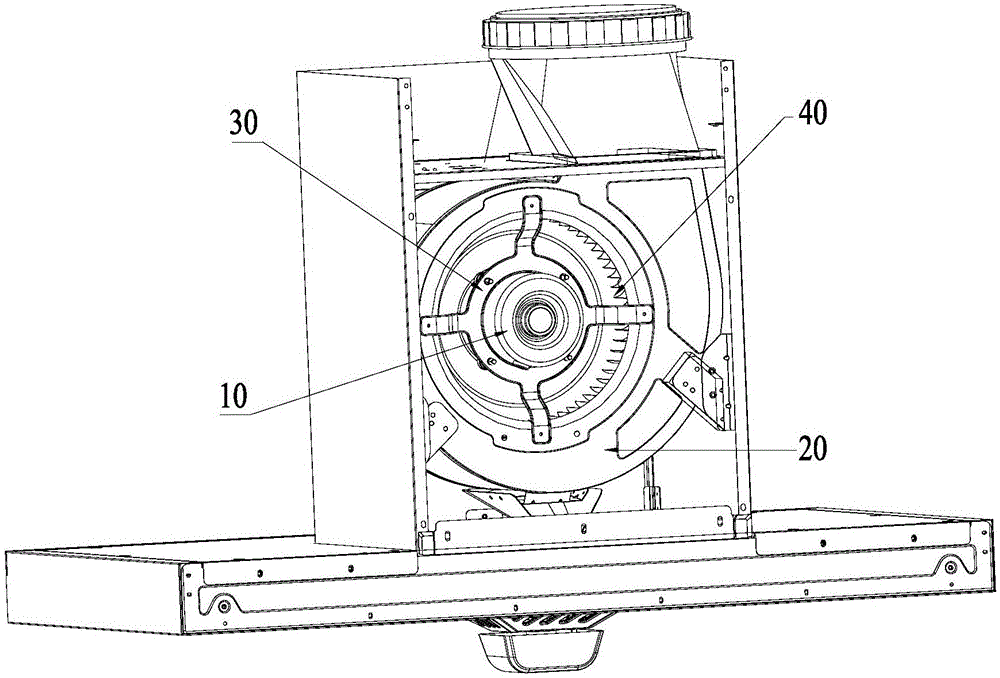

Mounting structure of range hood motor and range hood

A technology of installation structure and motor, which is applied in the field of range hoods, can solve problems such as difficult processing technology, increased air resistance, and increased noise, and achieve the effects of low processing technology requirements, reduced flow noise, and reduced vibration noise

