Tissue product with silk fibers and method of making the same

a technology of tissue products and silk fibers, applied in the field of tissue products and the making of tissue products, can solve the problems of irritating, redness or damage to the skin, limited use of silk fibers in industrial paper making processes, and fibers are relatively expensive raw materials (several times more expensive)

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

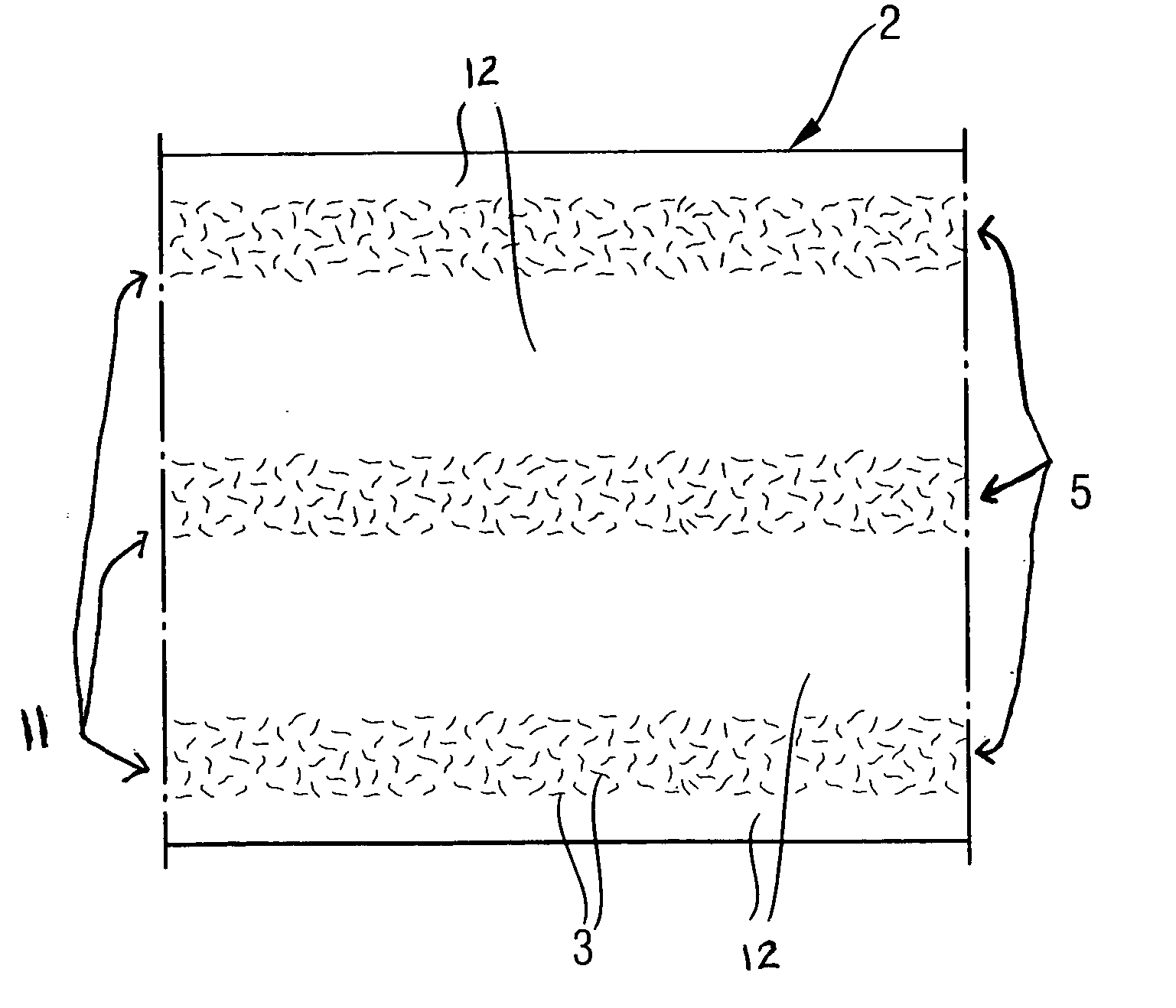

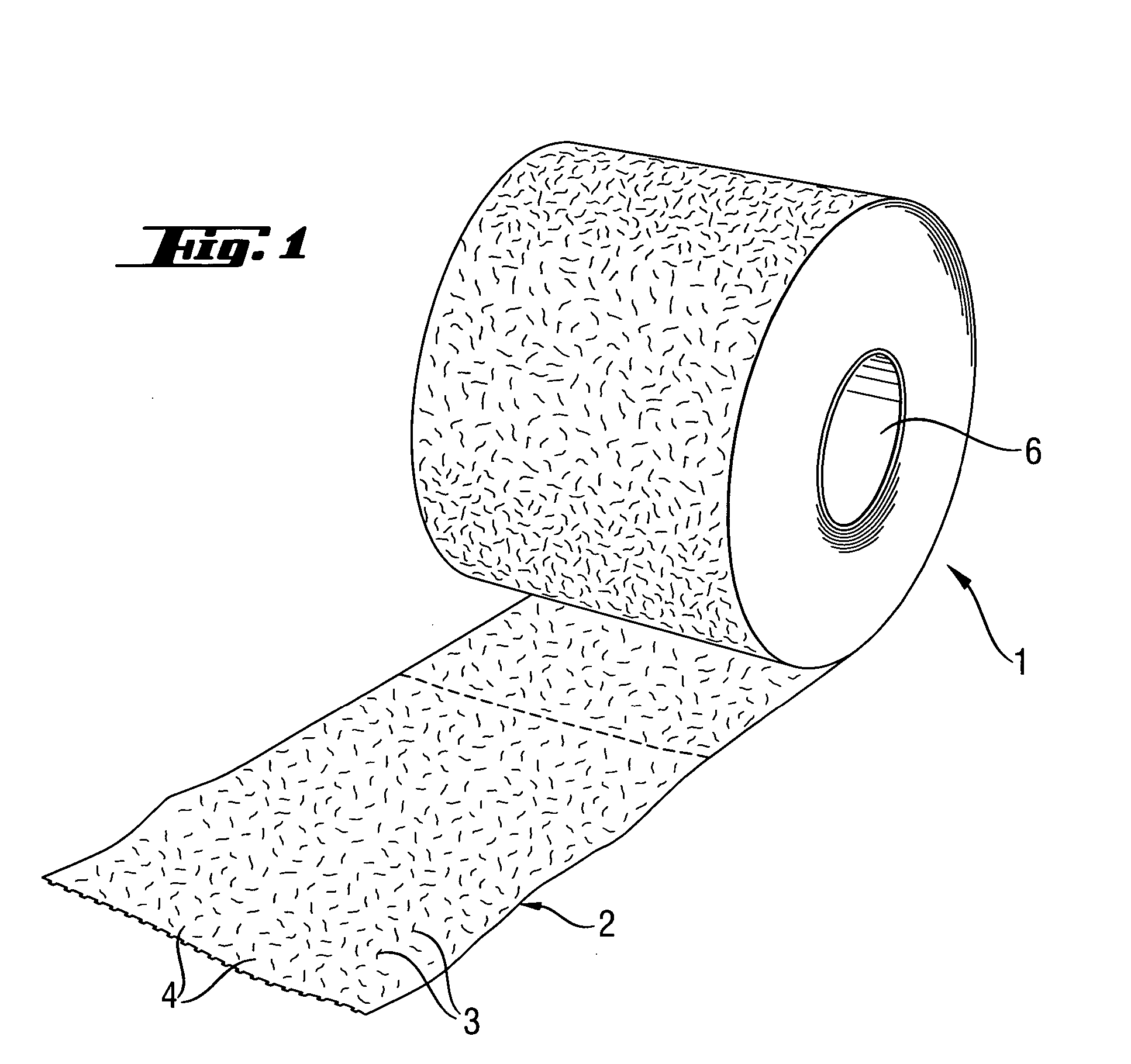

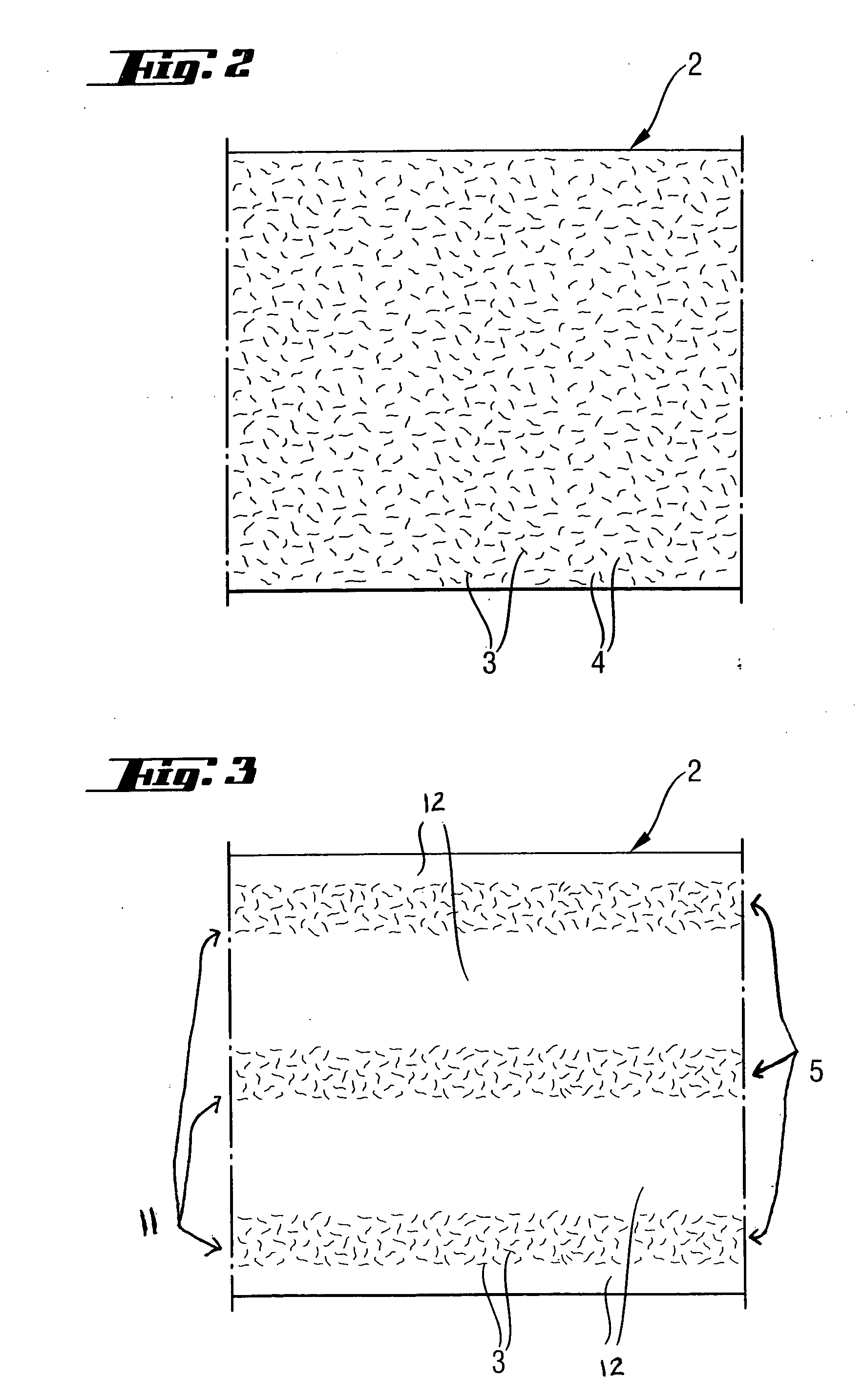

[0052] Silk fibers (Tussah silk cut from SEAL International Limited, Ladywell Mills, Hall Lane, Bradford, West Yorkshire, BD4 7DF, England; Silk cut) are first colored with a blue colorant (“Marabu-SilkArt azure” from Marabuwerke GmbH & Co. KG, Asperger StraBe 4, 