Flat belt driven dish type splitter

A disc separator and flat belt technology, applied in centrifuges and other directions, can solve the problems of decreased stability and reliability of the whole machine, multiple manufacturing technical requirements for parts, and concentrated latex mixed with gel, etc., and achieve continuous working time. The effect of prolonging, reducing processing technology requirements, and beautiful appearance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

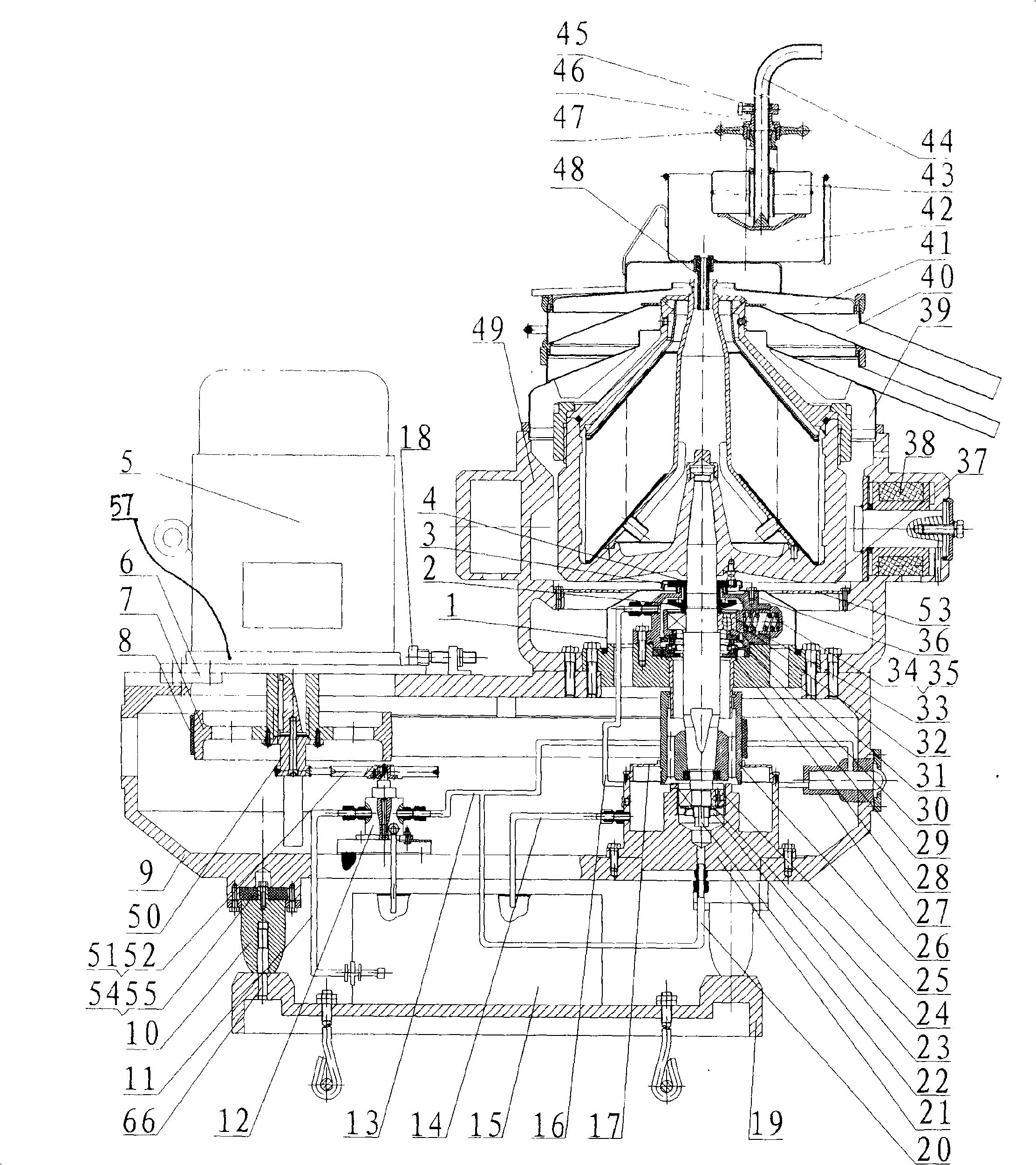

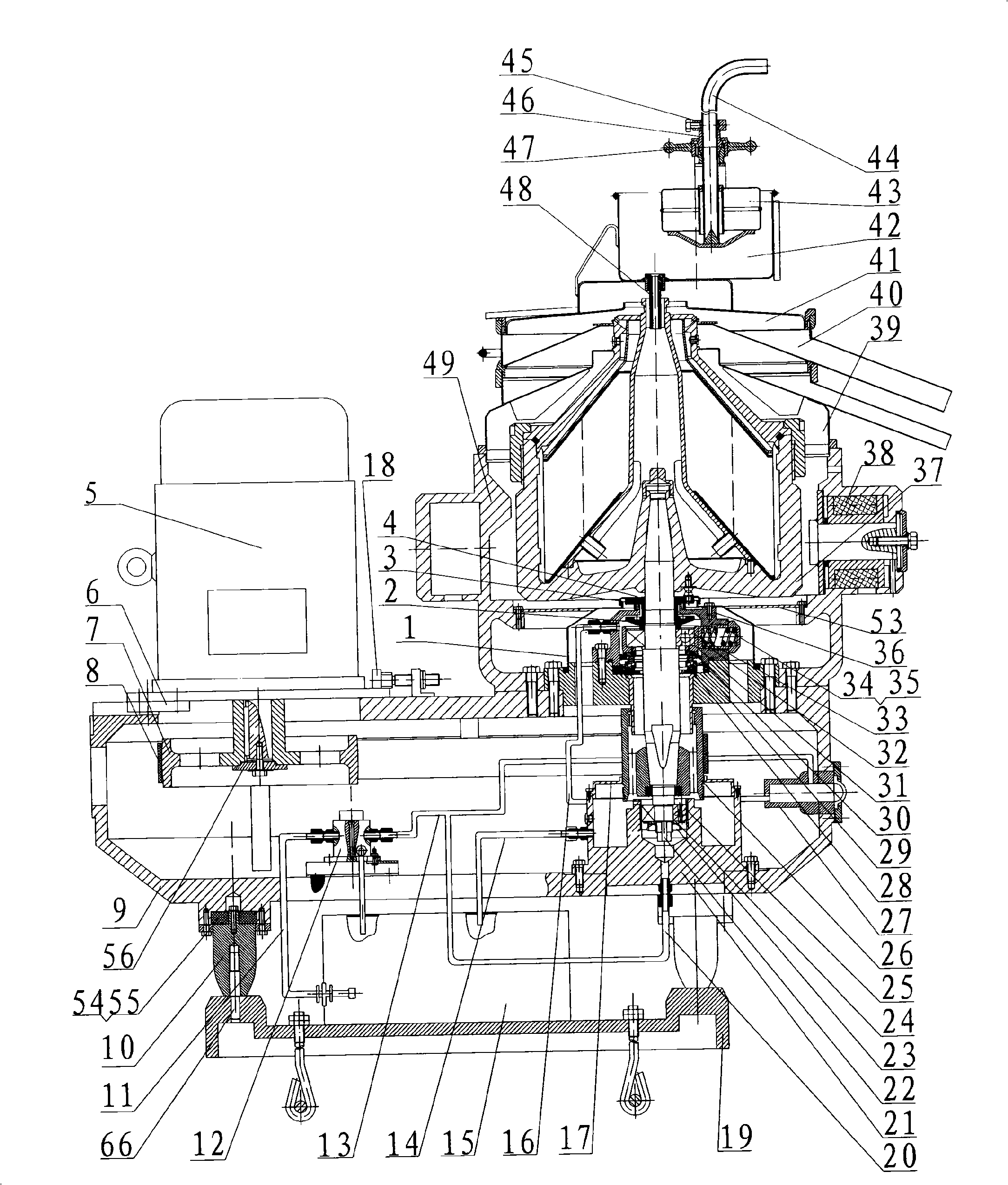

[0072] Latex Disc Separator with Drive / Electric Drive Gear Pump Oil Supply Lubrication

[0073] Such as figure 1 , figure 2 As shown, it is a latex separator for concentrating and separating natural rubber latex, and the disc is provided with a neutral hole. The latex raw material enters the high-speed rotating drum through the feeding pipe and the adjusting barrel, and the raw material is separated into concentrated latex (light phase) and latex (heavy phase) that meet the requirements of relevant standards, and is thrown out of the drum, and separated into the upper collector and output after being combined with the lower collector. Improvements to existing drum technology are as follows:

