Ejection type ductile PP fiber strengthened cement base composite material and preparation method thereof

A fiber-reinforced cement and composite material technology is applied in the field of fiber-reinforced cement-based composite materials and their preparation, and in the field of spray-type ductile fiber-reinforced cement-based composite materials and their preparation. The effect of low operating environment, strong toughness and low price

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] 23.5 parts of cement, 2.5 parts of rubber powder, 22 parts of fly ash, 20 parts of river sand (M=2.5-3.2), 15 parts of stones (particle size 5-10mm), 12 parts of water, 0.2 parts of powdered water reducer, 1.8 parts of redispersible latex powder, 1.5 parts of polypropylene fiber, and 1.5 parts of accelerator.

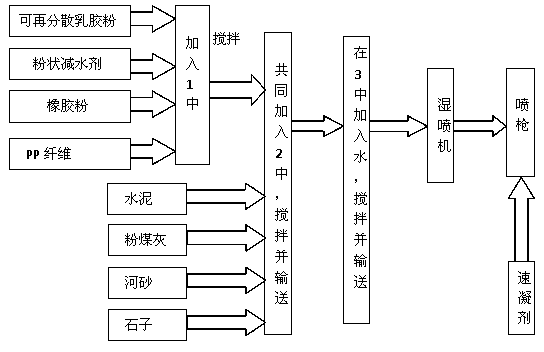

[0028] The preparation method of the spray-type ductile PP fiber-reinforced cement-based composite material, the steps by weight are as follows:

[0029] (1) One-time stirring: add redispersible latex powder, powdery water reducing agent, rubber powder and PP fiber into the mixer for dry stirring, the stirring time is 2 minutes, until the four base materials are stirred evenly; Bag the material, get the bagged mixture, and transport it to the construction site for use;

[0030] (2) Secondary stirring: take the bagged mixture obtained in step (1), add cement, fly ash, river sand and stones, put it into the first screw mixer, stir and transport it to the second sc...

Embodiment 2

[0034] 27 parts of cement, 1.9 parts of rubber powder, 26 parts of fly ash, 23.5 parts of river sand (M=2.5-3.2), 10 parts of stones (particle size 5-10mm), 7 parts of water, 0.2 parts of powdered water reducer, 1.6 parts of redispersible latex powder, 1.2 parts of polypropylene fiber, and 1.6 parts of accelerator.

[0035] The preparation method of the spray-type ductile PP fiber-reinforced cement-based composite material, the steps by weight are as follows:

[0036] (1) One-time stirring: Add the redispersible latex powder, powdery water reducing agent, rubber powder and PP fiber into the mixer for dry stirring, the stirring time is 3 minutes, until the four base materials are stirred evenly; Bag the material, get the bagged mixture, and transport it to the construction site for use;

[0037] (2) Secondary stirring: take the bagged mixture obtained in step (1), add cement, fly ash, river sand and stones, put it into the first screw mixer, stir and transport it to the second...

Embodiment 3

[0041] 22 parts of cement, 3 parts of rubber powder, 25.6 parts of fly ash, 19 parts of river sand (M=2.5-3.2), 14 parts of stones (particle size 5-10mm), 13 parts of water, 0.1 part of powdered water reducer, 1 part of redispersible latex powder, 1 part of polypropylene fiber, 1.3 part of accelerator.

[0042] The preparation method of the spray-type ductile PP fiber-reinforced cement-based composite material, the steps by weight are as follows:

[0043] (1) One-time stirring: Add the redispersible latex powder, powdery water reducing agent, rubber powder and PP fiber into the mixer for dry stirring, the stirring time is 3 minutes, until the four base materials are stirred evenly; Bag the material, get the bagged mixture, and transport it to the construction site for use;

[0044] (2) Secondary stirring: take the bagged mixture obtained in step (1), add cement, fly ash, river sand and stones, put it into the first screw mixer, stir and transport it to the second screw mixer,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com