Method for preparing carbon nanofiber membrane

A carbon nanofiber and tellurium nanotechnology applied in the field of nanomaterials to achieve good flexibility, uniform diameter, and controllable pore size

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0031] The invention provides a kind of preparation method of carbon nanofiber membrane, comprises the following steps:

[0032] a) mixing tellurium nanowires and glucose in an aqueous solution, and performing a carbonization reaction to obtain carbon-coated tellurium nanocables;

[0033] b) adding hydrochloric acid and hydrogen peroxide to the carbon-coated tellurium nano-cable, and performing an oxidation reaction to obtain carbon nanofibers;

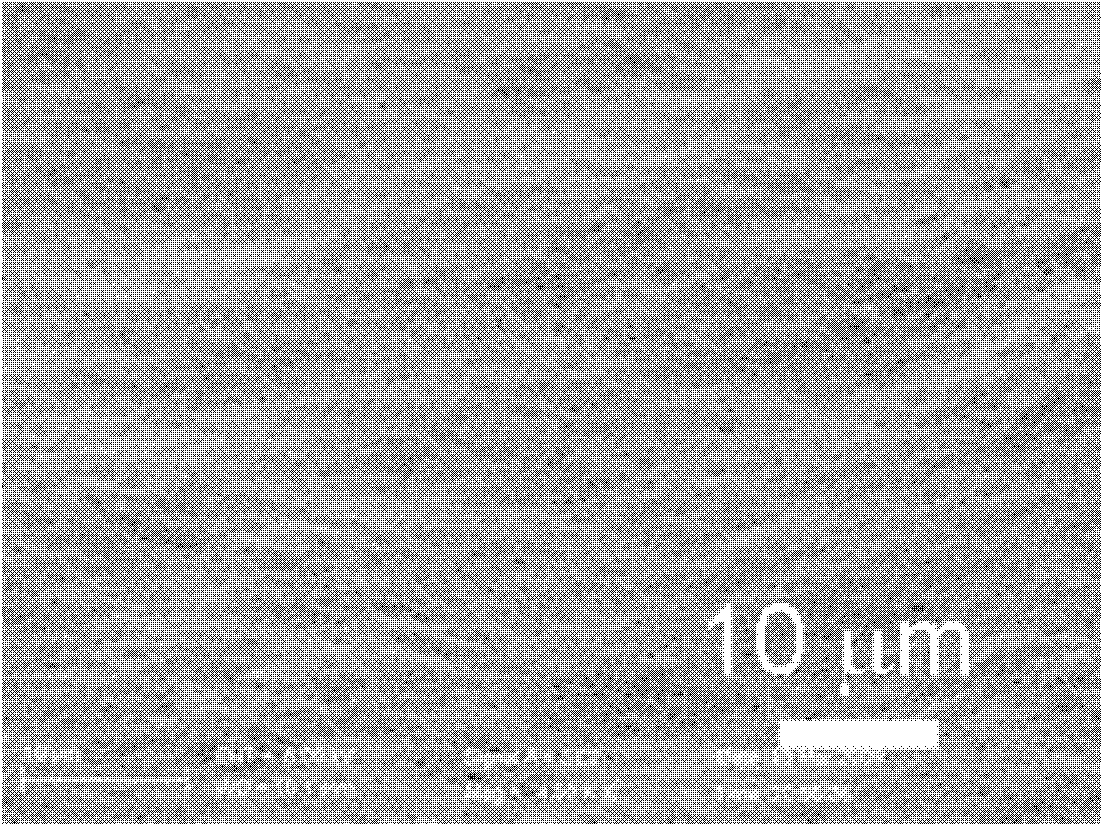

[0034] c) dispersing the carbon nanofibers in a solvent to obtain a slurry, applying the slurry on a support material, and drying to obtain a carbon nanofiber film.

[0035] The present invention uses tellurium nanowires as a template and glucose as a raw material to obtain carbon-coated tellurium nano-cables; then hydrogen peroxide is used as an oxidant to remove the tellurium core in carbon-coated tellurium nano-cables in the presence of hydrochloric acid to obtain carbon nano-cables. fibers; and then carbon nanofibers are formed i...

