Silicane coupling agent surface grafted modified clay as well as preparation method and use thereof

A silane coupling agent and surface grafting technology, applied in chemical instruments and methods, silicon compounds, inorganic chemistry, etc., can solve problems such as unstable nanocomposite materials, limited types of terminal functional groups, and poor thermal stability of organoclays , to achieve high thermal stability, improve interfacial interaction, and improve the effect of dispersing ability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

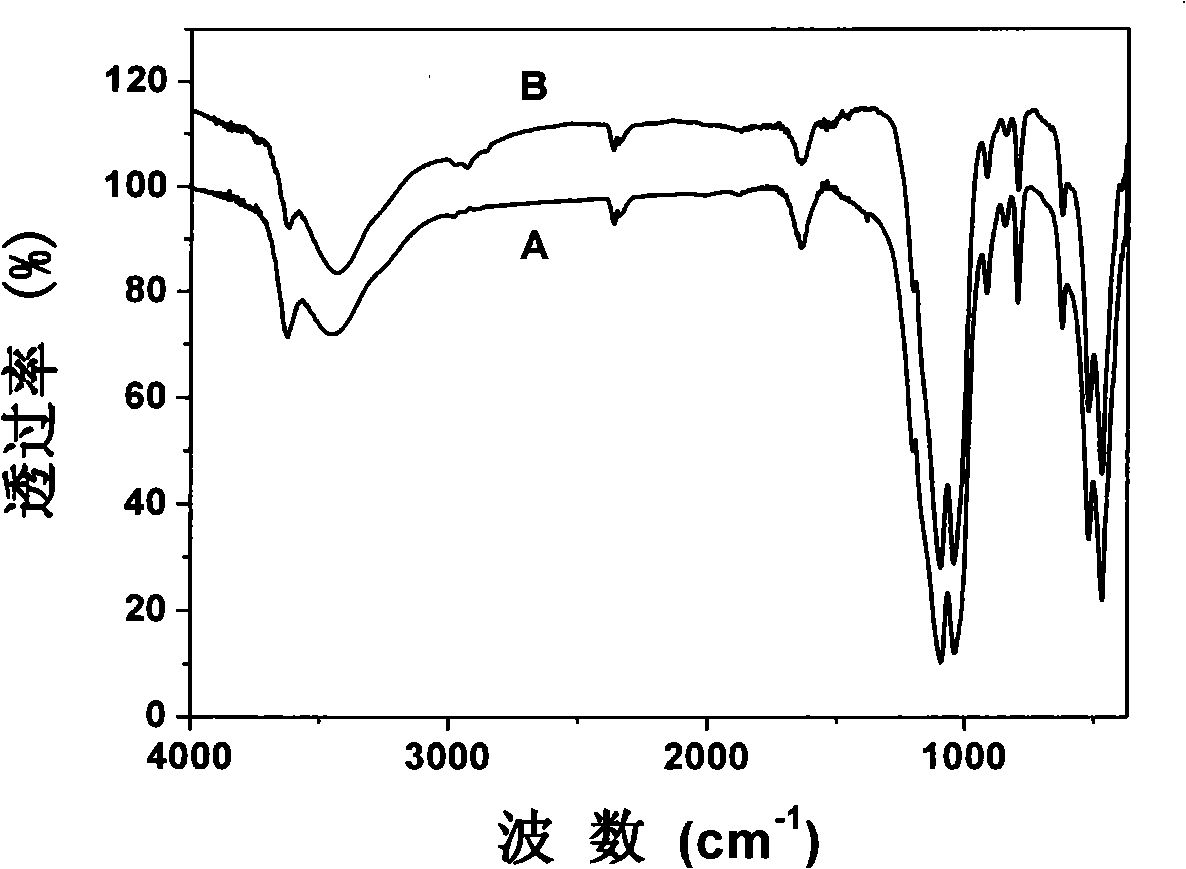

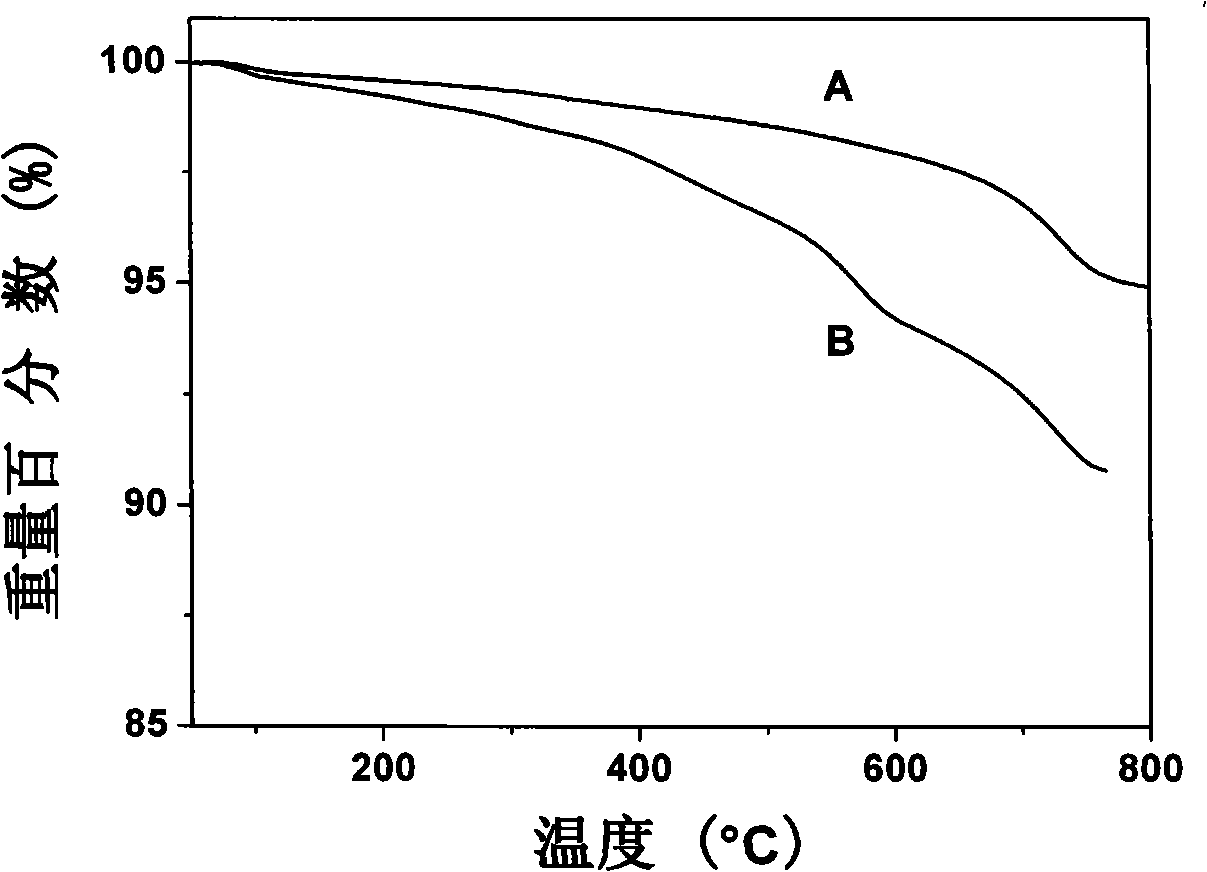

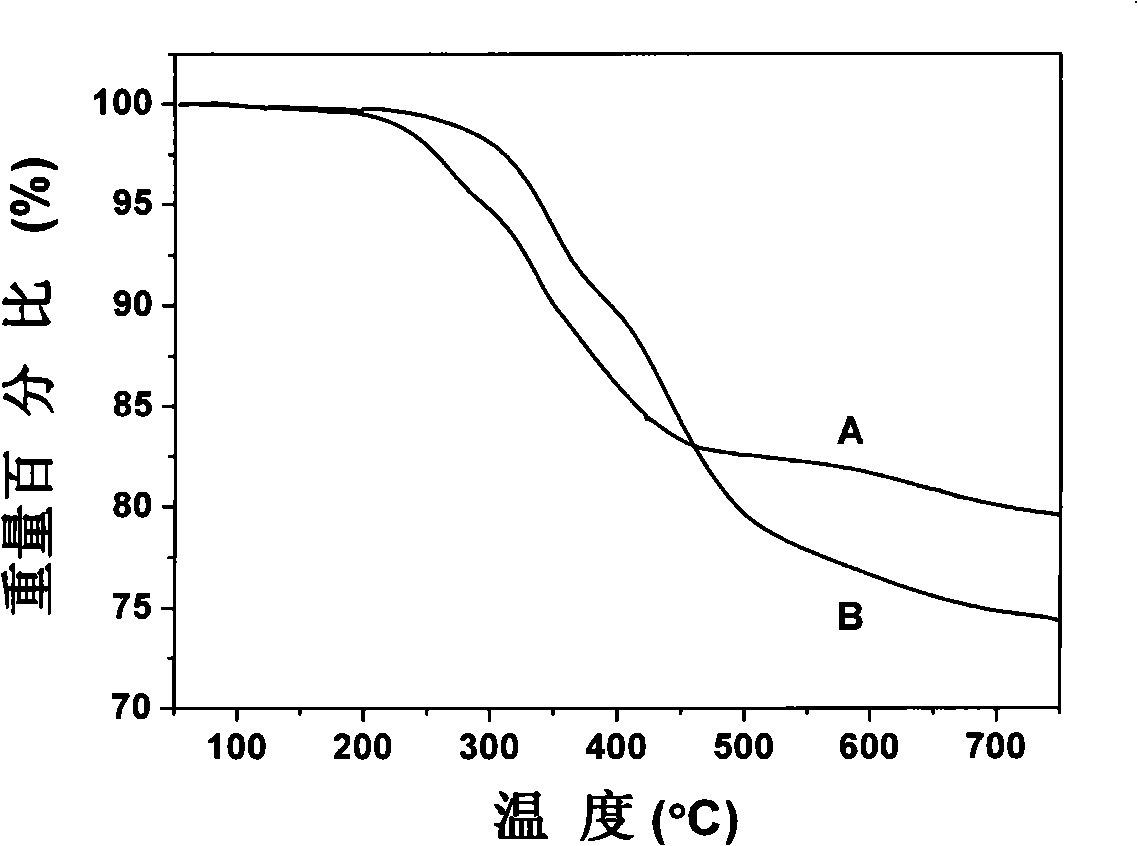

[0038] Disperse 10g of untreated montmorillonite inorganic clay in 200mL of toluene, stir until uniformly dispersed, and form a stable suspension. Slowly drop 5 mL of dodecyltrimethoxysilane into the suspension, stir mechanically, raise the temperature to 110° C., and reflux for 24 hours. After the reaction, the Buchner funnel was suction-filtered, and the filter cake was washed several times with toluene, dried at 80°C for 24 hours, and ground into powder to obtain a modified clay grafted with dodecyltrimethoxysilane