Aqueous pigment preparations

A technology for water-based pigments and pigment preparations, which is used in the field of coloring natural and synthetic materials, and can solve problems such as difficulty in synthesizing dispersants

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

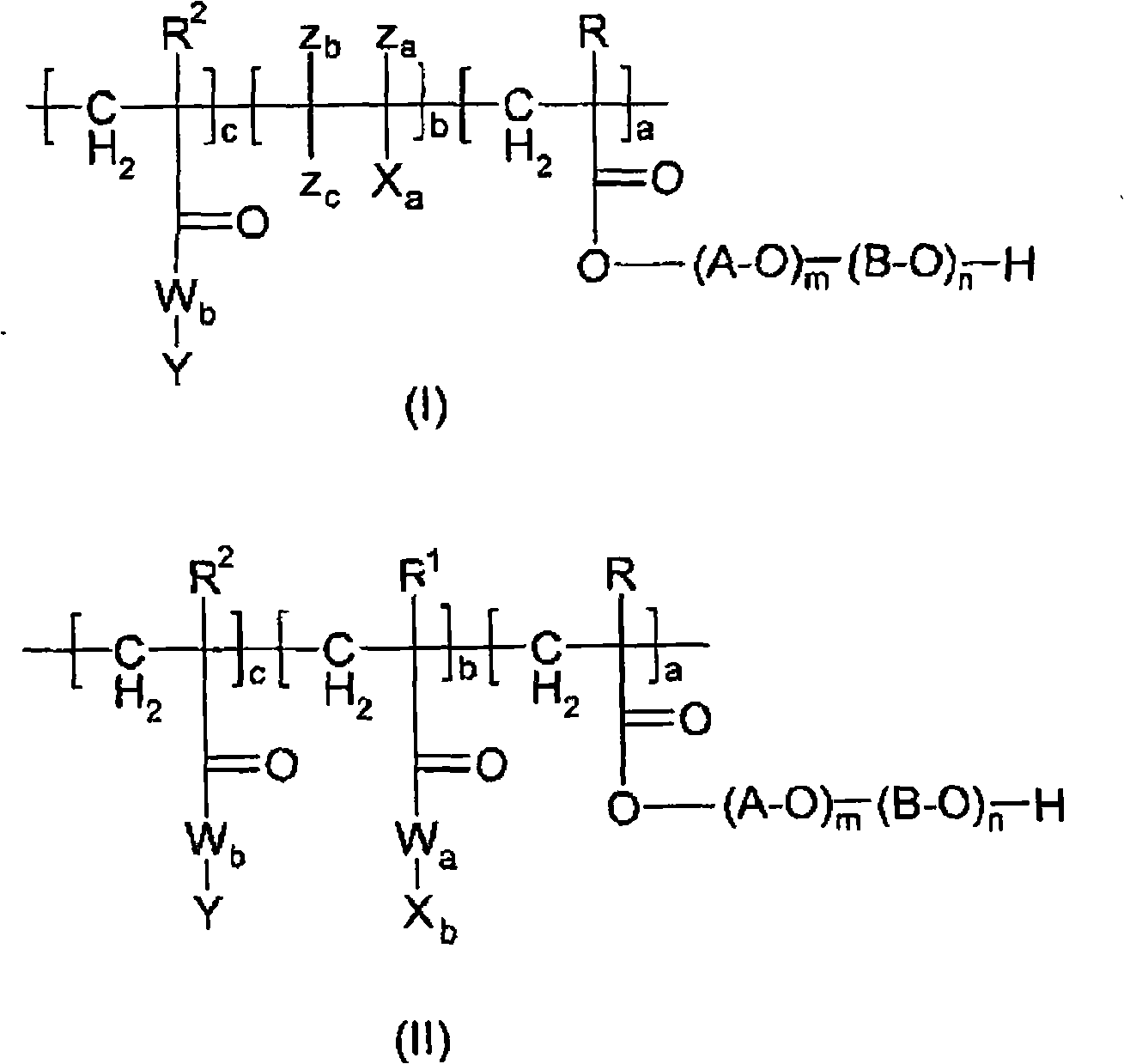

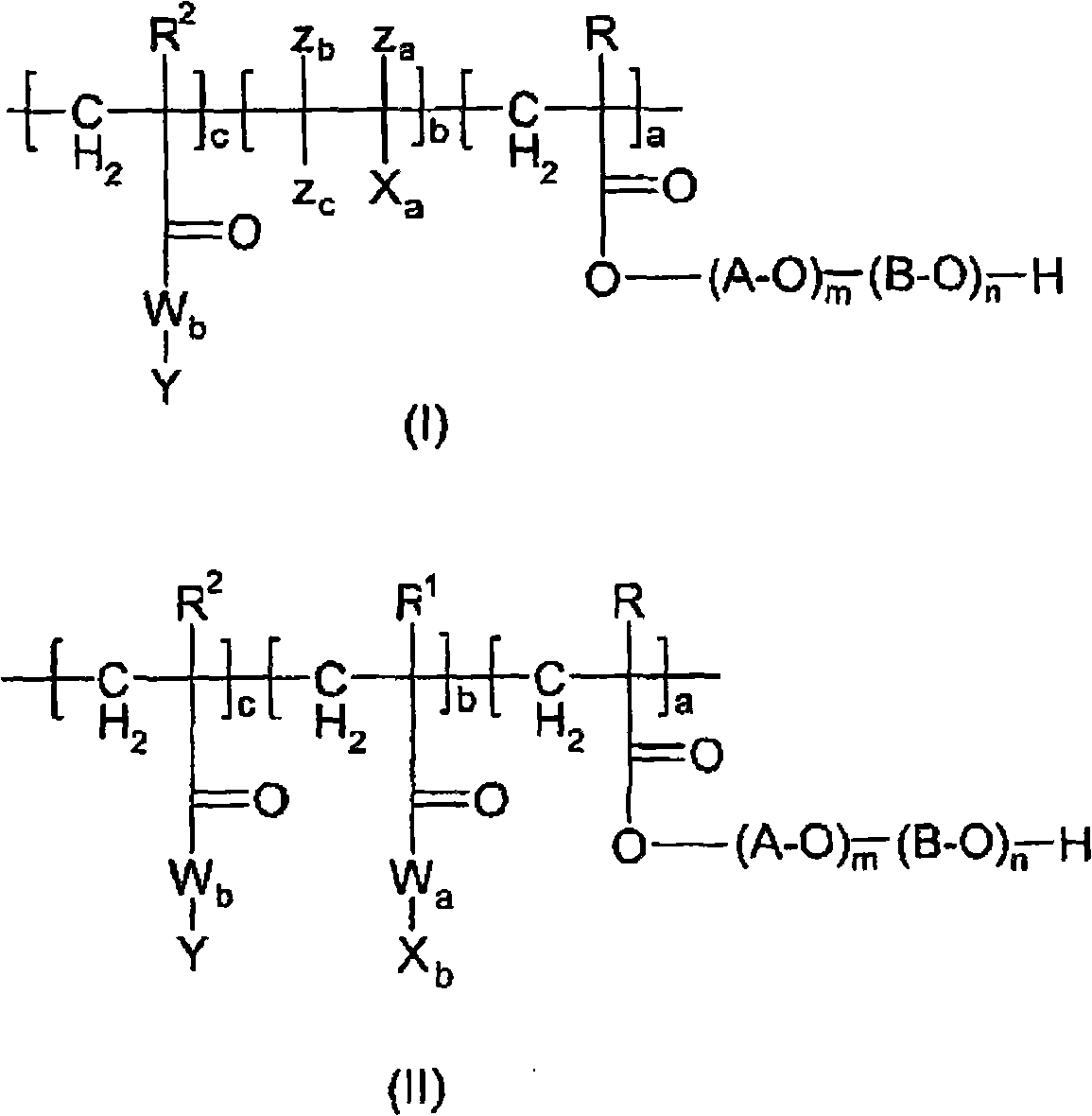

Method used

Image

Examples

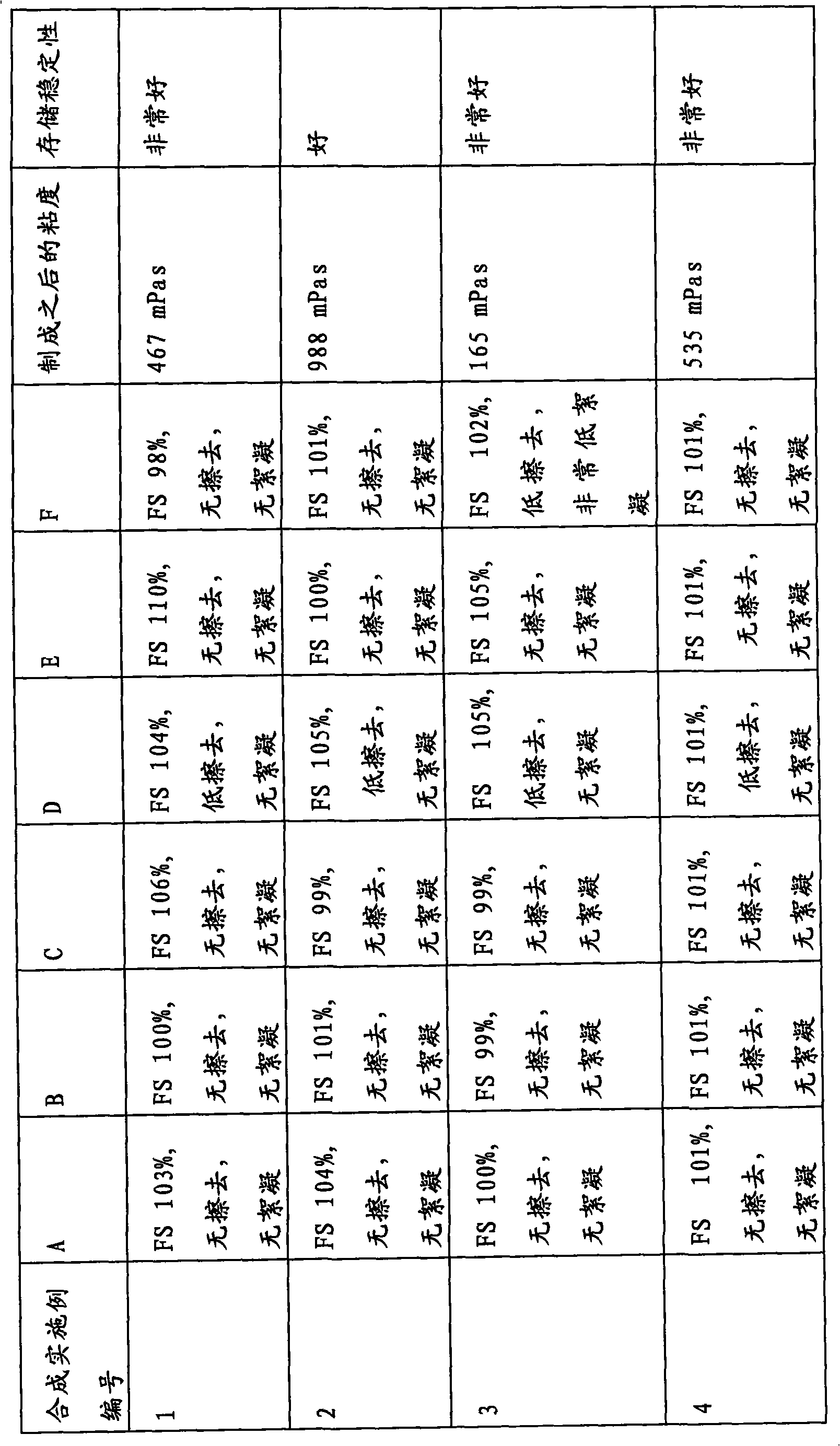

Embodiment 1

[0084] Using the following starting materials, the following Synthesis Examples were carried out analogously to Synthesis Example 1:

[0085] Synthesis Example 2

[0086] 210g polyalkylene glycol monomethacrylate (molar mass 350, EO / PO molar ratio 1.7), 79.2g 2-ethylhexyl methacrylate, 41.6g styrene.

[0087] Synthesis Example 3

[0088] 258g polyalkylene glycol monomethacrylate (molar mass 750, EO / PO molar ratio 6.3), 87.5g lauryl methacrylate, 35.8g styrene.

[0089] Synthesis Example 4

[0090] 210g polyalkylene glycol monomethacrylate (molar mass 350, EO / PO molar ratio 1.7), 101.6g lauryl methacrylate, 41.6g styrene.

[0091] Synthesis Example 5

