Automobile engine thermostat and thermoregulation method thereof

A technology for automobile engines and thermostats, which is applied to the cooling of engine components, machines/engines, and engines. It can solve problems such as difficult reliability assurance, limited valve thickness, and high production costs, and meet processing technical requirements and costs. The effect of low, precise control and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

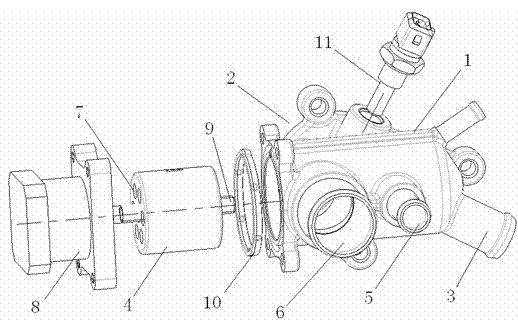

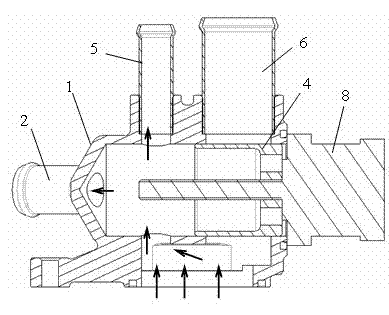

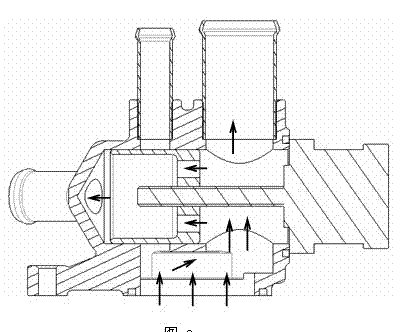

[0018] like figure 1 As shown, the automobile engine thermostat of this embodiment includes a housing 1, the bottom of the housing 1 is provided with a water inlet 2, one end of the housing 1 is provided with an auxiliary water outlet 3, and the other end opposite to the auxiliary water outlet 3 is provided There is a cylindrical piston valve 4 that can move in the housing, and the top of the housing 1 is provided with a small circulation water outlet 5 and a large circulation water outlet 6 along the movement direction of the piston valve 4; the valve body of the piston valve 4 is provided with an axial The through hole 7 of the piston valve 4 and the motor 8 arranged at the end of the housing 1, the motor shaft 9 of the motor 8 is provided with threads, and the valve body of the piston valve 4 is provided with a screw hole matched with the motor shaft 9; the motor 8 passes through Bolts are connected to the casing 1 , and a sealing ring 10 is provided between the motor 8 and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com