Embodiment 1

[0051] 1g polyvinylpyrrolidone and 92mg Na 2 TeO 3 Add it into 32mL of water, stir evenly, then add 1.67mL of hydrazine hydrate and 3.33mL of ammonia water, stir until the phases are evenly separated, then place in a sealed container, raise the temperature to 180°C and react for 3 hours to obtain Te nanowires, adjust the concentration of Te nanowires , to obtain 0.18g / L Te nanowire aqueous solution;

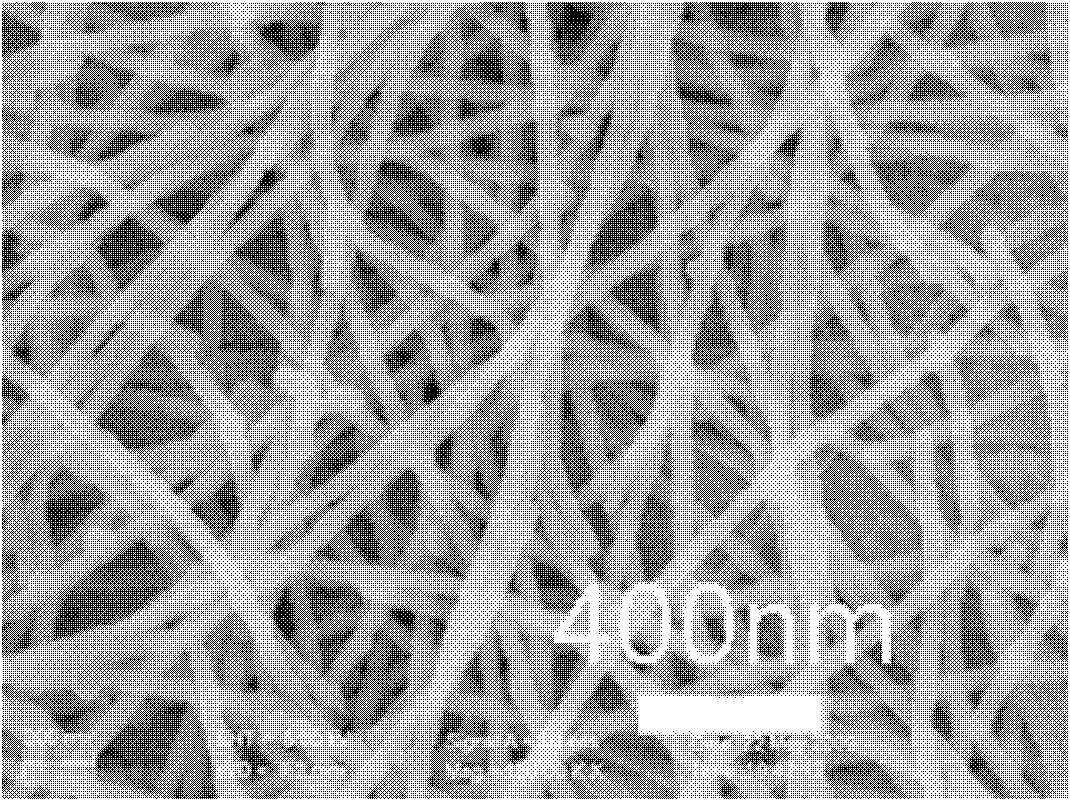

[0052] Mix 100mL of the Te nanowire aqueous solution with 100mL of 67g / L glucose aqueous solution, stir evenly, place in an airtight container, and carry out hydrothermal carbonization reaction at 160°C. After reacting for 18h, cool to room temperature to obtain C-coated Te nanowires. Cable, adjust the concentration of the Te nano-cable covered by the C, obtain the Te nano-cable aqueous solution of 5g / L;