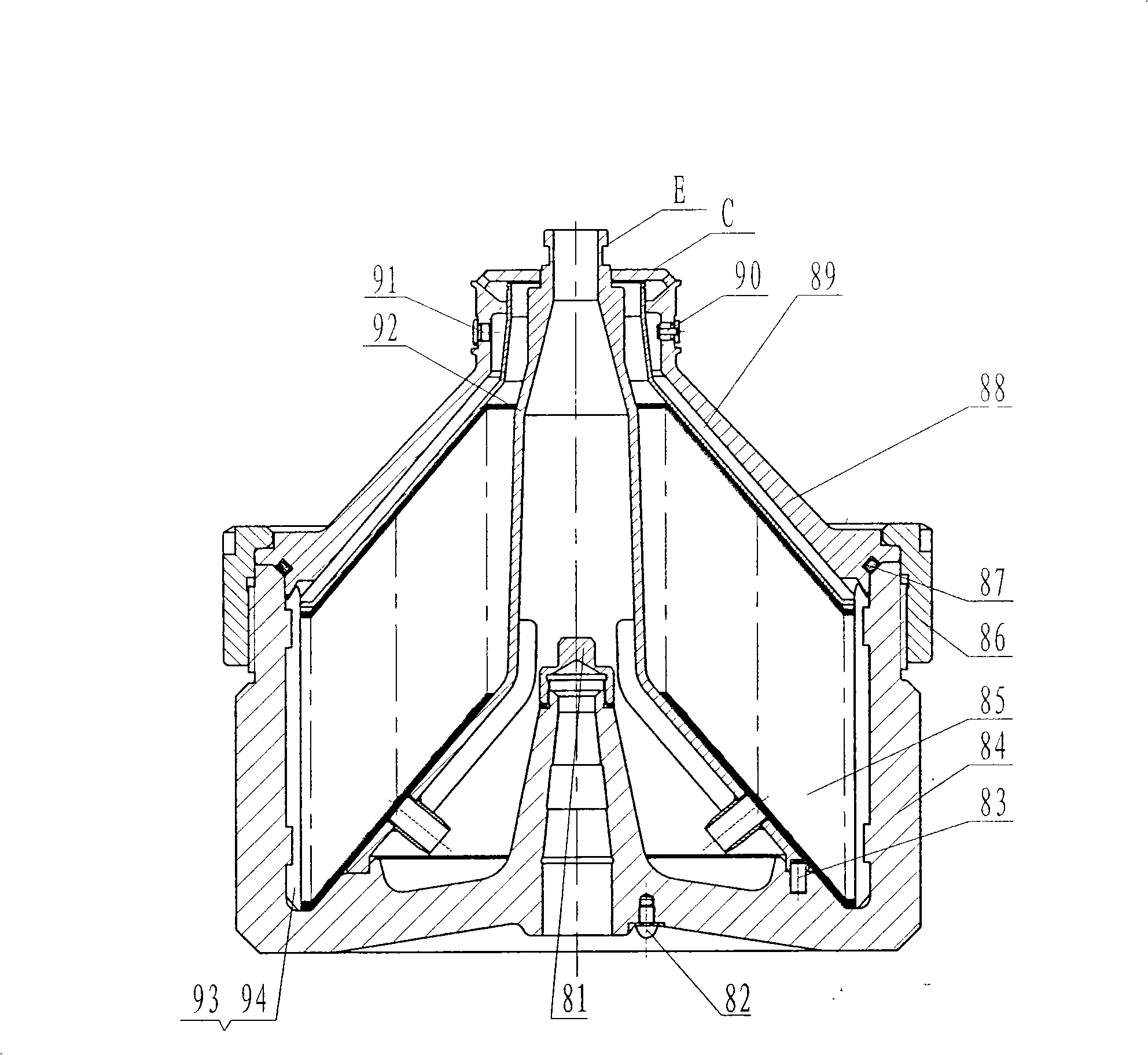

[0074] ①Increased slag holding space: After the drum of the latex separator has been running for a period of time, a ring-shaped gel ring will be formed in the lower cone surface of the feed horn 92, and it will gradually increase with the prolongation of the working time, so that It...

Embodiment 2

[0080] Belt drive / electric drive oil supply lubrication open manual slag discharge disc separator

[0081] Such as figure 1 , figure 2Shown, complete machine is by motor 5, flat belt drive (7,8,26), vertical shaft system and belt radial pressure axial force compensator (1~4,21~26,28~36), by small pulley 50, Large pulley 51, belt 52, oil inlet pipe 11, gear oil pump 12, upper oil inlet pipe 13, oil return pipe 14, oil tank 15, upper bearing oil inlet pipe 16, oil seal cover 17, lower bearing oil inlet pipe 20, oil mirror 27 constitute a lubrication system, Belt tensioning device 18, drum 37, feeding and discharging system (39-48), electromagnetic brake 38, wind gathering plate 53, base 19, outrigger 10, shock absorbing device (54, 55), lower body 9, upper Fuselage 49, frequency converter and electric control cabinet etc. are formed. The motor 5 is started by frequency conversion, which can ensure stable speed-up in the starting process and avoid excessive starting current. ...

Embodiment 3

[0085] Semi-enclosed artificial slag discharge disc separator

[0086] like Figure 8 As shown, the composition includes: motor 5, flat belt transmission (7, 8, 26), vertical shaft system and belt radial pressure axis force compensation device (1 ~ 4, 21 ~ 26, 28 ~ 36), small pulley 50, large Pulley 51, belt 52, oil inlet pipe 11, gear oil pump 12, upper oil inlet pipe 13, oil return pipe 14, oil tank 15, upper bearing oil inlet pipe 16, oil seal cover 17, lower bearing oil inlet pipe 20, oil mirror 27 constitute a lubrication system, and the belt Tensioning device 18, machine base 19, support leg 10, damping device (54,55), lower fuselage 9, light liquid centripetal pump 61, heavy liquid centripetal pump 62, rotating drum 59, upper casing 60, Bottom cover 58, inlet and outlet joint 63, liquid inlet pipe 66, heavy liquid output pipe 64, heavy liquid pressure adjustment device 65, light liquid output pipe 68, light liquid pressure adjustment device 67, inlet and outlet joint c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com