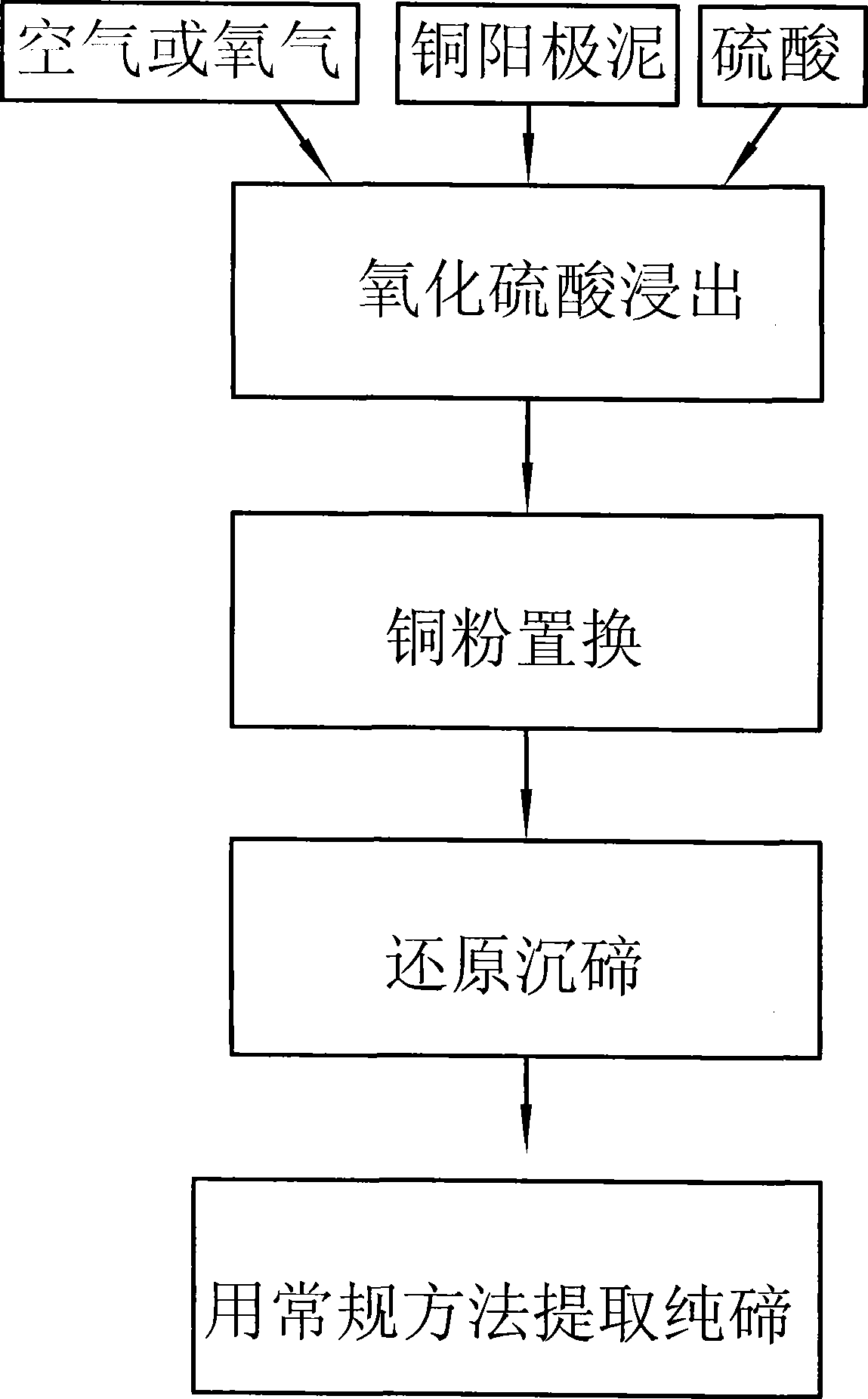

Process for extracting tellurium from copper anode mud

A copper anode slime and process technology, applied in the field of tellurium extraction from copper anode slime, can solve the problems of difficult wastewater treatment, unfavorable operation management, complex process, etc. Good, the effect of simplifying the process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0028] Add copper anode slime to 100g / L sulfuric acid solution, oxidize leaching with oxygen, liquid-solid weight ratio 2:1, leaching temperature 100°C, leaching for 4 hours, replace the obtained copper-tellurium leaching solution with copper powder, and pass it into sulfur dioxide for reduction. The reduction temperature is 25°C, the reduction time is 1 h, and the total recovery rate of tellurium is 87.8%.

Embodiment 2

[0030] Add copper anode slime to 400g / L sulfuric acid solution, oxidize leaching with oxygen, liquid-solid weight ratio is 5:1, leaching temperature is 80°C, leaching for 4 hours, the obtained copper tellurium leaching solution is replaced with copper powder, then passed through sulfur dioxide for reduction, The reduction temperature is 45°C, the reduction time is 0.5h, and the total recovery rate of tellurium is 88.5%.

Embodiment 3

[0032] Add copper anode slime to 200g / L sulfuric acid solution, oxidize and leaching with oxygen, liquid-solid weight ratio 1:1, leaching temperature 120°C, leaching for 8 hours, replace the obtained copper tellurium leaching solution with copper powder, and pass through sulfur dioxide for reduction. The reduction temperature is 60°C, the reduction time is 3 hours, and the total recovery rate of tellurium is 91.8%.

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com