Coreless paper roll rewinder with reliable winding and winding method

A rewinding machine and paper roll technology, applied in the field of rewinding machines, can solve the problems of increasing the manufacturing cost of rewinding machines, the difficulty of machine debugging, and increasing the difficulty of control, so as to reduce the difficulty of machine debugging, reliable winding, and lower requirements Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

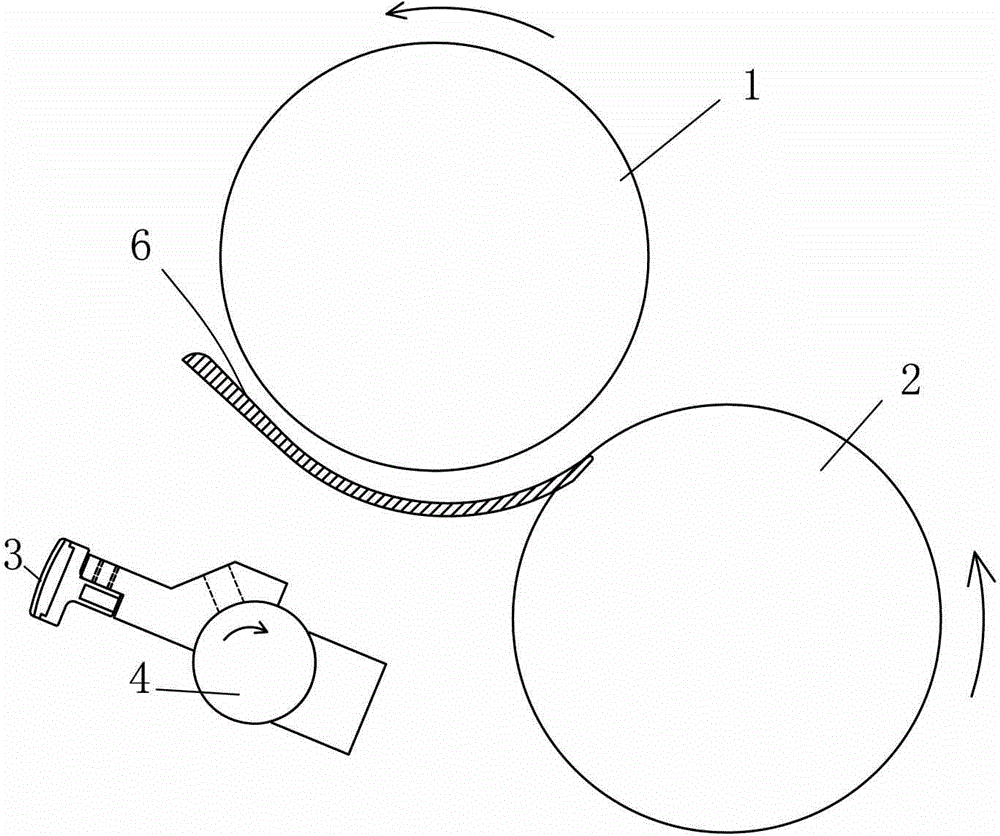

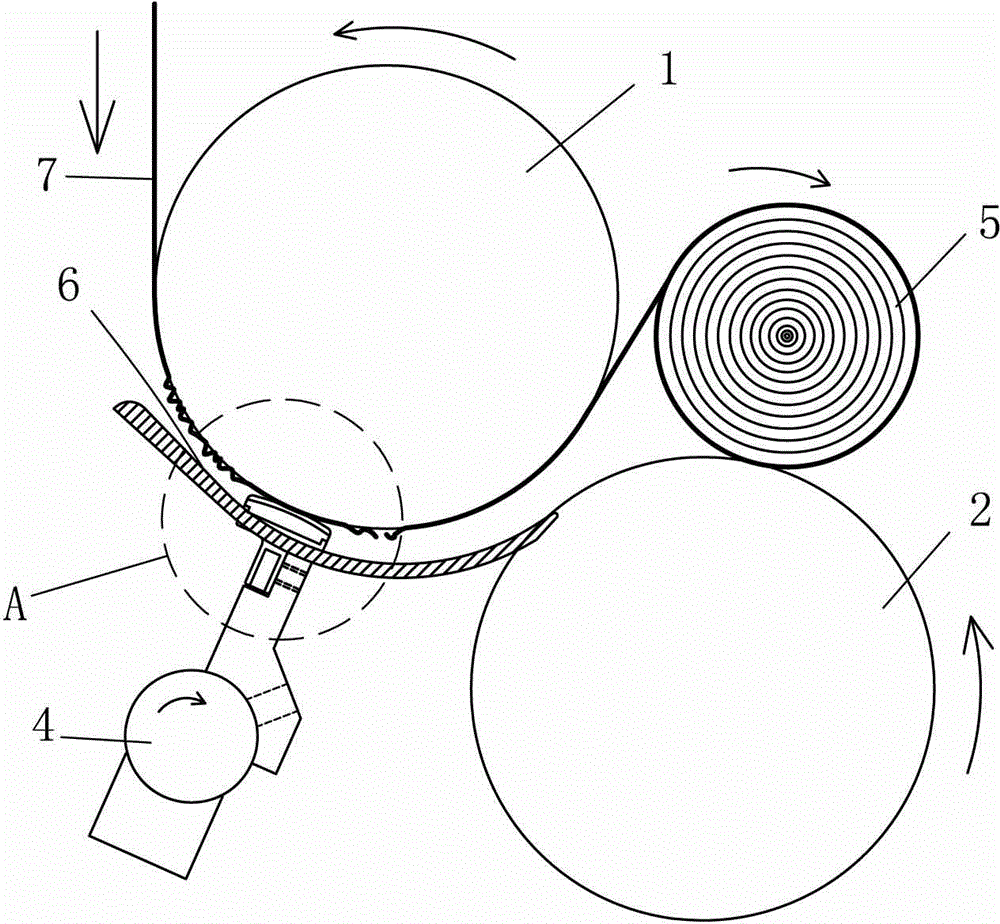

[0017] See figure 1 , A coreless paper rewinding machine according to the present invention includes an upper rewinding roll 1 and a lower rewinding roll 2. Below the upper rewinding roller 1 is provided a pressing member 3 for realizing a paper breaking action. During the paper break action, such as figure 2 As shown, the pressing member 3 rotates around the shaft 4, and the pressing member 3 touches the paper wound on the upper rewinding roller 1, so that the tail paper of the rewinding paper roll 5 is disconnected.

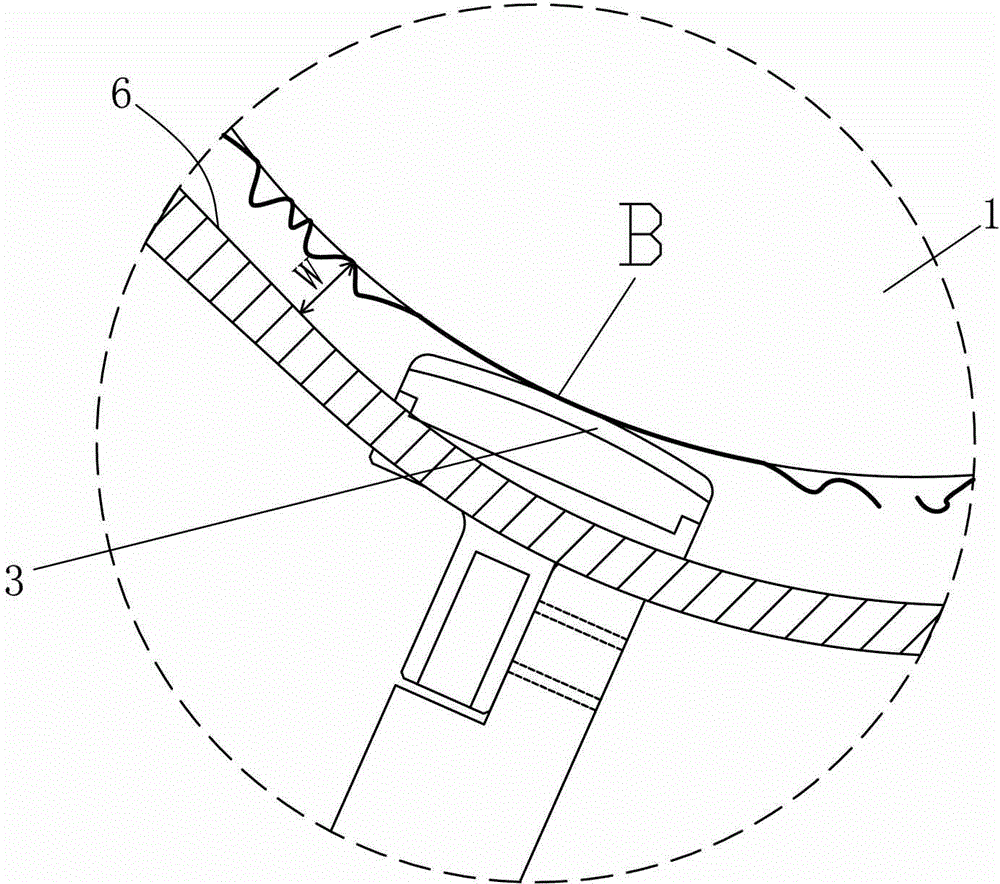

[0018] See figure 1 , Under the upper rewinding roller 1 is also provided a winding guide surface 6 close to the roller surface of the upper rewinding roller. See image 3 , The narrowest gap W between the unwinding guide surface 6 and the roller surface of the upper rewinding roller 1 is not more than 10 mm, and the paper travel direction is taken as the reference direction. The narrowest gap W is located at the contact pressure of the pressing member 3 on the p...

Embodiment 2

[0021] See Image 6 The difference between this embodiment and the first embodiment is that a plurality of suction ports 10 are added to the roll surface of the upper rewinding roll 1. These suction ports 10 can only take in air when rotated to the angle β. The effect is that the paper 7 is firmly adsorbed on the upper rewinding roller 1 within the range of the angle β, and the traction force of the upper rewinding roller 1 on the paper is enhanced. The other structure and unwinding process of this embodiment are the same as the first embodiment.

[0022] In the above embodiments, in order to avoid interference between the pressing member 3 and the winding guide surface 6, the winding guide surface 6 can be made Figure 7 In the comb-like structure shown, the winding guide surface is composed of a plurality of strip-shaped plates 6a arranged in parallel, and a gap 11 is left between each strip-shaped plate. when figure 2 The pressing member 3 shown turns to figure 2 In the pos...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com