High-gain low-profile null feed array antenna

A high-gain, antenna technology, applied in antennas, slot antennas, electrical components, etc., can solve the problems of inconvenient installation and portability of three-dimensional three-dimensional structures, and achieve the effect of reducing antenna efficiency, improving antenna efficiency, and reducing antenna side lobes

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

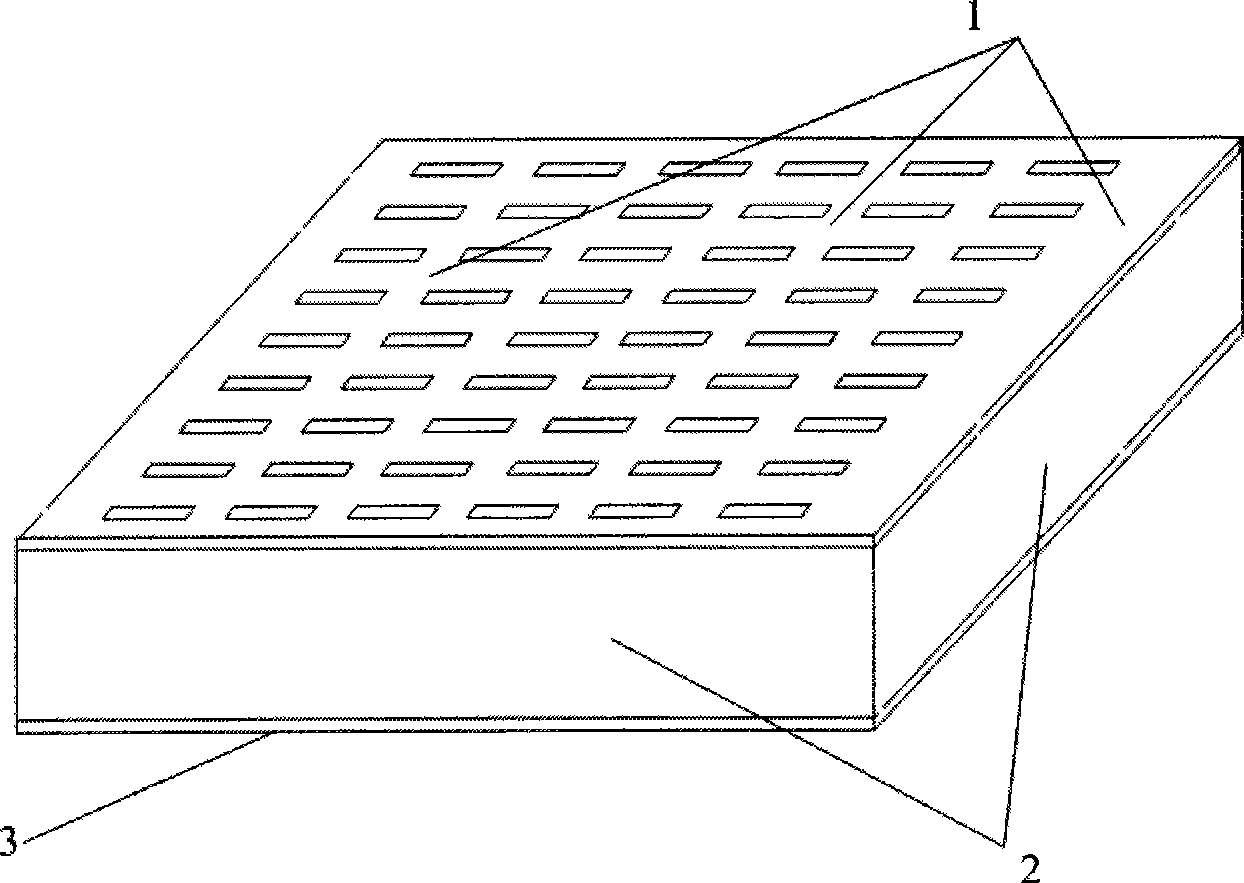

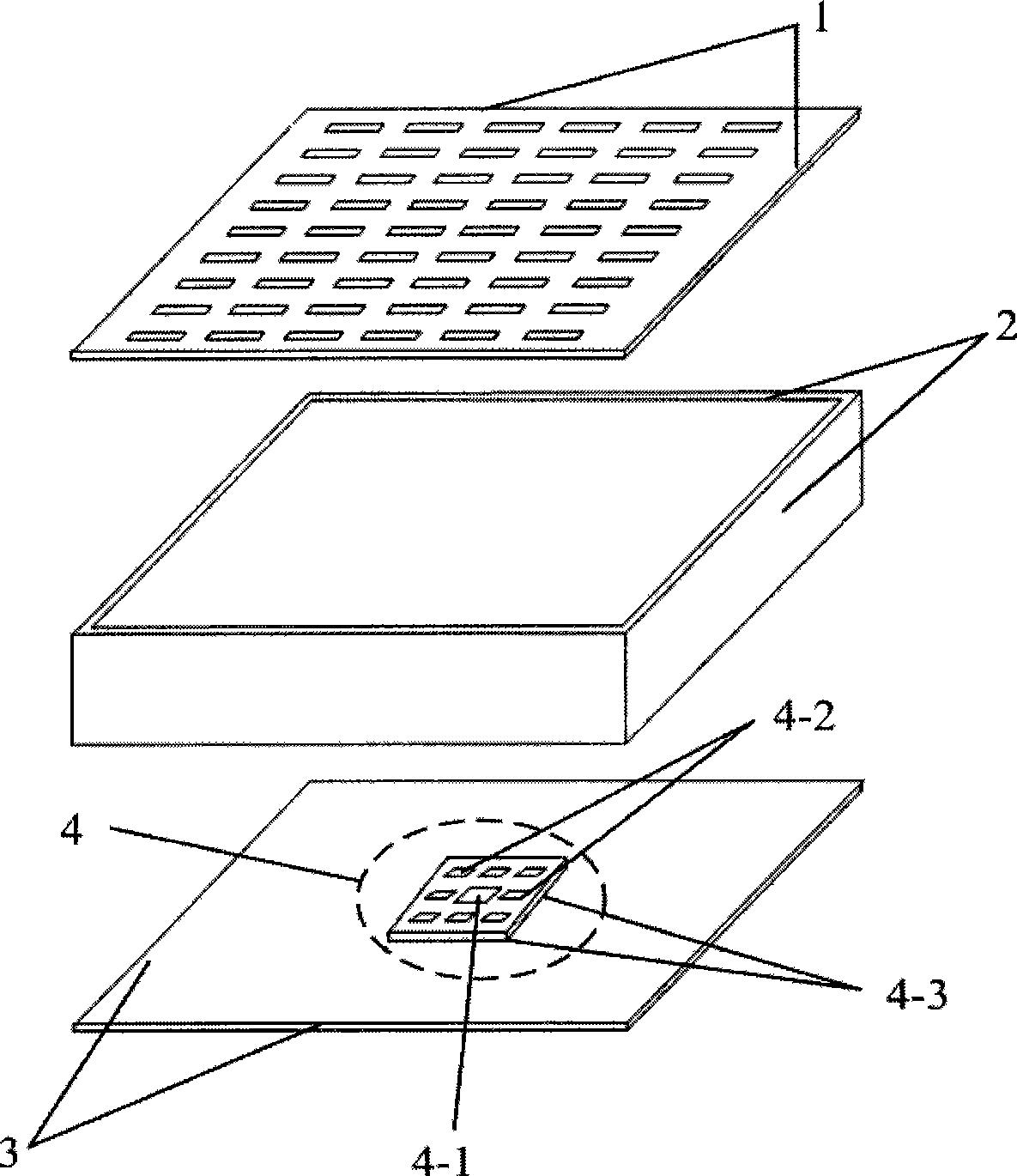

