Cannabinoid Containing Cannabis Extract Infused into Rolling Paper

a cannabinoid and cannabis extract technology, applied in the field of rolling paper manufacturing, can solve the problems of lack of consistency of concentration, lack of large-scale manufacturers of cigarettes made from tobacco or i>cannabis/i>leaves, oily composition of cannabinoids, etc., and achieves the effect of convenient and substantially uniform dispersion and easy application

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0048]According to the preferred embodiment, cannabinoids are infused into paper during the paper-making / creation process. It is well known that the paper-making process uses a significant amount of water in the various steps of the process. According to well-known paper-making processes, there are three or four principal steps, pulping, filling or web forming, and sizing (and then drying). A binding agent is often used in the creation of paper. To form conventional rolling papers, a binding agent is used in one step, a filling agent used in another step and a sizing agent also used.

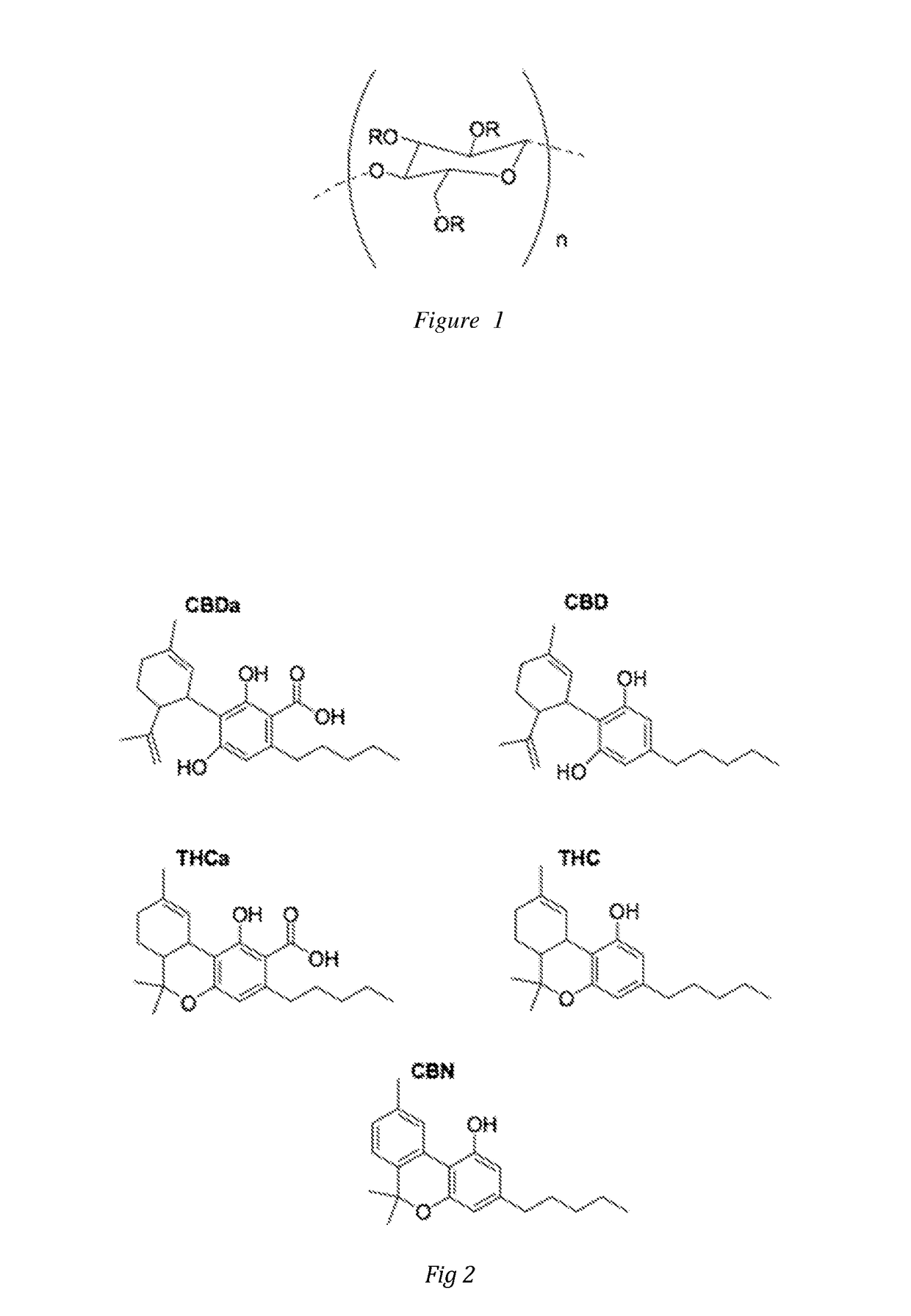

[0049]According to the preferred embodiment of the present invention, the infusion of the cannabinoids, in the form of a liquid, is desirably done during the sizing step but can also or alternatively be performed during the pulping, binding step and / or the filling step of paper-making. FIG. 1 shows a representative chemical formula for the single starch unit useful in connection with the present inventio...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Volume | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com