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

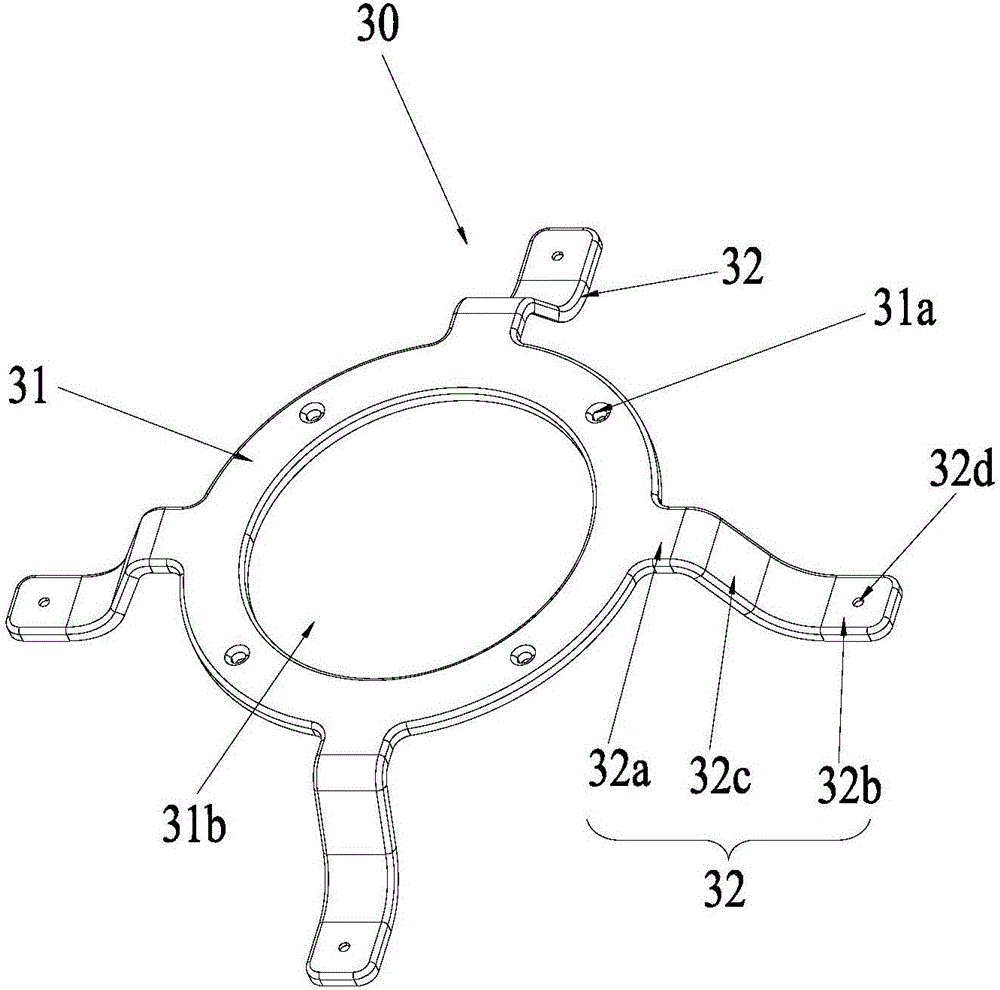

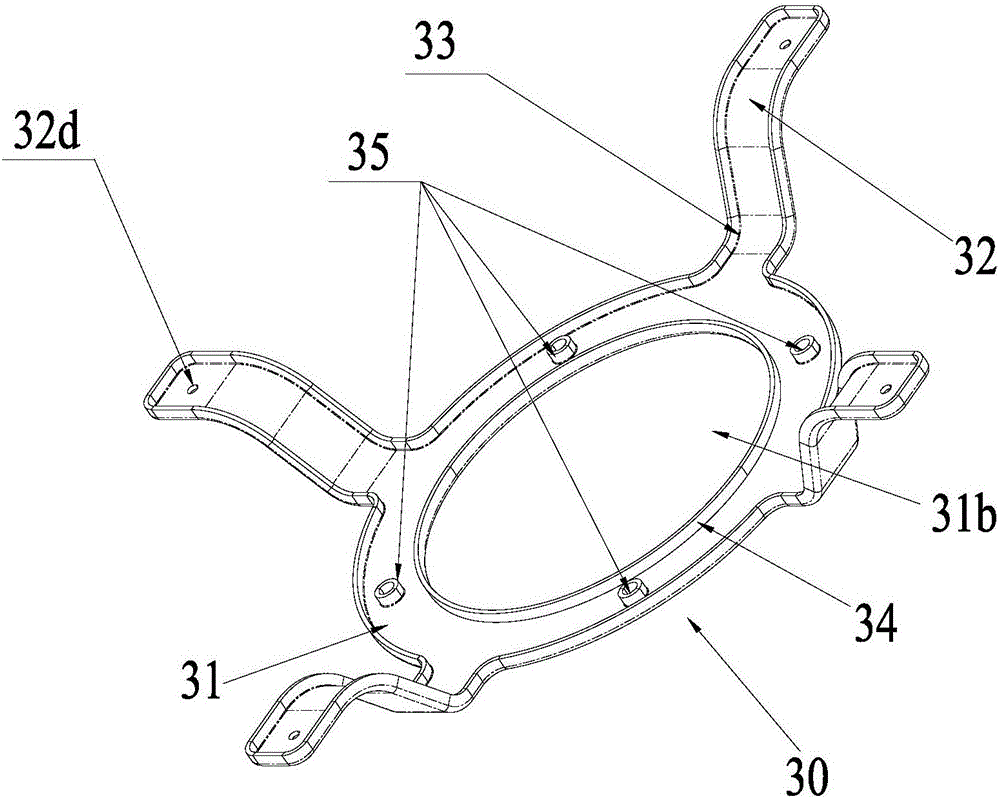

[0035] Specific embodiments of the present invention will be described in detail below in conjunction with the accompanying drawings. It should be understood that the specific embodiments described here are only used to illustrate and explain the present invention, and are not intended to limit the present invention.

[0036] In the present invention, in the case of no contrary description, the used orientation words such as "up, down, left and right" usually refer to the up, down, left and right shown in the accompanying drawings; "inside and outside" Refers to the inside and outside of the outline of each part itself.

[0037] As introduced in the background art, the centrifugal fan can generate relatively large wind pressure and air volume, but the noise generated by the centrifugal fan is also a difficult problem to solve. The noise of the centrifugal fan is mainly caused by vibration and air flow. Among them, the motor is the main source of noise in the centrifugal fan. ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com