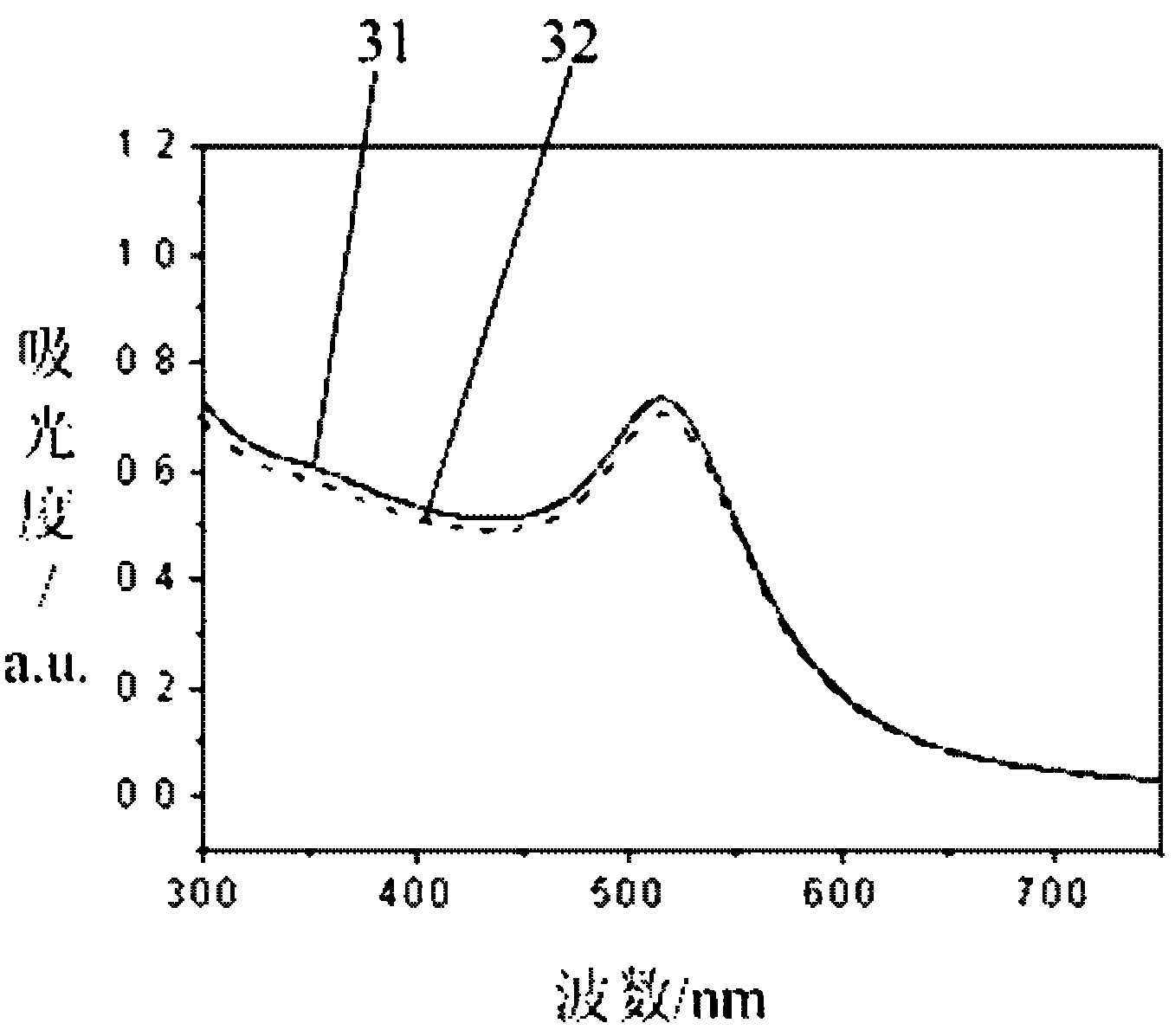

[0053] Add 100 mL of 0.5 mol / L hydrochloric acid and 100 mL of 0.5 mol / L hydrogen peroxide to 100 mL of Te nanocable aqueous solution, stir and react, centrifuge, wash and dr...

Embodiment 2

[0063] 1g polyvinylpyrrolidone and 92mg Na 2 TeO 3 Add it into 32mL of water, stir evenly, then add 1.67mL of hydrazine hydrate and 3.33mL of ammonia water, stir until the phases are evenly separated, then place in a sealed container, raise the temperature to 180°C and react for 3 hours to obtain Te nanowires, adjust the concentration of Te nanowires , to obtain 0.18g / L Te nanowire aqueous solution;

[0064] Mix 100mL of the Te nanowire aqueous solution with 100mL of 67g / L glucose aqueous solution, stir evenly, place in a closed container, and carry out hydrothermal carbonization reaction at 160°C. After reacting for 24h, cool to room temperature to obtain C-coated Te nanowires. Cable, adjust the Te nano-cable of described C coating, obtain the Te nano-cable aqueous solution of 5g / L;

[0065] Add 100 mL of 0.5 mol / L hydrochloric acid and 100 mL of 0.5 mol / L hydrogen peroxide to 100 mL of Te nanocable aqueous solution, stir and react, centrifuge, wash and dry the reaction mix...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com