, and the furnace temperature of the vacuum furnace is 400°C, vacuum degree 100Pa, distillation time 2h) to obtain refined selenium, the purity of refined selenium was tested according to ...

Embodiment 2

[0028] (1) Sulfate and roast copper anode slime in a rotary kiln to obtain SeO-containing 2 The soot and calcined sand, copper anode slime and sulfuric acid (98%) are slurried in the stirring tank at a mass ratio of 1:1, and the slurried anode slime is evenly sent to the rotary through the feeder in the feeding tank Kiln, for roasting operation, the roasting temperature is 520 ° C, the time is 3h, the obtained SeO-containing 2 The soot is absorbed by water into H 2 SeO 3 , which is then absorbed by the SO in the soot 2 The gas is reduced to elemental selenium, and crude selenium (90% to 99%) is obtained after drying, and the crude selenium is purified by vacuum distillation (the heating method of the vacuum furnace is indirect heating, the furnace temperature of the vacuum furnace is 310°C, and the vacuum degree is 30Pa , distillation time 1.5h) to obtain refined selenium, according to the industry standard YS / T223-2007 to detect the purity of refined selenium, the final pu...

Embodiment 3

[0034] (1) Sulfate and roast copper anode slime in a rotary kiln to obtain SeO-containing 2 The soot and calcined sand, copper anode slime and sulfuric acid (98%) are slurried in the stirring tank at a mass ratio of 1:1, and the slurried anode slime is evenly sent to the rotary through the feeder in the feeding tank Kiln, for roasting operation, the roasting temperature is 550 °C, the time is 2.5h, the obtained SeO-containing 2 The soot is absorbed by water into H 2 SeO 3 solution, which is then absorbed by the SO in the soot 2 The gas is reduced to elemental selenium, and crude selenium (90% to 99%) is obtained after drying. The crude selenium is purified by vacuum distillation to obtain refined selenium (the heating method of the vacuum furnace is indirect heating, and the furnace temperature of the vacuum furnace is 240 ° C. The concentration is 10Pa, the distillation time is 1h) to obtain refined selenium, and the purity of refined selenium is detected according to the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com