Preparation method for nano-selenium

A technology of nano-selenium and selenite, which is applied in nanotechnology, nanotechnology, nanotechnology for materials and surface science, etc., can solve the problem of inability to produce nano-selenium particles, and achieve uniform particle size and application. promising effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] 1) Prepare 20mM sodium selenite solution, 80mM sodium lauryl sulfate stabilizer solution, 80mM hydrochloric acid solution and 300mM sodium thiosulfate pentahydrate reducing agent solution respectively.

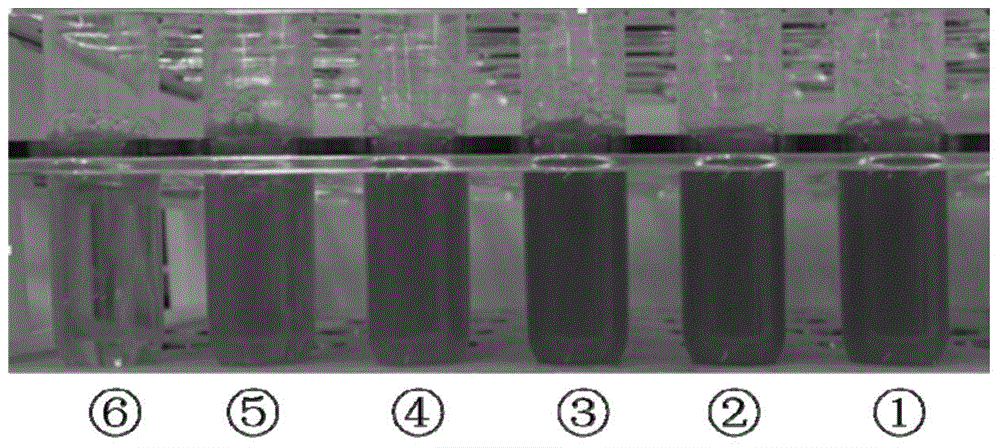

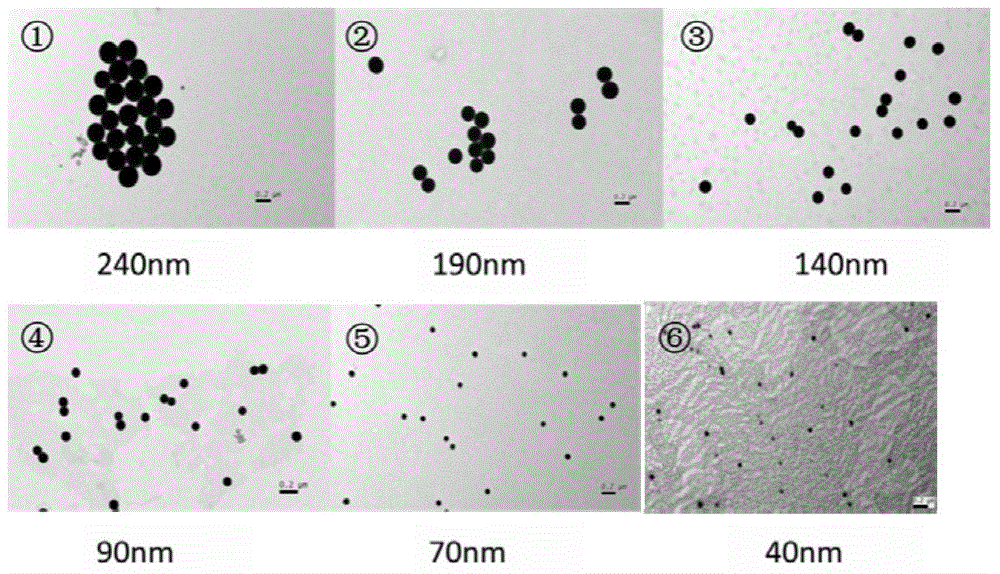

[0032] 2) Add selenite solution, acid solution, stabilizer solution, water and reducing agent solution successively in reaction system under normal temperature and pressure, make selenite solution, acid solution, stabilizer solution and reducing agent solution press The mass ratio of solute is 1:2:2:2. The mixture was fully mixed evenly, and left to react at room temperature for 8 hours to obtain a red nano-selenium suspension. Centrifuge the nano-selenium suspension at 10,000 rpm for 20 minutes, remove the supernatant, and obtain the finished colloidal nano-selenium. The nano-selenium suspension is observed under a transmission electron microscope, and the average particle size of the nano-selenium is measured and calculated, and the particle size is about 240nm.

[...

Embodiment 2

[0039] Compared with embodiment 1, the difference is only in:

[0040] The selenite is potassium selenite, the concentration is 18mM; the reducing agent is sodium thiosulfate pentahydrate, the concentration is 280mM; the stabilizer is sodium lauryl sulfate, the concentration is 70mM; the acid solution is hydrochloric acid, the concentration is 70mM ;

[0041] The selenite solution, acid solution, stabilizer solution and reducing agent solution are mixed thoroughly and evenly according to the solute mass ratio of 1:2:2:3, and left to stand for 8 hours at room temperature to obtain a red color with an average particle size of about 190nm. nanoselenium suspension. The above nano-selenium suspension was centrifuged at 10000 rpm for 20 minutes, and the supernatant was removed to obtain the finished colloidal nano-selenium.

[0042] The photo of the nano-selenium suspension that this embodiment obtains is attached figure 1 test tube 2. The transmission electron microscope (TEM) ...

Embodiment 3

[0045] Compared with embodiment 1, the difference is only in:

[0046] The selenite is zinc selenite, the concentration is 25mM; the reducing agent is sodium thiosulfate pentahydrate, the concentration is 350mM; the stabilizer is sodium lauryl sulfate, the concentration is 90mM; the acid solution is hydrochloric acid, the concentration is 90mM ;

[0047] The selenite solution, acid solution, stabilizer solution and reducing agent solution are mixed thoroughly and uniformly according to the solute mass ratio of 1:2:2:4, and left to stand for reaction at room temperature for 6 hours, and the average particle diameter of about 140nm can be obtained respectively. Red nanoselenium suspension. The above nano-selenium suspension was centrifuged at 11000 rpm for 30 minutes, and the supernatant was removed to obtain the finished colloidal nano-selenium.

[0048] The photo of the nano-selenium suspension that this embodiment obtains is attached figure 1 Test tube 3. The transmission...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com