71732 Tamm, Germany). The silk fibers are then added at a level of 0.1% (w / w) of the total amount of fibers used, into the mixing vessel for the preparation of the papermaking slurry. The hybrid slurry (cellulose fibers+silk fibers) is then used in a usual papermaking process (for example as described in U.S. Pat. No. 3,301,746 by Sanford et al, EP0536320B1 by Trokhan et al, and U.S. Pat. No. 4,529,480 by Trokhan et al.). The web of tissue paper is then converted into a roll of toilet paper by conventional industrial processes. Pieces of issue papers are then evaluated for the visibility of the silk fibers on the tissue paper and for physical properties.

example 2

[0053] The same silk fibers as described in Example 1 are used at a level of 0.01%, 0.05%, 0.1%, 0.5%, 1%, 2% and 5% (w / w) of the total amount of fibers, to form fiber mixes. The fiber mixes comprises cellulosic fibers and silk fibers. In additional assays, synthetic fibers (polypropylene) are also added to the fiber mixes, at a level of 1%, 5%, 10%, and 20% (w / w) of the total amount of fibers. The cellulosic fibers are usual cellulosic fibers commonly used for paper-making. The fiber mixes are used as a base to form hand-sheets of tissue paper as described in TAPPI method T-205 (TAPPI, Technical Association of the Pulp and Paper Industry, published method T 205 sp-95, approved by the Pulp Committee of the Process Quality Division TAPPI, ISBN 0-89852-334-6). The sheets of tissue paper are then evaluated for the visibility of the silk fibers on the tissue paper and for physical properties.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

| Fraction | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com