Driving roller with coarse surface convenient to replace

A technology of driving rollers and rough surfaces, which is applied in the directions of winding strips, thin material handling, transportation and packaging, etc. It can solve the problems of uneconomical, uneconomical and inconvenient, and the replacement of rough surfaces of driving rollers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

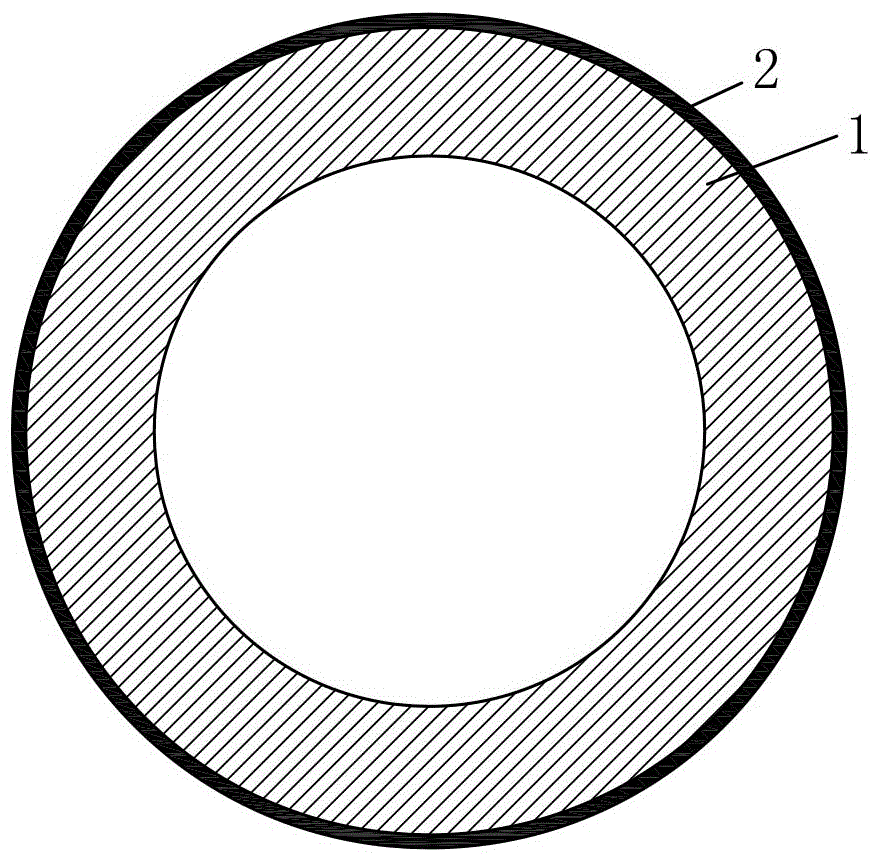

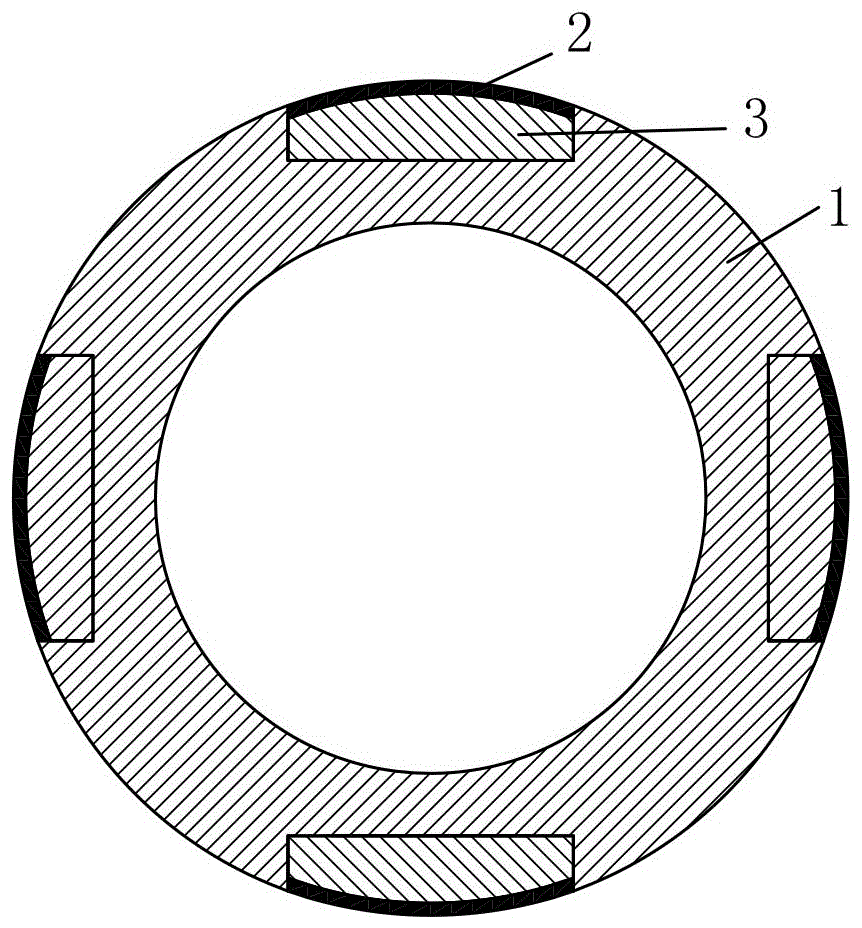

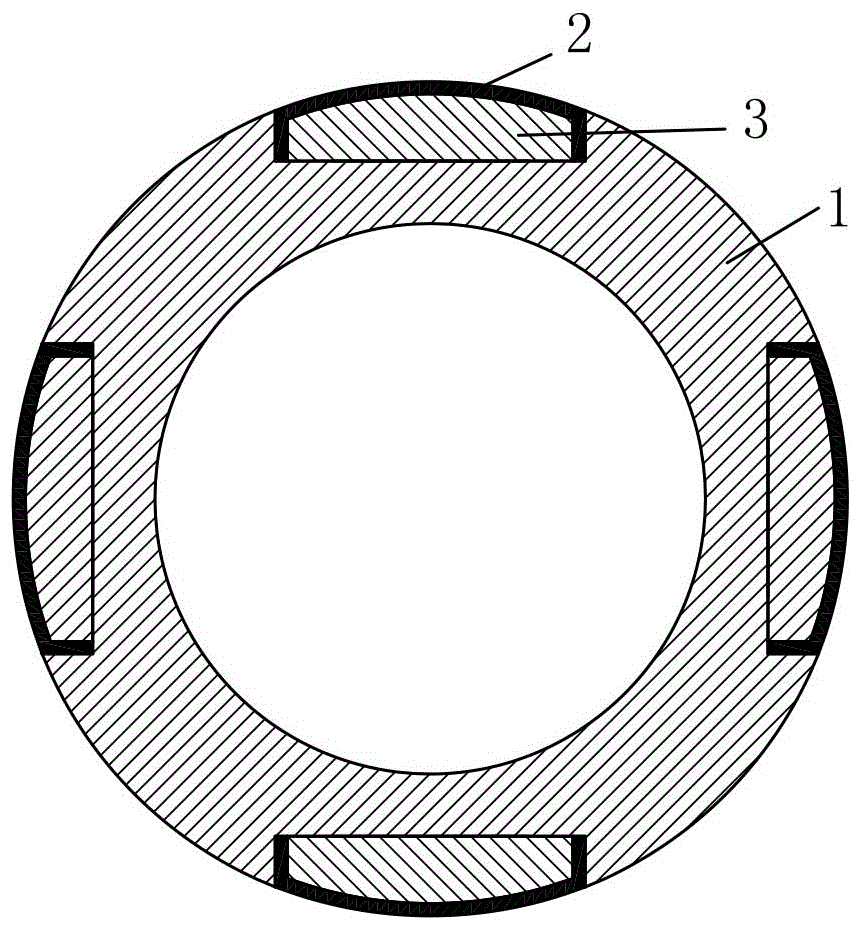

[0017] Figure 1 to Figure 5 Respectively represent the cross-section of the drive roller. exist figure 1 In the shown embodiment, the entire roller surface of the transmission roller 1 is pasted with sandpaper 2, the friction surface of the sandpaper 2 faces outward, and the friction surface of the sandpaper 2 is used as the rough surface of the transmission roller 1 . exist figure 2 In the shown embodiment, a detachable insert 3 is installed on the roller surface of the transmission roller 1, and the insert 3 is embedded in the pit body opened on the roller surface, and the sandpaper 2 is pasted on the insert 3, and the friction of the sandpaper 2 face outward. exist image 3 In the shown embodiment, the sandpaper 2 is not only pasted on the insert 3, but also the edge of the sandpaper 2 is sandwiched between the insert 3 and the pit body where the insert 3 is located. exist Figure 4 In the shown embodiment, the sandpaper 2 is not only pasted on the insert 3, but als...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com