Method of preparing cationic polyacrylamide paper making intensifier

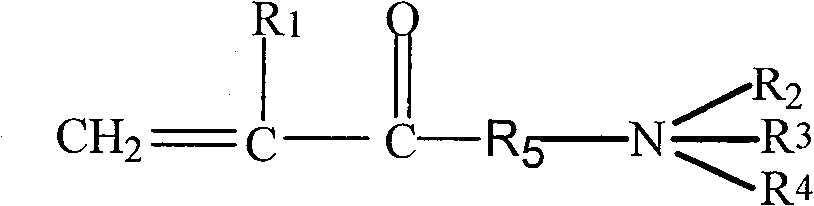

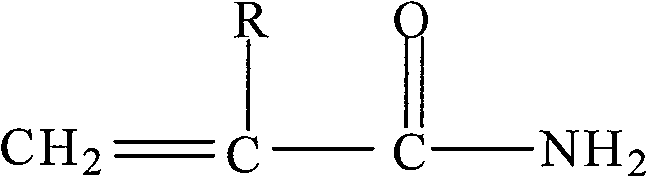

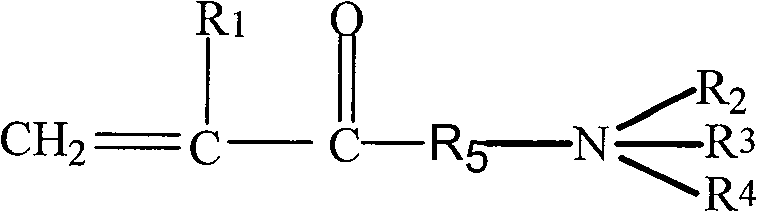

A technology of polyacrylamide and paper-making strengthening agent, which is applied in the direction of strengthening agent addition, which can solve the problems of poor water solubility, pollution, production cost, and poor fluidity of the product, and achieve good solubility, improved uniformity, and reduced system viscosity.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0015] Example 1, first, the acrylamide monomer was mixed with polyethylene oxide with a relative molecular mass of 20,000 in a mass ratio of 1:0.5, then water was added to make the content of the acrylamide monomer 18%, and then the mass of the acrylamide monomer was added. 15% of the cationic monomer dimethylamine ethyl methacrylate and 8% of potassium persulfate can be polymerized at 80° C. for 4 hours.

[0016] The conversion rate of the product was measured by the potassium bromate potassium bromide method, and the conversion rate exceeded 98%. The viscosity was measured by a rotor viscometer, and the viscosity was 5Pa·s, which was far less than the general aqueous solution polymerization.

[0017] At the same time, the solubility of the product was tested, adding 2 g of the polymer emulsion to 100 g of water, stirring gently, and quickly dissolving into a transparent solution. However, with the same amount of cationic acrylamide, it takes more than 1 hour to dissolve com...

Embodiment 2

[0018] Example 2: First, mix acrylamide monomer and polyethylene oxide with a relative molecular mass of 50,000 in a mass ratio of 1:1.2, then add water to make the content of acrylamide monomer 23%, and then add the mass of acrylamide monomer 20% of the cationic monomer dimethyl diallyl ammonium chloride and 5% of sodium persulfate can be polymerized at 80°C for 6 hours.

[0019] The conversion rate of the product was measured by the potassium bromate potassium bromide method, and the conversion rate exceeded 97%. The viscosity was measured by a rotor viscometer, and the viscosity was 5.8Pa·s.

[0020] At the same time, the solubility of the product was tested, adding 2 g of the polymer emulsion to 100 g of water, stirring gently, and quickly dissolving into a transparent solution.

Embodiment 3

[0021] Example 3: First, mix acrylamide monomer and polyethylene oxide with a relative molecular mass of 10,000 in a mass ratio of 1:1.7, then add water to make the content of acrylamide monomer 10%, and then add the mass of acrylamide monomer. 30% of the cationic monomer acryloylethyltrimethylbenzyl ammonium chloride and 3% of ammonium persulfate can be polymerized at 70° C. for 7.5 hours.

[0022] The conversion rate of the product was measured by the potassium bromate potassium bromide method, and the conversion rate exceeded 98%. The viscosity was measured by a rotor viscometer, and the viscosity was 7Pa·s.

[0023] At the same time, the solubility of the product was tested, adding 2 g of the polymer emulsion to 100 g of water, stirring gently, and quickly dissolving into a transparent solution.

PUM

| Property | Measurement | Unit |

|---|---|---|

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

| viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com