on the surface. The grafting amount of dodecyltrimethoxysilane on the modified clay surface grafted with dodecyltrimethoxysilane was measured by TGA to be 0.26×10 -3 mol / g clay.

Embodiment 2

[0040] Measure 80 mL of absolute ethanol and 20 mL of deionized water, mix them in a beaker, and stir them magnetically; add glacial acetic acid to adjust the pH between 4 and 5, add 10 mL of dodecyltrimethoxysilane, and continue stirring at room temperature for 1 hour. A silane solution was obtained.

[0041] Disperse 10g of untreated montmorillonite inorganic clay in a mixed solvent composed of 90mL of n-butanol and 10mL of deionized water, stir until it is uniformly dispersed to form a stable suspension, and add the silane solution obtained by the above method dropwise into the clay suspension In the middle, heat up to 78°C, add glacial acetic acid, adjust the pH between 4 and 5, stir mechanically, and react for 24 hours. After the reaction was completed, the Buchner funnel was suction-filtered, and the filter cake was washed several times with a mixed solvent of absolute ethanol / deionized water until the pH value of the filtrate was 6-7. Dry at 80°C for 24 hours, grind int...

Embodiment 3

[0043] Measure 180mL of absolute ethanol and 20mL of deionized water, mix them in a beaker, and stir mechanically; add glacial acetic acid to adjust the pH between 4 and 5, add 5mL of dodecyltrimethoxysilane, and continue stirring at room temperature for 1 hour. A silane solution was obtained.

[0044] Disperse 10g of untreated montmorillonite inorganic clay in a mixed solvent composed of 180mL of absolute ethanol and 20mL of deionized water, stir until it is uniformly dispersed to form a stable suspension, add the silane solution obtained by the above method dropwise into the clay to suspend In the liquid, heat up to 78°C, add sodium hydroxide solution, adjust the pH between 9 and 10, stir mechanically, and react for 24 hours. After the reaction was completed, the Buchner funnel was suction-filtered, and the filter cake was washed several times with a mixed solvent of absolute ethanol / deionized water until the pH value of the filtrate was 6-7. Dry at 80°C for 24 hours, grind ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Grafting amount | aaaaa | aaaaa |

| Grafting amount | aaaaa | aaaaa |

| Grafting amount | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com