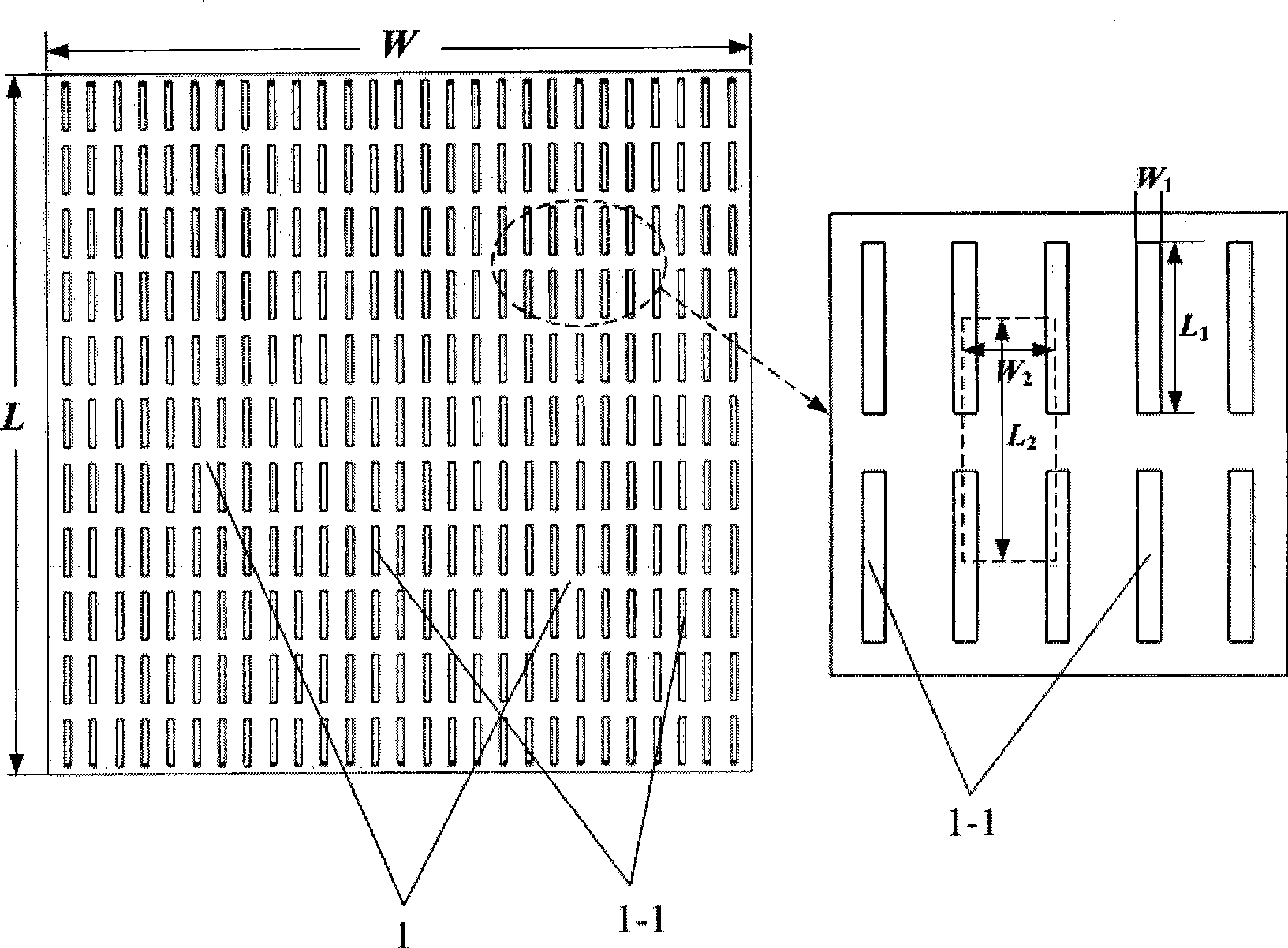

[0035] Adopt 1mm thick aluminum plate as the plate material of metal cover plate 1, metal side plate 2 and metal base plate 3; the peripheral dimensions of metal cover plate 1 and metal base plate 3 are the same: W=110mm, L=11mm; all on the metal cover plate 1 Gap unit 1-1 has the same size, and the structural parameter is W 1 = 1 mm, L 1 =7.5mm, W 2 = 4mm, L 2 = 10mm; the periphery of the metal side plate 2 is aligned with the metal cover plate 1 and the metal bottom plate 3 and forms a cavity, and the net height of the cavity is 11mm; the feed source patch 4-1 is printed on a layer with a thickness of 1mm and a relative dielectric constant On the dielectric substrate 4-3 of 2.2, the structural parameters of the dielectric substrate 4-3 are: W 3 =40mm, L 3 =40mm; the structural parameters of the feed patch 4-1 and the parasitic passive patch 4-2 are respectively taken as: W 4 =10mm, L 4 = 10mm, W 5 =7.5mm,L 5 =7.5mm, W 6 =13mm,L 6 =13mm; the feed connector 4-1-1 ado...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com