[0092] 363 g polyalkylene glycol monomethacrylate (molar mass 1100, EO / PO molar ratio 10.2, 70% strength in tert-butanol), 117.3 g lauryl methacrylate, 48.0 g styrene.

[0093] Synthesis Example 6

[0094] 452 g polyalkylene glycol monomethacrylate (molar mass 2000, EO / PO molar ratio 20.5, 70% strength in tert-butanol), 80....

Embodiment 2

[0155] 45.0 parts Component (A), C.I. Pigment Red 112

[0156] 8.0 parts of component (B), corresponding to the dispersant of synthetic example 23

[0157] 1.0 parts component (C), moisturizing agent

[0158] 10.0 parts component (E), propylene glycol

[0159] 0.2 part of component (F), preservative

[0160] The remainder of component (G), water

[0161] The pigment preparations have consistently high tinting strength and are stable. It can be incorporated very well into all six white dispersions with easy dispersibility. The rub off test showed no difference in tinting strength in these six cases compared to the back rubbed surface. This formulation proved to flow well and to be storage stable, since it also flowed well after storage at 50° C. for 28 days. The viscosity after production was 278 mPa·s. The formulation is shear stable and does not foam.

Embodiment 3

[0163] 65.0 parts of component (A), C.I. Pigment Yellow 42

[0164] 4.0 parts of component (B), corresponding to the dispersant of synthetic example 11

[0165] 1.0 parts component (C), moisturizing agent

[0166] 15.0 parts component (E), propylene glycol

[0167] 0.2 part of component (F), preservative

[0168] The remainder of component (G), water

[0169] The pigment preparations have consistently high tinting strength and are stable. It can be incorporated very well into the five white dispersions with easy dispersibility; incorporation becomes difficult in the sixth white dispersion, but can be done uniformly. The rub off test showed no difference in tinting strength in these six cases compared to the back rubbed surface. This formulation proved to flow well and to be storage stable, since it also flowed well after storage at 50° C. for 28 days. The viscosity after production was 1765 mPa·s. The formulation is shear stable and does not foam.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com